An air duct for copper wire water treatment

A water treatment and air duct technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of copper wire surface finish and shelf life, and achieve the effects of fast speed, good cleaning effect, and avoiding severe impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

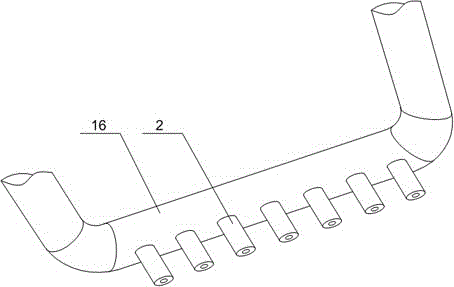

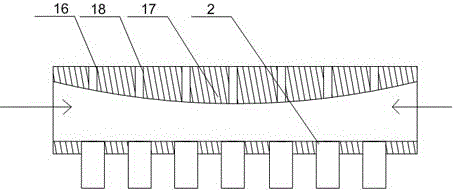

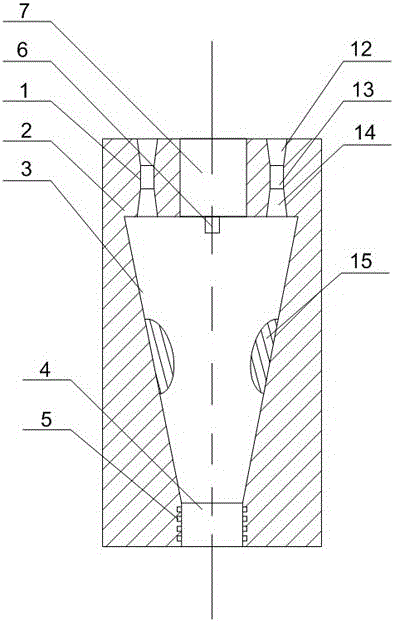

[0023] Such as Figure 1 ~ Figure 4 As shown, this embodiment includes an air duct 16 and a plurality of air nozzles 2 arranged side by side on the air duct 16, and a protrusion with a circular arc-shaped cross section is provided on the inner wall of the air duct 16 on the opposite side from the air nozzle 2 17, and a plurality of wire passing holes 18 are opened on the air duct 16 on the same side of the protrusion 17. The apex of the protrusion 17 is located on the vertical line of the horizontal part of the air duct 16. There are two air inlet holes 1 and air outlet holes 4 corresponding to the wire passing holes 18. Inside the nozzle body 2, there is a conical wind collecting cavity 3 with an inner diameter decreasing along the wind direction. The middle part of the air inlet hole 1 is rotated with an adjustment ring 7, and the adjustment ring 7 is coaxial with the wind gathering cavity 3 and the air outlet hole 4, and a spiral protrusion 5 is fixed on the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com