Sludge treatment method and system

A sludge treatment and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high treatment cost, unsatisfactory heavy metal treatment effect, and complex treatment technology. , to simplify the operation process, reduce the cost of sludge treatment, and achieve good process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

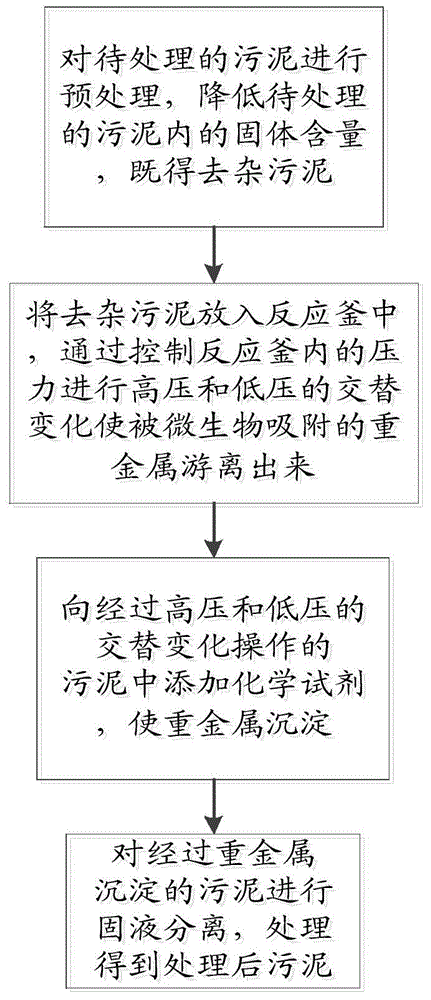

[0050] refer to figure 1 , figure 2 , the present embodiment provides a sludge treatment method, comprising the following steps:

[0051] First: Pretreatment of the sludge to be treated to remove solid impurities in the sludge to be treated, so as to get the impurity-removed sludge. Second: Put the impurities-removed sludge into the reactor, and control the pressure in the reactor to alternately change the high pressure and low pressure to free the heavy metals adsorbed by the microorganisms. Third: Add chemical reagents to the second treated sludge to precipitate heavy metals. Fourth: Then, solid-liquid separation is performed on the settled sludge, and treated sludge is obtained.

[0052] First, sludge is treated to remove impurities. Since there are usually various stones, branches, metal plates, etc. in the sludge, these impurities will affect the transportation of the sludge and affect the treatment of the sludge. Therefore, when the sludge is processed in the next ...

