A gas flow field for a proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, which is applied to fuel cell parts, collectors/separators, etc., can solve problems such as water removal, uneven gas distribution, and large reaction gas resistance that affect the gas mass transfer in the cell. To achieve the effect of simple structure, uniform gas distribution and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

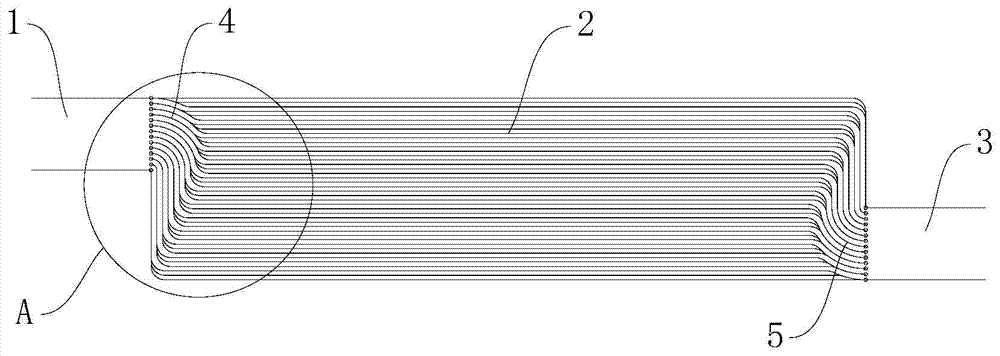

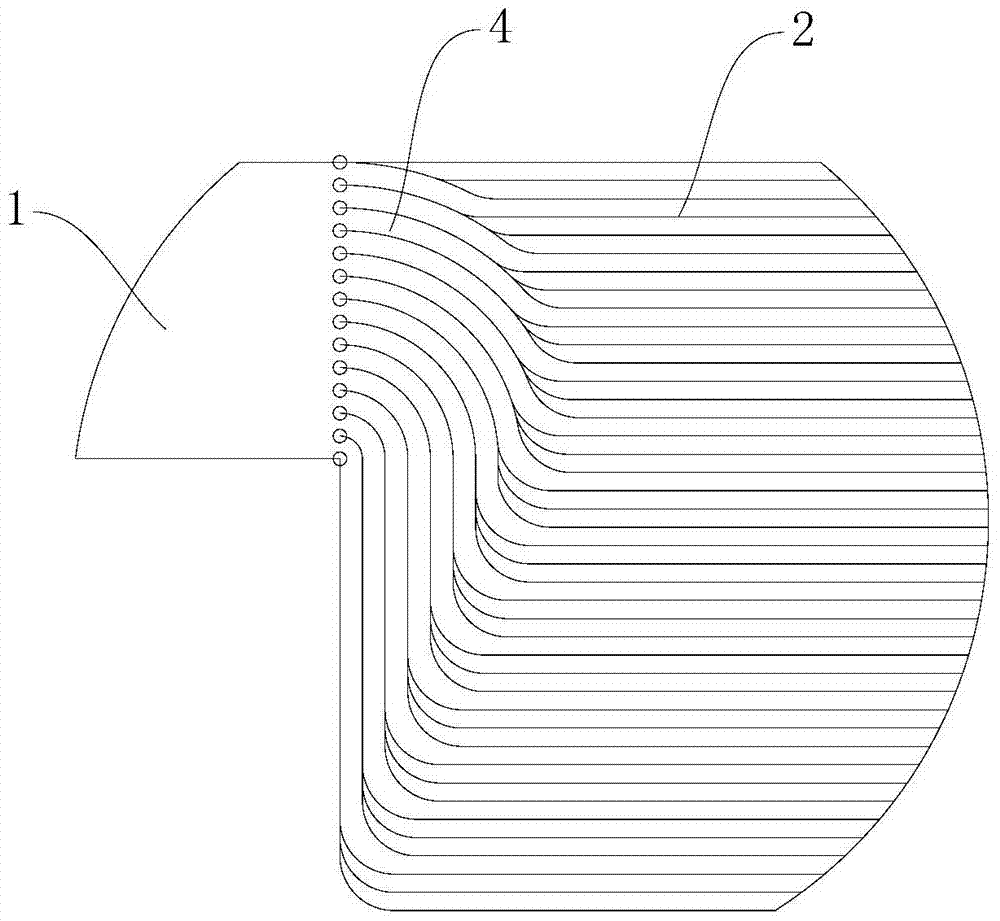

[0021] Combine below Figure 1 to Figure 3 And further illustrate the technical solution of the present invention through specific examples.

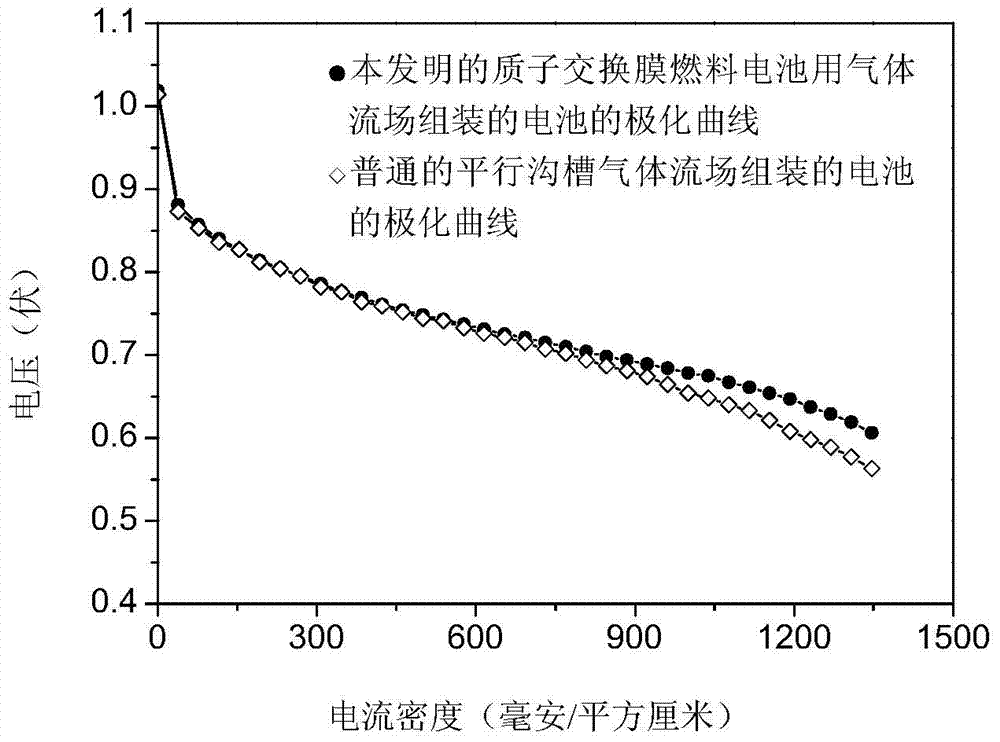

[0022] A gas flow field for a proton exchange membrane fuel cell, comprising a reaction gas inlet 1, a parallel groove flow field section 2 and a reaction gas outlet 3, and a first distribution device is arranged between the reaction gas inlet 1 and the parallel groove flow field section 2 The flow field section 4, the second distribution flow field section 5 is arranged between the reaction gas outlet 3 and the parallel groove flow field section 2, and the first distribution flow field section 4 and the second distribution flow field section 5 are formed by parallel streamlined grooves. The corners between the first distribution flow field section 4, the second distribution flow field section 5 and the parallel groove flow field section 2 are all streamlined, such as figure 1 and figure 2 shown. The first distribution flow field se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com