Nano-zinc oxide feeding silkworm rearing method for manufacturing high-performance silk and product thereof

A nano-zinc oxide, high-performance technology, applied in silk fiber production, textiles and papermaking, textiles, etc., can solve the problems of unprovided silk mechanical properties, decreased silk quality and yield, and minimal modification effect. The effect of removing equipment support, good antibacterial and UV resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

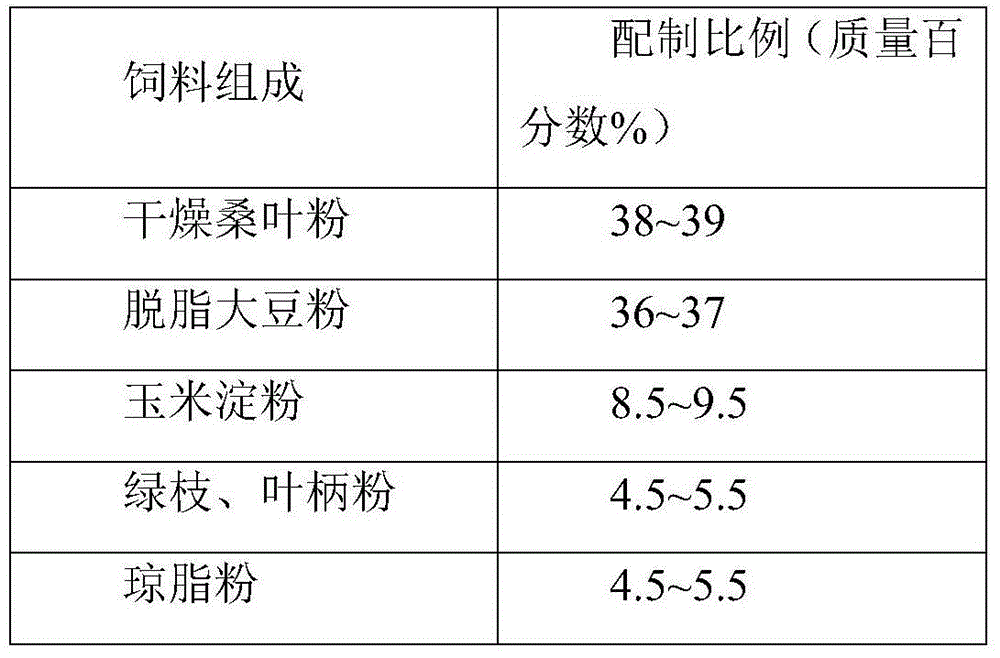

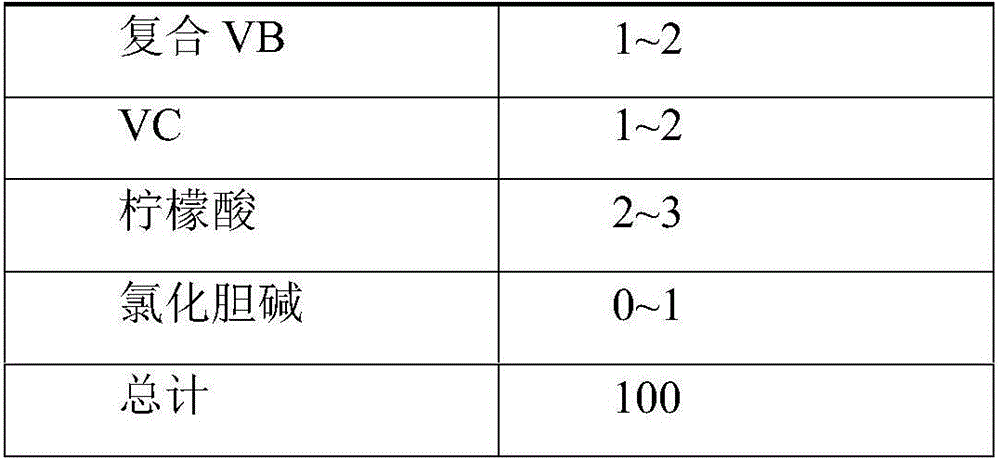

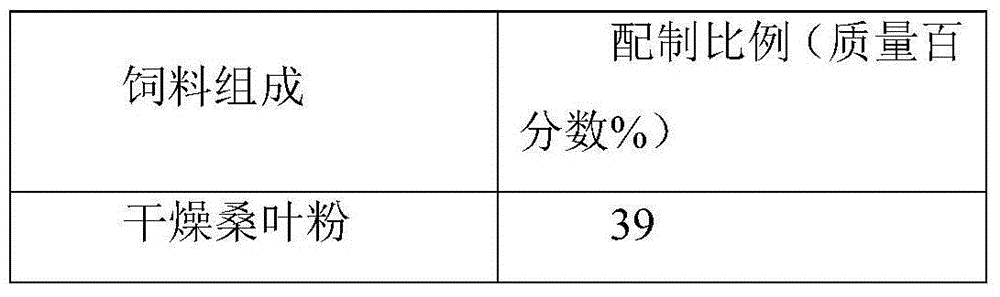

[0038] A kind of method for raising silkworms by adding food to nano-zinc oxide for preparing high-performance silk, at first preparing compound feed, specifically:

[0039] (1) dissolving nano-zinc oxide with a size range of 40 to 200nm in water to make a nano-zinc oxide solution;

[0040] (2) Ultrasonic the nano-zinc oxide solution for 15 minutes to disperse the nanoparticles evenly, stir the nano-zinc oxide solution and silkworm feed evenly, then put it into a microwave oven and heat it for 3 minutes. Feed; Wherein, the quality of water is 2 times of silkworm feed;

[0041] Then add nano-zinc oxide to silkworm artificial feed, that is, silkworm feed, and feed silkworms. The silkworm absorbs nano-zinc oxide and enters the silk gland, and finally combines nano-zinc oxide into silk during the spinning process to obtain high-performance silk;

[0042] Specifically: the silkworms were fed silkworm feed without adding nano-zinc oxide from the first to the fourth instar, and the ...

Embodiment 2

[0052] A kind of method for raising silkworms by adding food to nano-zinc oxide for preparing high-performance silk, at first preparing compound feed, specifically:

[0053] (1) dissolving nano-zinc oxide with a size range of 40 to 200nm in water to make a nano-zinc oxide solution;

