Synthesis method of silicoaluminophosphate molecular sieve SAPO-34

A technology of SAPO-34 and synthesis method, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of high template price, high cost, unfavorable industrial production and promotion, etc., and achieve high-efficiency recycling , avoid pollution, novel and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

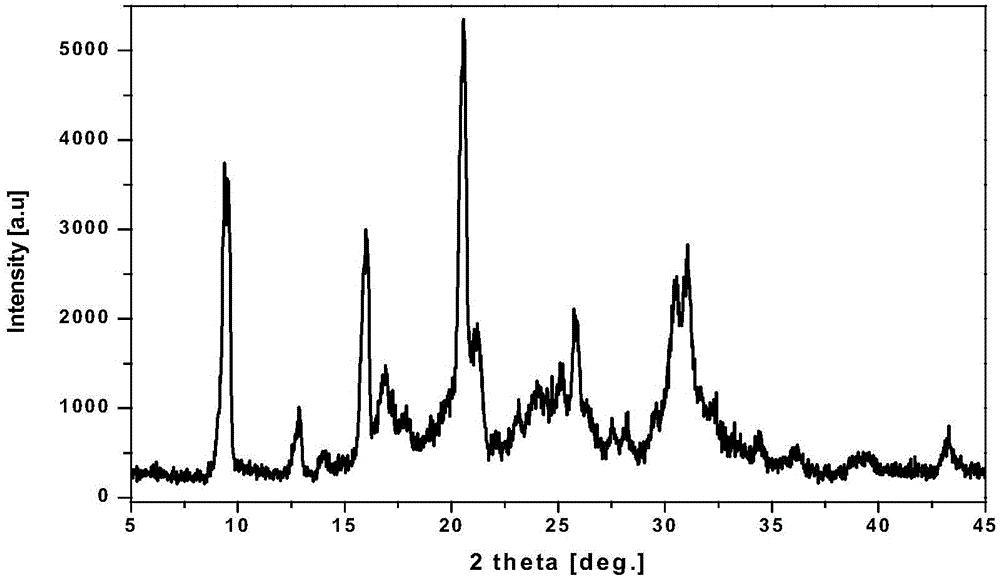

[0015] 8. Add 301g of phosphoric acid with a mass percentage of 85% to 31g of the mother liquor synthesized by using triethylamine as a template agent. After mixing evenly, slowly add 5.505g of pseudo-boehmite (Al2O3 mass percentage is 66.7%), and then fully stir evenly for about 2h; then add 2.28g of silica sol (SiO2 mass percentage is 30%) and stir thoroughly, while stirring, use organic template triethylamine or other to adjust the pH of the colloid to 6.0-7.0, about 8.0ml of triethylamine is used. Stir well, then put it into a crystallization kettle for hydrothermal dynamic crystallization at 200°C for 24 hours, filter, wash and dry the product, and XRD phase analysis shows that it is a pure phase SAPO-34 molecular sieve (see figure 1 ) is 105% relative to the crystallinity synthesized without mother liquor.

Embodiment 2

[0017] 8.301g of phosphoric acid with a mass percentage of 85% was added to 31g of the mother liquor synthesized with tetraethylammonium hydroxide as a template, and after mixing evenly, 5.505g of pseudo-boehmite (Al2O3 with a mass percentage of 66.7%) was slowly added, and then fully Stir evenly for about 2 hours; then add 2.28g of silica sol (SiO2 mass percentage is 30%) and stir thoroughly, while stirring, use organic template tetraethylammonium hydroxide or other to adjust the pH value of the colloid to about 7.5, about 12ml TEAOH ( TEAOH mass percent is 35%). Stir well, then put it into a crystallization kettle for hydrothermal dynamic crystallization at 200°C for 24 hours, after the product is filtered, washed, and dried, XRD phase analysis shows that the crystallinity of SAPO-34 molecular sieve is pure phase compared to that synthesized without mother liquor is 110%.

Embodiment 3

[0019] 8. Add 301g of phosphoric acid with a mass percentage of 85% to 31g of the mother liquor synthesized with morpholine as a template agent, mix well and slowly add 5.505g of pseudo-boehmite (Al2O3 mass percentage is 66.7%), and then fully stir for about 2 hours ; Then add 2.28g of silica sol (SiO2 mass percentage is 30%) and stir well, while stirring, use organic template tetramorpholine or other to adjust the pH value of the colloid to about 7.5, and about 5ml of morpholine (TEAOH mass percentage is 35% ). Stir well, then put it into a crystallization kettle for hydrothermal dynamic crystallization at 200°C for 24 hours, after the product is filtered, washed, and dried, XRD phase analysis shows that the crystallinity of SAPO-34 molecular sieve is pure phase compared to that synthesized without mother liquor was 112%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com