Device system for using low temperature condensation method to remove VOC (volatile organic compound)

A technology of low temperature condensation and energy recovery device, applied in the direction of vapor condensation, separation method, chemical instrument and method, etc., can solve the problems of complex system, need for liquid nitrogen, high investment, and achieve good economy, cost saving and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

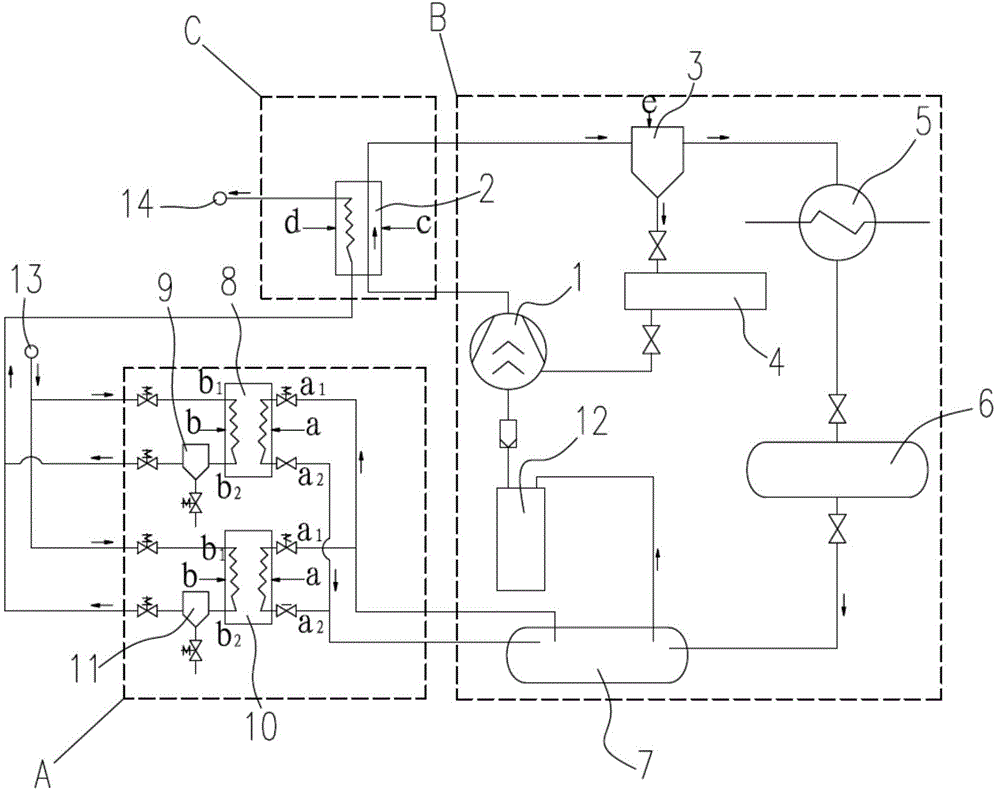

[0028] Such as figure 1 As shown, in this embodiment, the VOC removal module A includes a first evaporator 8, a second evaporator 10, a first gas-liquid separator 9, a second gas-liquid separator 11, and a refrigeration module B includes a refrigerant Compressor 1, refrigerant oil separator 3, air-cooled oil cooler 4, condensing device 5, high-pressure accumulator 6, low-pressure accumulator 7, refrigerant gas-liquid separator 12, energy recovery module C includes energy recovery device 2.

[0029] Such as figure 1 As shown, the inlet of the refrigerant compressor 1 is connected to the outlet of the refrigerant gas-liquid separator 12, the outlet of the refrigerant compressor 1 is connected to the inlet of the refrigerant side c of the energy recovery device 2, and the refrigerant of the energy recovery device 2 The outlet of side c is connected with the inlet of the refrigerant oil separator 3, the outlet of the refrigerant side e of the oil separator 3 is connected with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com