Modified starch fluid loss additive for drilling fluids and preparation method thereof

A fluid loss control agent, drilling fluid technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of toxic and harmful, comprehensive quality can not effectively meet the requirements of safe drilling, environmental protection, unstable quality, etc. Simple conditions, good promotion and application value, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

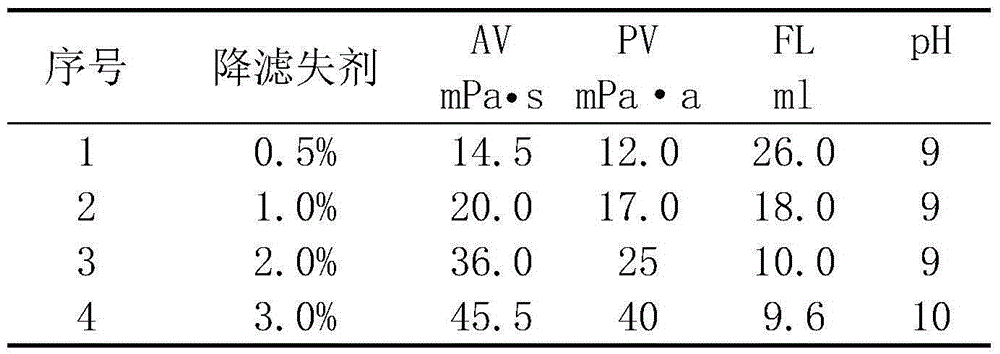

Embodiment 1

[0019] In order to meet the requirements of drilling fluid fluid loss control agents for safe drilling, protection of production layers, and environmental protection in the process of large-scale oilfield development, this embodiment provides a modified starch fluid loss control agent for drilling fluids, which is composed of the following weight percentages: Composition: 60%-80% natural starch, 3%-4% bromoacetic acid, 5%-15% industrial alcohol, 2%-7% sodium hydroxide, 0.1%-0.5% diethylene Triamine, 0.5% to 1.0% glacial acetic acid, the rest is water.

[0020] In addition, the preparation method of the modified starch fluid loss reducer for drilling fluid of the invention comprises the following steps:

[0021] 1) First add 60% to 80% by weight of natural starch into a closed reaction kettle, and start stirring after feeding pure nitrogen for 10 minutes.

[0022] 2) When the temperature of the reaction kettle reaches 50° C. to 80° C., stir and evenly add 3% to 4% bromoacetic ...

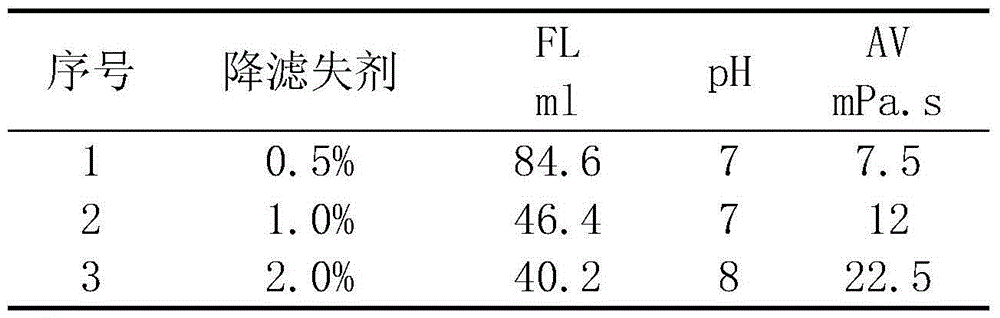

Embodiment 2

[0027] This embodiment provides a modified starch fluid loss reducer for drilling fluid, which is composed of the following components in weight percentage: 80% native starch, 4% bromoacetic acid, 8% industrial alcohol, 3% hydrogenated Sodium, 0.5% diethylenetriamine, 0.5% glacial acetic acid, 4% water; the weight of the bromoacetic acid is 5.0% of the weight of the natural starch.

[0028] The preparation method of the modified starch fluid loss reducer for drilling fluid of the invention comprises the following steps:

[0029] 1) First add 80% by weight of natural starch into a closed reaction kettle, and start stirring after feeding pure nitrogen for 10 minutes.

[0030] 2) When the temperature of the reaction kettle reaches 50° C. to 80° C., stir and evenly add 4% bromoacetic acid and 8% industrial alcohol in sequence to form starch milk.

[0031] 3) Add 3% sodium hydroxide and 0.5% diethylenetriamine successively to the starch milk formed in step 2), stir and react for 6...

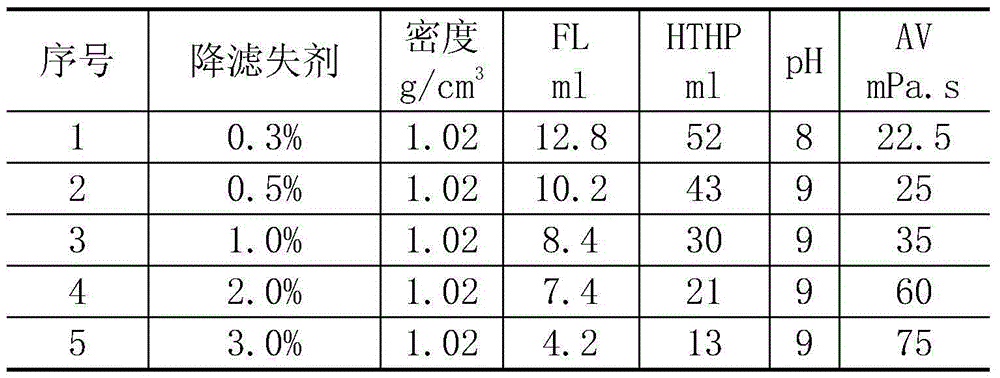

Embodiment 3

[0058] This embodiment provides a modified starch fluid loss reducer for drilling fluid, which is composed of the following components in weight percentage: 60% native starch, 3% bromoacetic acid, 15% industrial alcohol, 2% hydrogenated Sodium, 0.1% diethylenetriamine, 0.8% glacial acetic acid, 19.1% water. First add 60% natural starch by weight into the closed reaction kettle, and start stirring after 10 minutes of feeding pure nitrogen; when the temperature of the reaction kettle reaches 50°C to 80°C, stir and slowly and evenly add 3% bromoacetic acid, 15% industrial alcohol forms starch milk; then add 2% sodium hydroxide to alkalize, then add 0.1% diethylenetriamine (completely added in 30 minutes), stir and react for 60 minutes, stop heating; finally, add 0.8% glacial acetic acid and 19.1% water, adjust the pH value to 7-9, cool, then dry the cooled components at 100°C-120°C, pulverize, and obtain the modified drilling fluid Starch fluid loss control agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com