Cotton and natural silk napped fabric and method for processing same

A processing method, Tencel technology, applied in fabric surface trimming, textile material treatment, textile material continuous treatment, etc., can solve problems such as high moisture regain, poor warmth retention, and poor velvet feel uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

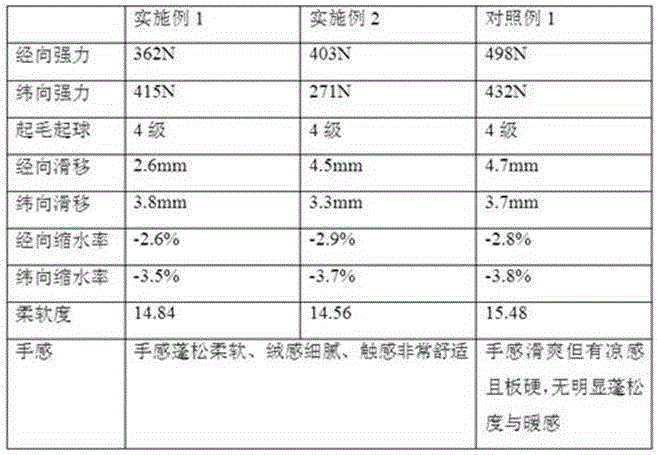

Embodiment 1

[0031]Specifications: 106' / 80s*80s / 200*196, the warp and weft yarns are made of 80s ring-spun long-staple cotton and fine-denier Tencel G100 blended yarn, and the blending ratio is 80% long-staple cotton and 20% fine-denier Tencel G100 fiber , 5 pieces of 3 flying warp satin weave.

[0032] The production method includes the following steps: blended yarn → winding → warping → sizing → reeding → weaving → gray fabric singeing → desizing, scouring, bleaching → mercerizing → carbon sanding → printing → steaming Washing → soft shaping → pre-shrinking.

[0033] Sizing process: 50kg of phosphate starch, 75kg of CD-DF868 high-performance starch, 5kg of propylene and 3kg of wax flakes.

[0034] The singeing process adopts one front and one reverse, the speed of the vehicle is 120m / min, the fire is extinguished by rolling enzyme, the amylase is 6g / L, the cloth is dropped by the car, and the pile is 6h.

[0035] The descouring and bleaching process adopts the one-bath method of boilin...

Embodiment 2

[0040] Specifications: 106' / 60s*60s / 200*100, the warp is made of 60s compact spun long-staple cotton and fine-denier Tencel G100 blended yarn, the blending ratio is 80% long-staple cotton, 20% fine-denier Tencel G100 fiber, weft yarn 60s siro-spun long-staple cotton and fine-denier Tencel G100 blended yarn are used. The blending ratio is 70% long-staple cotton, fine-denier Tencel G100 fiber 30%, and satin weave of 5 pieces and 2 flying warps.

[0041] The production method includes the following steps: blended yarn → winding → warping → sizing → reeding → weaving → gray fabric singeing → desizing, scouring, bleaching → mercerizing → carbon sanding → printing → steaming Washing → soft shaping → pre-shrinking.

[0042] Sizing process: phosphate ester starch slurry 75kg, CD-DF868 high-performance starch slurry 50kg, propylene 4kg and wax flake 3kg.

[0043] The singeing process adopts one front and one reverse, the speed of the machine is 110m / min, the fire is extinguished by ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com