Production line calibration comprehensive test method and production line calibration comprehensive test device

A comprehensive test and production line technology, applied in telephone communication, electrical components, branch office equipment, etc., can solve problems such as poor contact, affecting the test pass rate of mobile phone RF calibration comprehensive test, improper antenna matching, etc., to improve quality and improve comprehensive Test pass rate and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

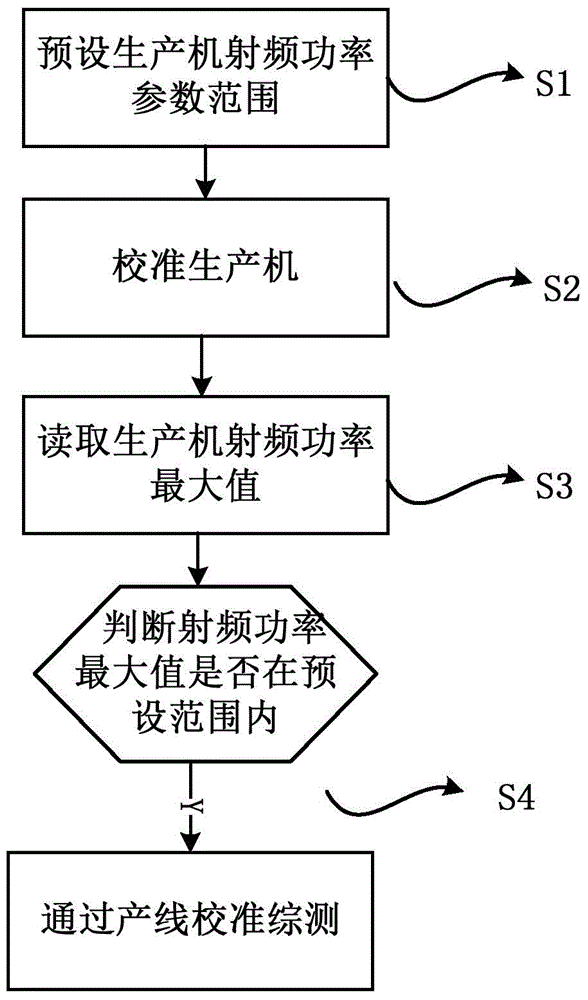

Embodiment 1

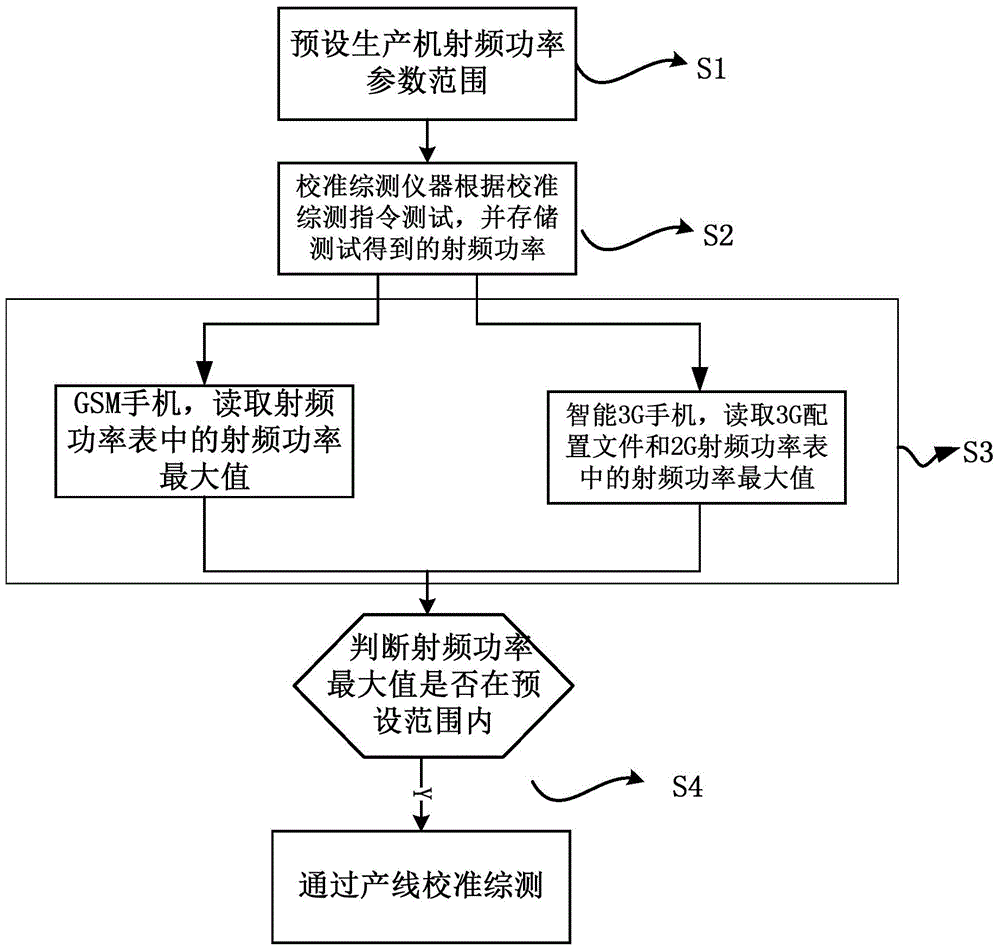

[0035] figure 2 It is an operation flowchart of a production line calibration comprehensive test method of the present invention, in figure 1On the basis of determining the type of the production machine, when the production machine is a GSM mobile phone, the step S3 also includes a process: reading the maximum value of the radio frequency power of each frequency band in the radio frequency power table of all frequency bands of the production machine, And extract the maximum value of the radio frequency power among all the maximum values. Only read the maximum RF power value from the mobile phone that has the greatest impact on the calibration comprehensive test results as the judgment condition for whether the production