Embodiment 2

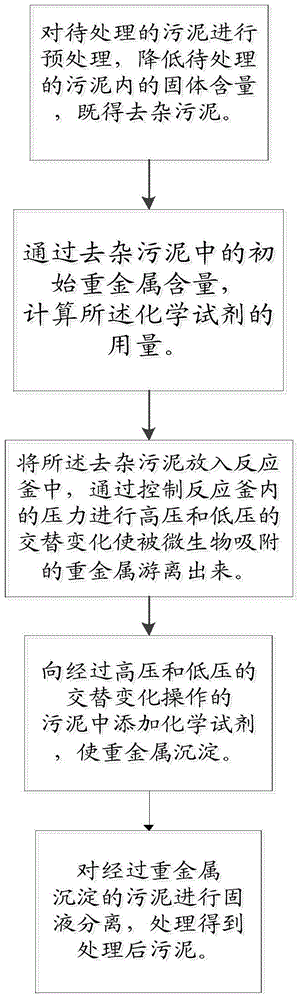

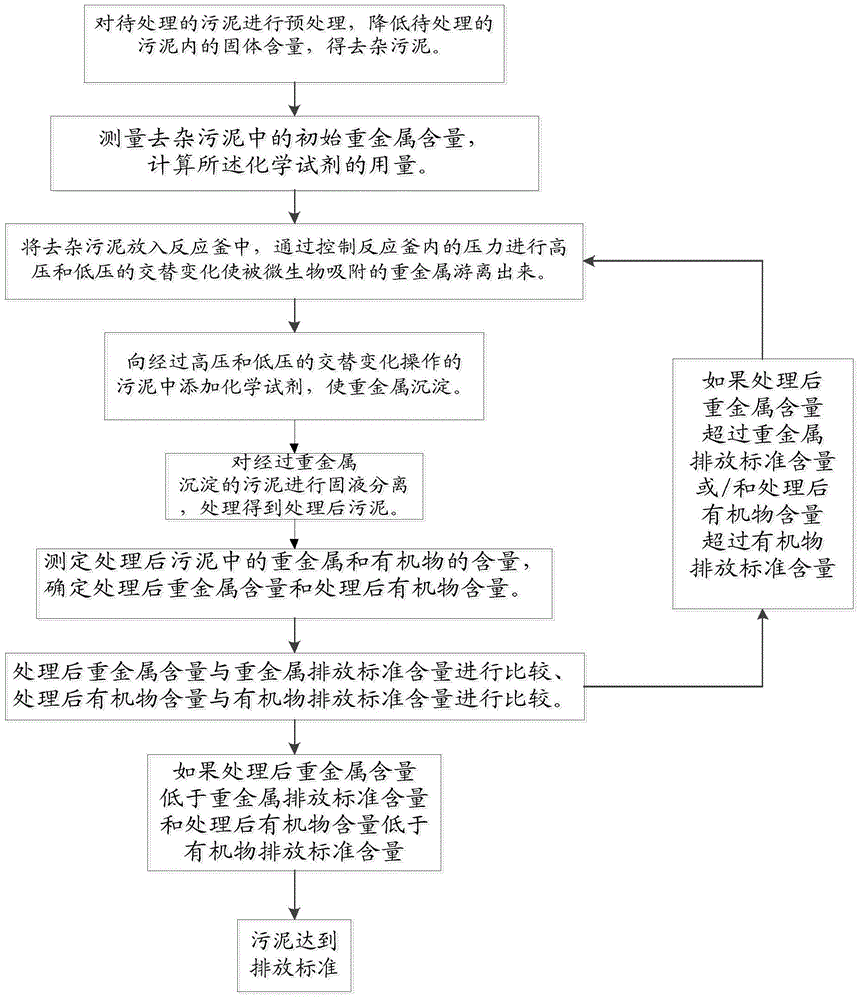

[0058] refer to image 3 , the present embodiment provides a sludge treatment method, comprising the following steps:

[0059] First: pretreat the sludge to be treated, reduce the solid content in the sludge to be treated, and get rid of impurities.

[0060] Second: firstly carry out pre-analysis on the impurity-removing sludge, and obtain the initial heavy metal content in the impurity-removing sludge through the pre-analysis, and then calculate the dosage of the chemical reagent according to the above-mentioned initial heavy metal content. Preferably, it is also possible to calculate the initial organic content in the de-trammed sludge.

[0061] Third: put the de-impurity sludge into the reactor, and control the pressure in the reactor to alternately change the high pressure and low pressure to free the heavy metals adsorbed by the microorganisms.

[0062] Fourth: Add chemical reagents to the sludge in the sludge to precipitate heavy metals.

[0063] Fifth: Then, solid-li...

Embodiment 3

[0071] refer to Figure 4 , Figure 5 , The present invention also provides a sludge treatment system, comprising: a sludge pre-treatment unit, a sludge reaction unit and a sludge post-treatment unit. The sludge pre-treatment unit, the sludge reaction unit and the sludge post-treatment unit are connected to form a treatment channel, and chemical reagents for treating heavy metals are arranged in the treatment channel.

[0072] The sludge pre-treatment unit includes a sludge storage tank for storing sludge and a feed pump, the sludge storage tank is provided with a sludge inlet and a sludge outlet, and the feed pump is provided with a feed inlet and supply outlets. The sludge reaction unit includes a reactor and a pressure regulator for alternately changing high pressure and low pressure in the reactor to free the biosorbed heavy metals, and the reactor is provided with a feed inlet, a discharge outlet, and a pressure regulator. Regulating interface, the feed inlet is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com