Heating and stirring tank for comprehensive pavement maintenance

A technology for heating and stirring tanks, applied in the field of heating and mixing tanks, which can solve the problems of asphalt mixture pollution, insufficient heat utilization, and large volume, and achieve the effects of reducing heat loss, facilitating on-board maintenance, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

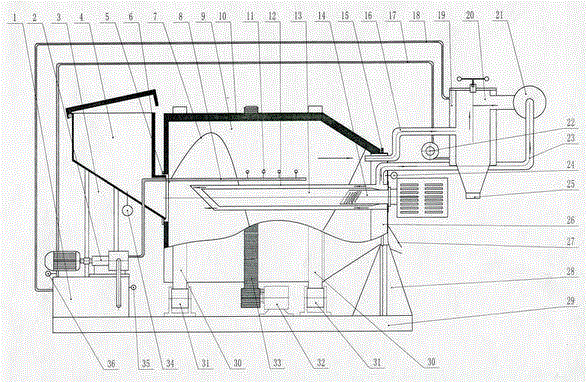

[0008] The embodiment is described in detail in conjunction with the above accompanying drawings. This technical solution is composed of a mixing tank 9, a feeding box 4, a discharge box 25, a hot air combustion chamber 13, a dust collector 20, an asphalt tank 1 and other executive components. The outside is wrapped with an insulating layer 10, and the mixing tank 9 is supported by a tank support ring 30. The power on the mixing tank is driven by a drive ring gear 33 through a reducer 32. The inside of the mixing tank is provided with a spiral blade 7. Further: a support ring 30 Fix by small support ring 31 and chassis frame 29 again, one end of mixing tank is provided with charging box 4, and its other end is discharge box 25, and charging box temperature sensor 34 is installed on the described charging box, on charging box and stirring tank The feed inlet is connected by feed flange 5, and the connection method can be welding. The gap between the feed flange and the feed inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com