Gouache and acrylic painting pigment and method for manufacturing same

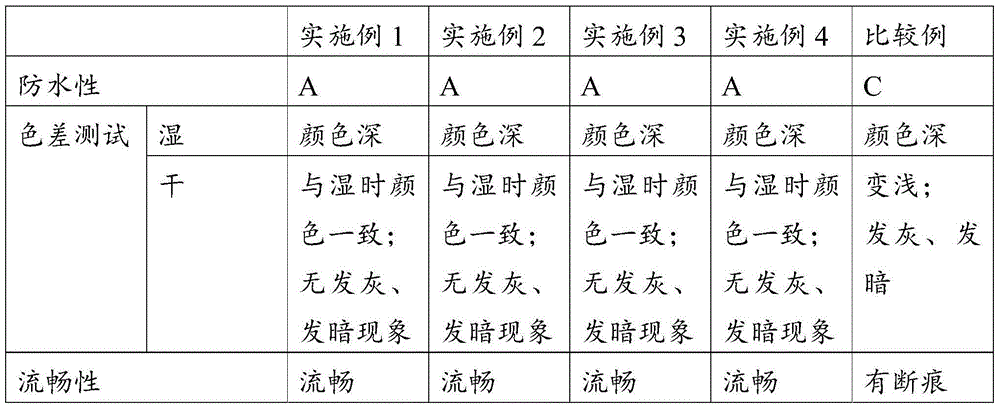

A painting and pigment technology, applied in the field of powder-acrylic paint and its preparation, can solve the problems of uneven painting, large dry-wet color difference, large dry-wet change, etc. The effect of wet chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

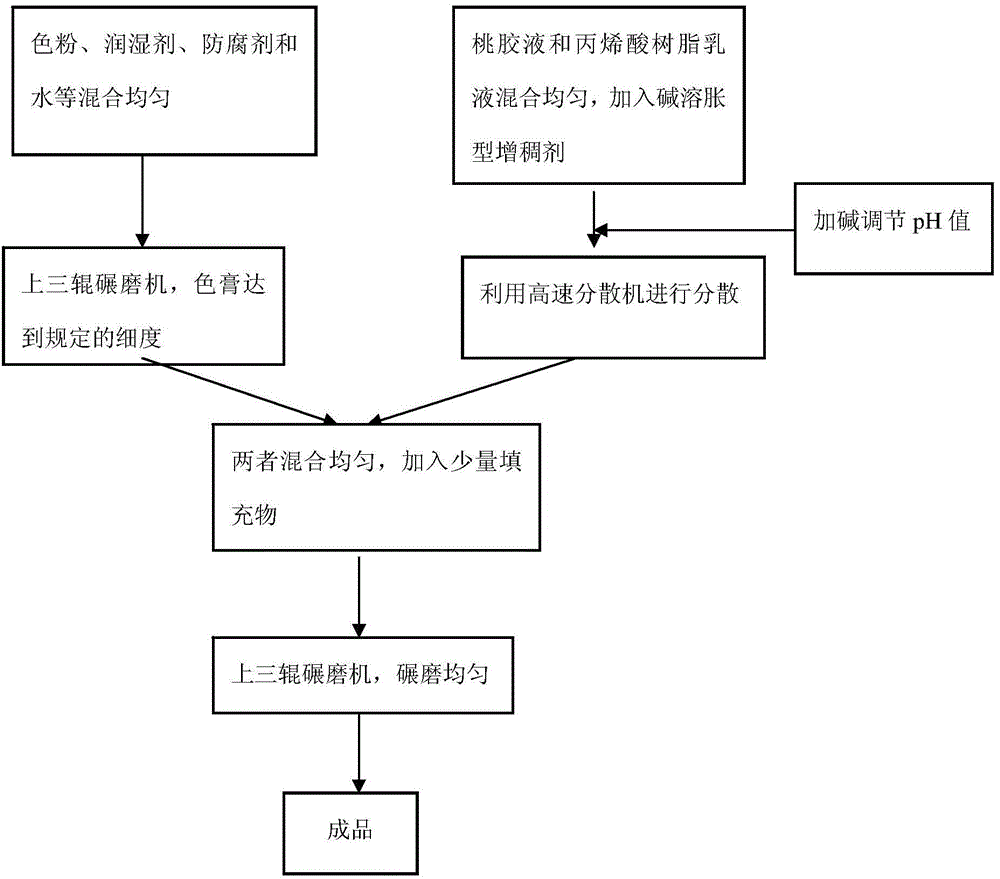

[0050] The invention also discloses a preparation method of powder acrylic paint, comprising the following steps:

[0051] Mix and grind 10-15 parts of toner, 0.3-0.5 parts of wetting agent, 0.02-0.05 parts of preservative and 30-40 parts of water to obtain a color paste;

[0052] After mixing 5-15 parts of peach gum liquid and 25-35 parts of acrylic acid emulsion, add 10-15 parts of alkali-swellable thickener, adjust the pH value to 7-8 with alkali, disperse evenly, and obtain a binder;

[0053] The color paste, binder and 5-10 parts of filler are uniformly mixed to obtain powder acrylic paint.

[0054]In the present invention, toner, wetting agent, preservative, water, peach gum, acrylic acid emulsion, alkali-swellable thickener and filler are used as raw materials. The technical solutions are the same and will not be described again.

[0055] figure 1 Represent the present invention to prepare the schematic flow sheet of powder acrylic paint.

[0056] In the present inv...

Embodiment 1

[0067] Mix 10 parts of toner, 0.3 part of wetting agent, 0.05 part of preservative and 30 parts of water evenly, and grind with a three-roll mill. Get the color paste.

[0068] Heat the peach gum at a constant temperature at 80° C. and continue to stir for 2 hours to form a peach gum solution.

[0069] Mix 5 parts of peach gum and 25 parts of acrylic emulsion, add 10 parts of alkali-swellable thickener, add triethanolamine to adjust the pH value to 7.8, and disperse evenly with a high-speed disperser to obtain an adhesive.

[0070] Mix the obtained color paste and binder evenly, add 5 parts of filler, and grind evenly on a three-roll mill again to obtain powder acrylic paint.

Embodiment 2

[0072] Mix 15 parts of toner, 0.5 part of wetting agent, 0.02 part of preservative and 40 parts of water evenly, and grind with a three-roll mill. Get the color paste.

[0073] Heat the peach gum at a constant temperature at 80° C. and continue to stir for 2 hours to form a peach gum solution.

[0074] Mix 15 parts of peach gum and 35 parts of acrylic emulsion, add 15 parts of alkali-swellable thickener, add triethanolamine to adjust the pH value to 7.5, and disperse evenly with a high-speed disperser to obtain an adhesive.

[0075] Mix the obtained color paste and binder evenly, add 5 parts of filler, and grind evenly on a three-roll mill again to obtain powder acrylic paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com