A multi-core wire stripping pre-tin cutting machine

A cutting machine, multi-core wire technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problems of high labor costs, large differences in work quality, and low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

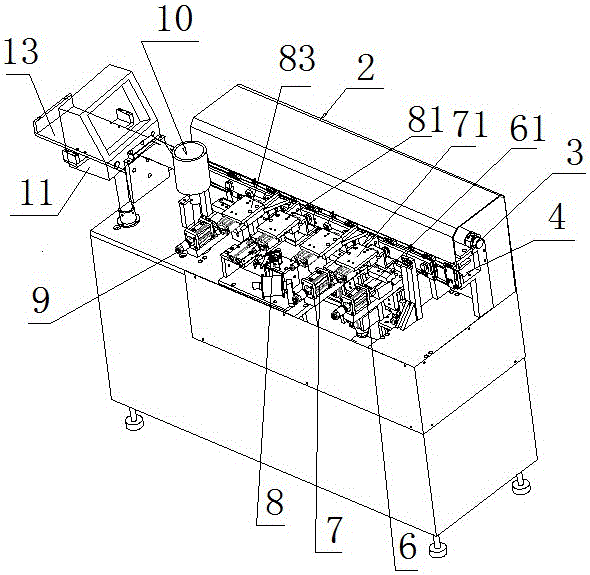

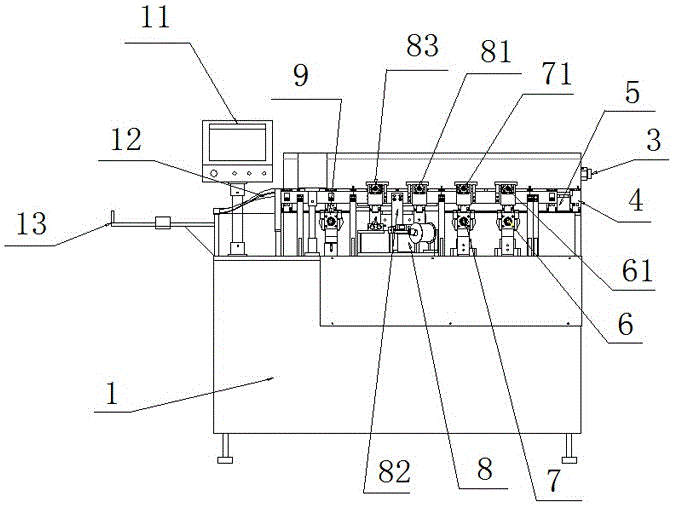

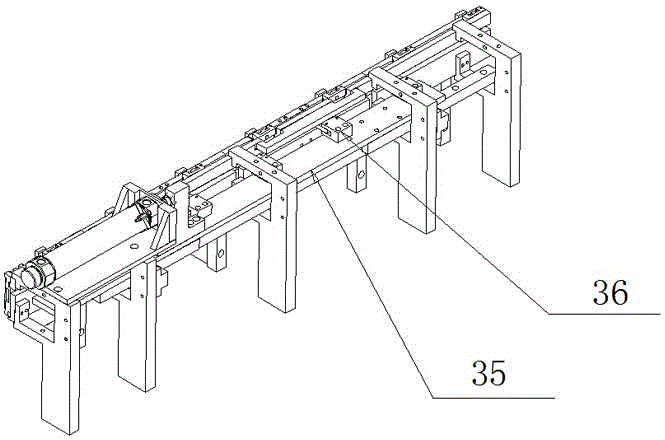

[0023] In this example, if Figure 1 to Figure 10 As shown, a multi-core wire stripping pre-tin cutting machine of the present invention includes a chassis power distribution cabinet 1, and a wire passing platform 2 arranged on the rear end of the chassis power distribution cabinet 1, and is arranged in front of the wire passing platform 2 The moving track mechanism 3 at the top, and the clamping clamp 4 slidably arranged on the moving track mechanism 3, and the optical fiber sensing position 5 set in front of the clamping clamp 4, and the round wire stripping mechanism set on the left side of the optical fiber sensing position 5 6. A round wire positioning mechanism 61 is connected to the round wire peeling mechanism 6, and a flat wire peeling mechanism 7 is arranged on the left side of the round wire peeling mechanism 6, and a flat wire positioning mechanism 71 is connected to the flat wire peeling mechanism 7 , and the flux circulation and tin-feeding mechanism 8 arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com