machine passes the production line calibration comprehensive test, which can greatly speed up the work efficiency, and at the same time ensure the power consistency of the production machine to avoid Batch rework caused by calibration power exceeding standa...

Embodiment 2

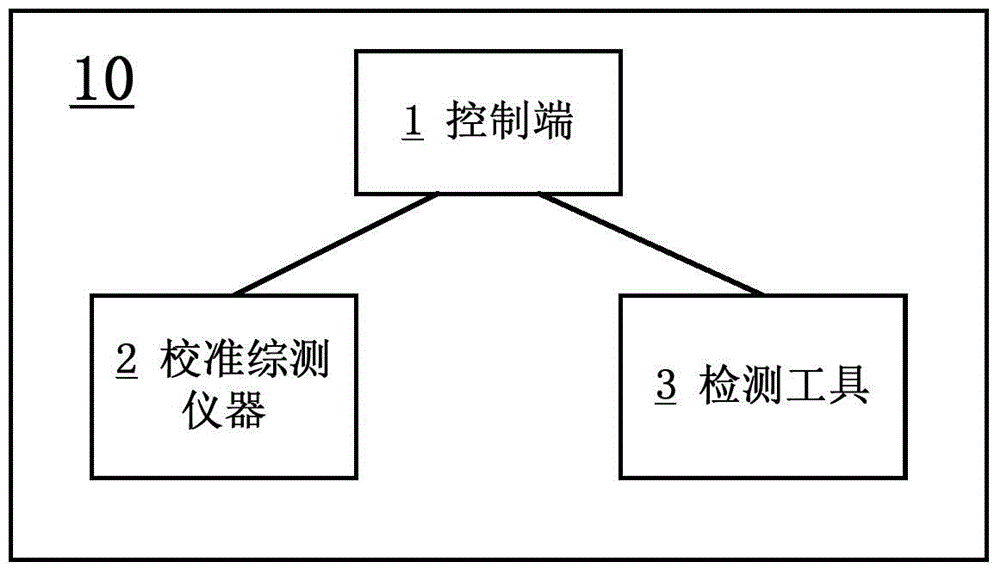

[0045] image 3 It is a schematic diagram of a production line calibration comprehensive testing device of the present invention, the calibration comprehensive testing device 10 includes a control terminal 1 for presetting the range of radio frequency power parameters of the production machine, a calibration comprehensive testing instrument 2 for calibrating the production machine, and a A detection tool 3 that reads the maximum value of the RF power of the production machine and compares the maximum value of the RF power with the preset range of RF power parameters.

[0046] Because the present invention directly reads the maximum value of radio frequency power that is not interfered by the test environment inside the production machine, it can avoid power loss due to factors such as lines, fixtures, instrument end connectors, antenna matching, etc. in the mobile phone radio frequency test system. Affect the result of mobile phone calibration, leading to the problem of calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com