A prefabricated house and its construction method

A technology of prefabricated assembly and construction method, which is applied in the direction of structural elements, building components, and elongated structural components for load-bearing, etc. problem, to achieve the effect of good stress state, light structure, improved rigidity and axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

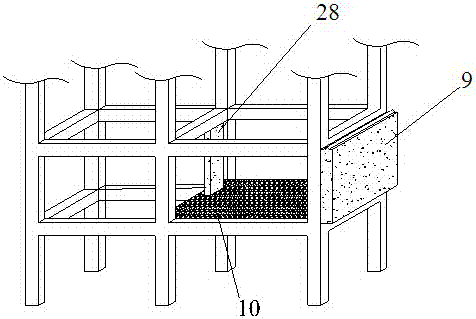

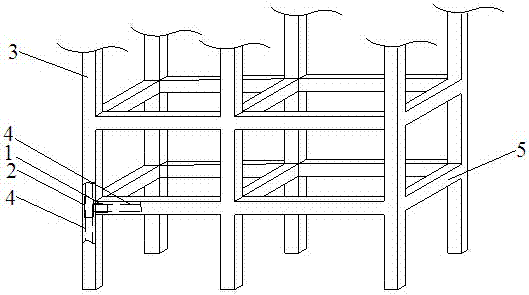

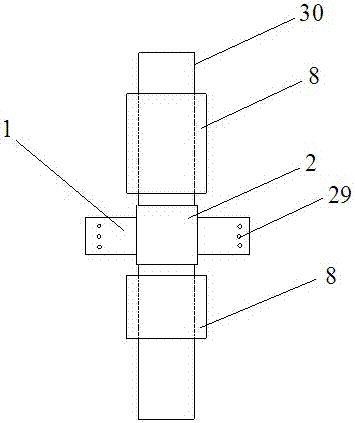

[0054] refer to figure 1 , figure 2 , this embodiment includes a house foundation, in which a foundation connector is pre-embedded, and a vertical prefabricated column is arranged on the foundation connector; refer to image 3 , Figure 4 , the prefabricated column 3 includes a prefabricated column rectangular steel pipe 30, the prefabricated column rectangular steel pipe 30 is filled with reactive powder concrete 7, except for the two ends of the prefabricated column rectangular steel pipe 30, the outside of the prefabricated column rectangular steel pipe 30 is wrapped with foamed cement 8; The prefabricated columns 3 are arranged vertically and horizontally, and the prefabricated columns 3 in the same vertical direction are superimposed one after another. Horizontal prefabricated beams 5 are installed between the tops of the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com