Smoothing agent for fabrics and preparation method thereof

A technology for a smoothing agent and fabric, applied in the field of a smoothing agent for fabrics and its preparation, can solve the problems of high use environment requirements, easy to fall off, poor stability of the smoothing agent, etc., and achieves easy industrial production, simple preparation method, safe and environmentally friendly raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

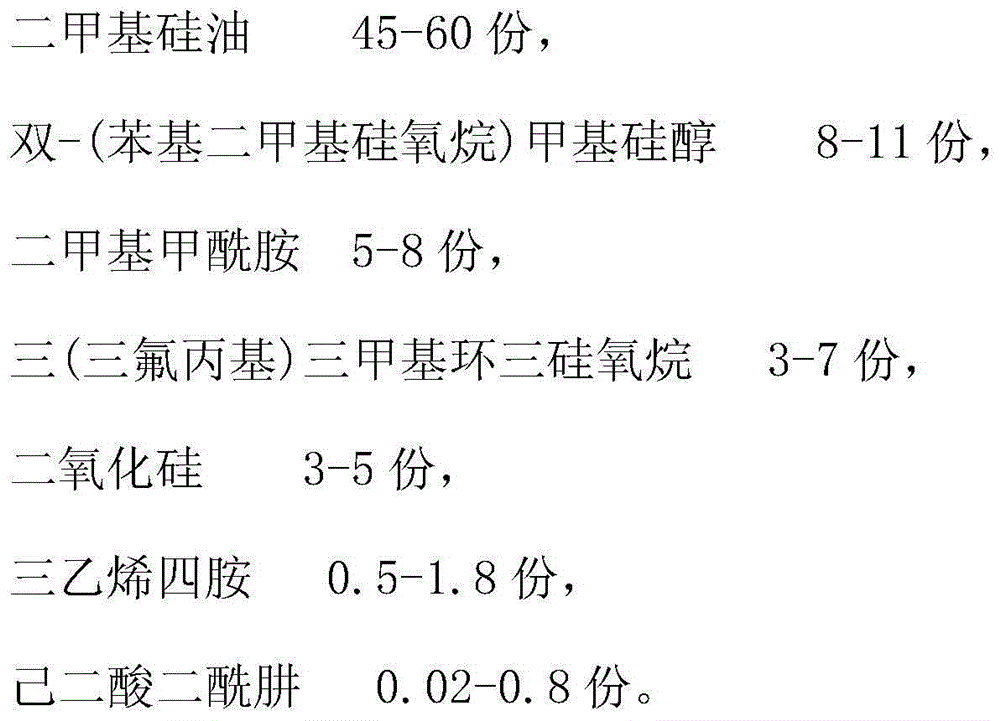

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 60kg of simethicone oil, 5kg of dimethylformamide, 3kg of silicon dioxide with a diameter of 18 nanometers and 0.5kg of triethylenetetramine, mix well, add bis-(phenyldimethylsiloxane ) methylsilanol 8kg, three (trifluoropropyl) trimethylcyclotrisiloxane 3kg, mix 8 minutes in high-speed shearing machine;

[0024] (2) Slowly add the mixture of 2-heptadecyl imidazole 1.2kg, sodium pyrophosphate 0.5kg and adipic acid dihydrazide 0.02kg under the stirring condition of 1800 rpm in a high-speed mixer at 55°C, The temperature was kept at 50° C. for 3 hours to obtain a smoothing agent for fabrics.

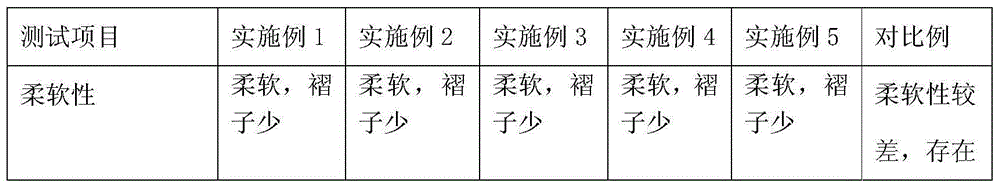

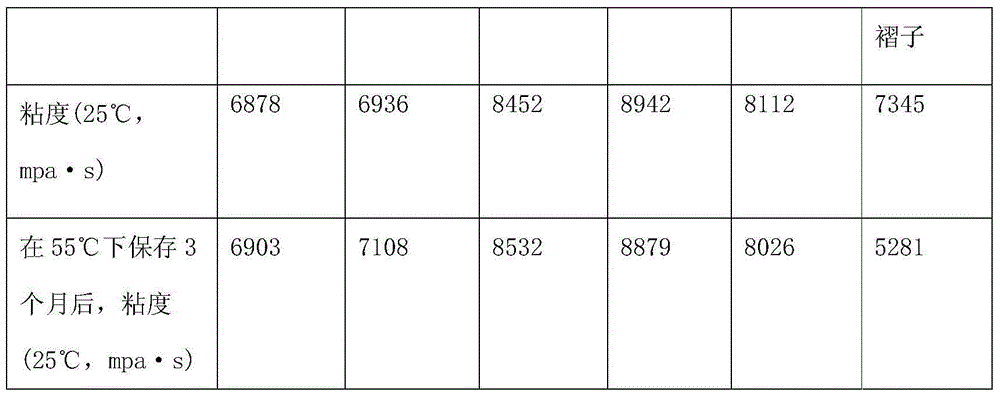

[0025] The performance test results of the smoothing agent for fabrics are shown in Table 1.

Embodiment 2

[0027] (1) Weigh 60kg of simethicone oil, 8kg of dimethylformamide, 3kg of silicon dioxide with a diameter of 18 nanometers and 0.5kg of triethylenetetramine, mix well, add bis-(phenyldimethylsiloxane ) methylsilanol 11kg, three (trifluoropropyl) trimethylcyclotrisiloxane 3kg, mixed in a high-speed shear for 8 minutes;

[0028] (2) Slowly add the mixture of 2-heptadecyl imidazole 1.2kg, sodium pyrophosphate 0.5kg and adipic acid dihydrazide 0.02kg under the stirring condition of 1800 rpm in a high-speed mixer at 55°C, The temperature was kept at 50° C. for 3 hours to obtain a smoothing agent for fabrics.

[0029] The performance test results of the smoothing agent for fabrics are shown in Table 1.

Embodiment 3

[0031] (1) Weigh 45kg of simethicone oil, 5kg of dimethylformamide, 5kg of silicon dioxide with a diameter of 45 nanometers and 1.8kg of triethylenetetramine, mix well, add bis-(phenyldimethylsiloxane ) methylsilanol 8kg, three (trifluoropropyl) trimethylcyclotrisiloxane 3kg, mix 8 minutes in high-speed shearing machine;

[0032] (2) at 75 DEG C, slowly add the mixture of 2-heptadecyl imidazole 1.2kg, sodium pyrophosphate 0.5kg and adipic acid dihydrazide 0.8kg under the stirring condition of 2500 rpm in a high-speed mixer, The temperature was kept at 70° C. for 1.5 hours to obtain a smoothing agent for fabrics.

[0033] The performance test results of the smoothing agent for fabrics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com