[0054] (2) Ultrasonic the nano-zinc oxide solution for 30 minutes to disperse the nanoparticles evenly, stir the nano-zinc oxide solution and silkworm feed evenly, then put it into a microwave oven and heat it for 6 minutes. Feed; Wherein, the quality of water is 3 times of silkworm feed;

[0055] Then add nano-zinc oxide to silkworm artificial feed, that is, silkworm feed, and feed silkworms. The silkworm absorbs nano-zinc oxide and enters the silk gland, and finally combines nano-zinc oxide into silk during the spinning process to obtain high-performance silk;

[0056] Specifically: the silkworms were fed the silkworm feed without adding nano-zinc oxide from the first to the fourth instar, and ...

Embodiment 3

[0065] A kind of method for raising silkworms by adding food to nano-zinc oxide for preparing high-performance silk, at first preparing compound feed, specifically:

[0066] (1) dissolving nano-zinc oxide with a size range of 40 to 200nm in water to make a nano-zinc oxide solution;

[0067] (2) Ultrasonic the nano-zinc oxide solution for 20 minutes to disperse the nanoparticles evenly, stir the nano-zinc oxide solution and silkworm feed evenly, then put it into a microwave oven and heat it for 4 minutes. Feed; Wherein, the quality of water is 2.5 times of silkworm feed;

[0068] Then add nano-zinc oxide to silkworm artificial feed, that is, silkworm feed, and feed silkworms. The silkworm absorbs nano-zinc oxide and enters the silk gland, and finally combines nano-zinc oxide into silk during the spinning process to obtain high-performance silk;

[0069] Specifically: the silkworms were fed the silkworm feed without adding nano-zinc oxide from the first to the fourth instar, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size range | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Fracture energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com