Method for processing spicy fresh clams

A processing method and a technology for spicy fresh clams, which are applied in the processing field of spicy fresh clams, can solve the problems of nutrient loss, poor taste of clam meat, single taste, etc., and achieve the effects of convenient eating, avoiding the reproduction of pathogens, and having a unique flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

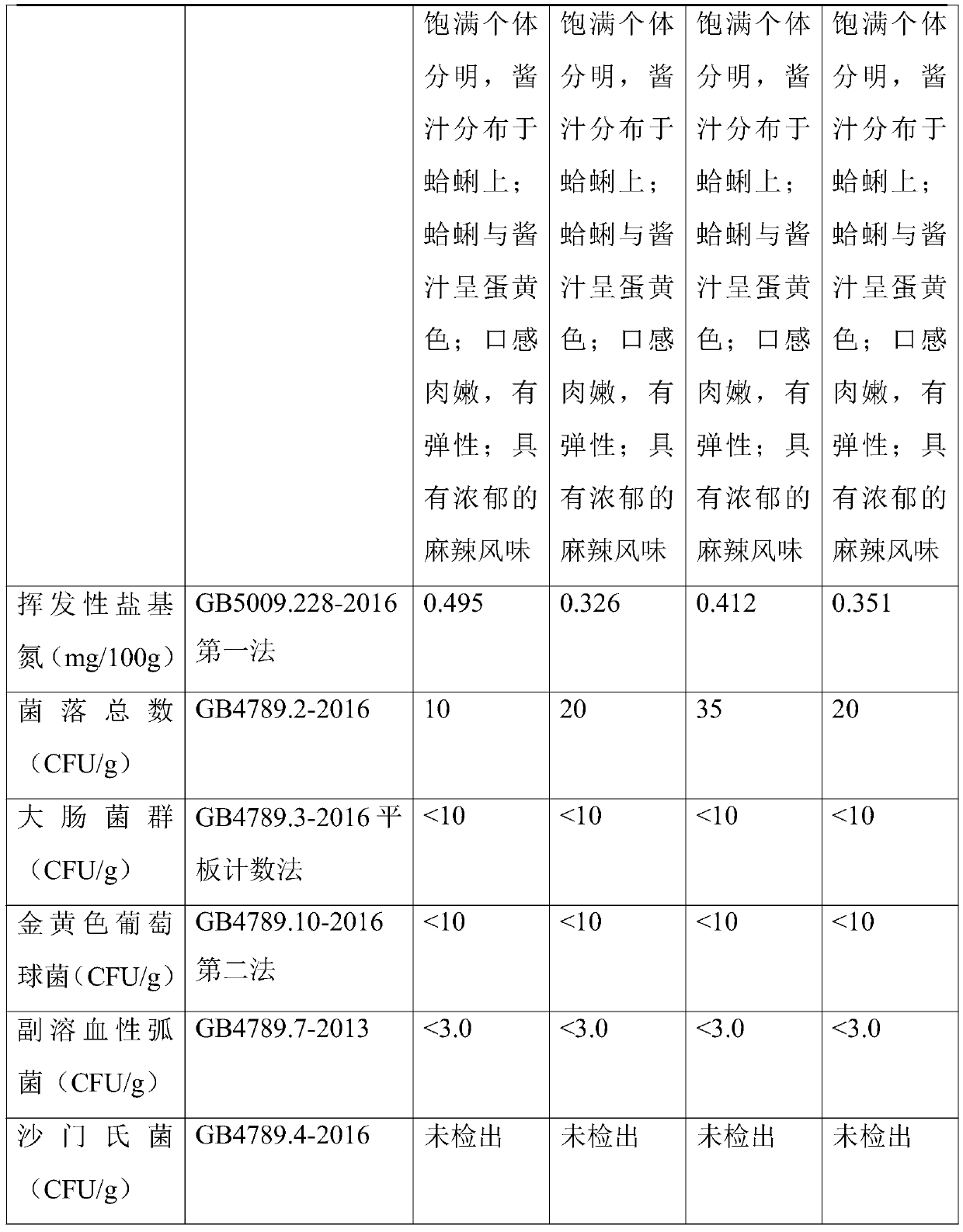

Embodiment 1

[0041] A processing method of spicy fresh clams, comprising the following steps:

[0042] (1) Raw material thawing: put the frozen cooked clam meat into the thawing tank, and use tap water (in line with the standard of drinking water) to thaw. During the thawing process, the water temperature is below 4°C, and the thawing time is about 4 hours. During the thawing process, keep the ice-water mixture state. When the center temperature of clam raw material is at 0~-2℃; thawing ends.

[0043] (2) Selection / cleaning: After thawing, select the raw materials, pick out the possible impurities, and wash them with water < 4°C after picking. After cleaning, put them into the feeding cart and send them to the pickling workshop to wait system.

[0044] (3) Pickling: Add the marinade, stir and mix well, and then marinate for 20 hours in an environment with a temperature <4°C, as follows:

[0045] (3.1) Weigh 25% of water, and pour it into a stainless steel trough when the water temperatur...

Embodiment 2

[0066] A processing method of spicy fresh clams, comprising the following steps:

[0067] (1) Raw material thawing: put the frozen cooked clam meat into the thawing tank, and use tap water (in line with the drinking water standard) to thaw. During the thawing process, the water temperature is below 4°C, and the thawing time is about 3 hours. During the thawing process, the ice-water mixture should be kept. When the center temperature of clam raw material is at 0~-2℃; thawing ends.

[0068] (2) Selection / cleaning: After thawing, select the raw materials, pick out the possible impurities, and wash them with water < 4°C after picking. system.

[0069] (3) Pickling: add marinade, stir and mix well, and then marinate for 18 hours in an environment with a temperature <4°C, as follows:

[0070] (3.1) Weigh 23% of water, and pour it into a stainless steel trough when the water temperature is less than 4°C;

[0071] (3.2) Weigh 20% fructose syrup, pour it into a stainless steel trou...

Embodiment 3

[0091] A processing method of spicy fresh clams, comprising the following steps:

[0092] (1) Raw material thawing: put the frozen cooked clam meat into the thawing tank, and use tap water (in line with the standard of drinking water) to thaw. During the thawing process, the water temperature is below 4°C, and the thawing time is about 5 hours. During the thawing process, keep the ice-water mixture state. When the center temperature of clam raw material is at 0~-2℃; thawing ends.

[0093] (2) Selection / cleaning: After thawing, select the raw materials, pick out the possible impurities, and wash them with water < 4°C after picking. system.

[0094] (3) Marinate: Add marinade, stir and mix well, and marinate for 24 hours in an environment with a temperature <4°C, as follows:

[0095] (3.1) Weigh 28% of water, water temperature < 4°C, pour it into a stainless steel trough;

[0096] (3.2) Weigh 21% fructose syrup, pour it into a stainless steel trough, and stir evenly with wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com