Flexible shroud material for commercial vehicle engine

A technology of engine and wind protection ring, which is applied in the field of engine cooling, can solve the problems of poor heat resistance and aging resistance, difficult maintenance and replacement, and high failure rate, so as to improve anti-aging performance and heat resistance, reduce costs and Effect of vehicle weight, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

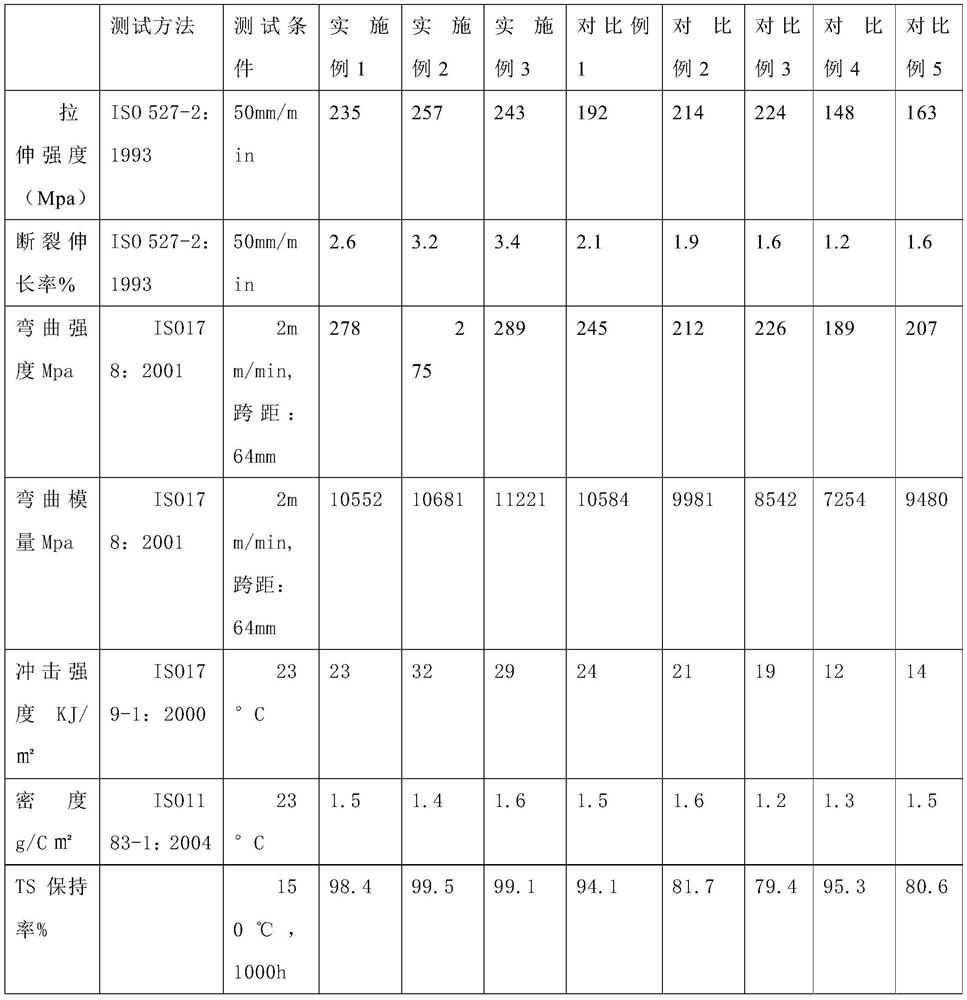

Examples

Embodiment 1

[0026] A flexible windshield material for a commercial vehicle engine, wherein: by weight, it includes the following materials: 50 parts of nylon, 40 parts of glass fiber, 1 part of compatibilizer, 1 part of lubricant, 1 part of stabilizer, Ti 3 SiC 2 2 parts, 3 parts of polylactide fiber filaments, 0.2 parts of octyl acrylate-butadiene copolymer.

[0027] The compatibilizer is polyvinylidene fluoride, the lubricant includes 35% pentaerythritol stearate and 65wt% polyoxanorbornene; the stabilizer is composed of the following components by mass: tetrafluoropropanol 20wt%, pyrithione Zinc 35wt%, N,N-1,6-hexylidene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide 45wt%, octyl acrylate-butadiene copolymer The number average molecular weight is 3200g / mol, Ti 3 SiC 2 The particle size is 60nm.

[0028] A preparation method of a flexible windshield material for a commercial vehicle engine, comprising the following steps:

[0029] S1. Weigh nylon, compatibilizer, lubricant,...

Embodiment 2

[0032] A flexible wind protection ring material for a commercial vehicle engine, characterized in that: by weight, it includes the following materials: 80 parts of nylon, 45 parts of glass fiber, 3 parts of compatibilizer, 5 parts of lubricant, 4 parts of stabilizer, Ti 3 SiC 2 3 parts, 4 parts of polylactide fiber, 1 part of octyl acrylate-butadiene copolymer,

[0033] The compatibilizer is polypropylene grafted maleic anhydride, the lubricant includes 36% pentaerythritol stearate and 64wt% polyoxanorbornene, and the stabilizer consists of the following components by mass: tetrafluoropropanol 25wt%, Zinc pyrithione 40wt%, N,N-1,6-hexylene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide 35wt%; octyl acrylate-butylene The number average molecular weight of ene copolymer is 3300g / mol, Ti 3 SiC 2 The particle size is 80nm.

[0034] A preparation method of a flexible windshield material for a commercial vehicle engine, comprising the following steps:

[0035]S1. Weigh ...

Embodiment 3

[0038] A flexible windshield material for a commercial vehicle engine, wherein: in parts by weight, the following materials are included: 100 parts of nylon, 50 parts of glass fiber, 5 parts of compatibilizer, 10 parts of lubricant, 10 parts of stabilizer, Ti 3 SiC 2 4 parts, 7 parts of polylactide fiber filaments, 2 parts of octyl acrylate-butadiene copolymer.

[0039] The compatibilizer is epoxy resin grafted polyacrylate latex; the lubricant includes 40% pentaerythritol stearate and 60wt% polyoxanorbornene, and the stabilizer consists of the following components by mass: tetrafluoropropanol 30wt% , zinc pyrithione 45wt%, N,N-1,6-hexylidene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide 25wt%; octyl acrylate-butyl The number average molecular weight of diene copolymer is 3400g / mol, Ti 3 SiC 2 The particle size is 100nm.

[0040] A preparation method of a flexible windshield material for a commercial vehicle engine, comprising the following steps:

[0041] S1. We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com