Magnetic fluid lubricating method

A magnetic fluid and magnetic field technology, applied in the direction of engine lubrication, bearings, engine components, etc., can solve the problems of low volatilization, long life, high saturated vapor pressure, and narrow operating temperature range that are difficult to meet, and achieve the elimination of volatilization loss, Slow down the loss and enhance the effect of adsorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

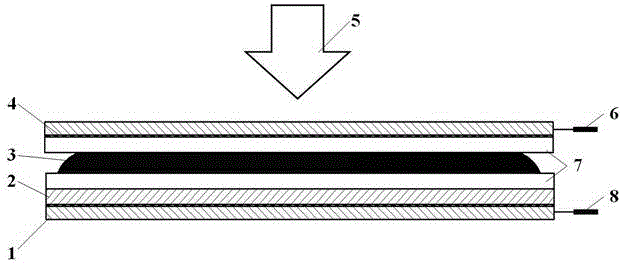

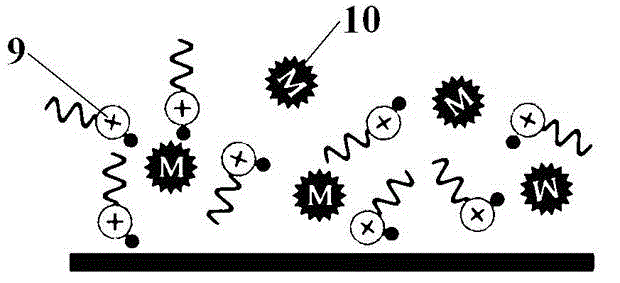

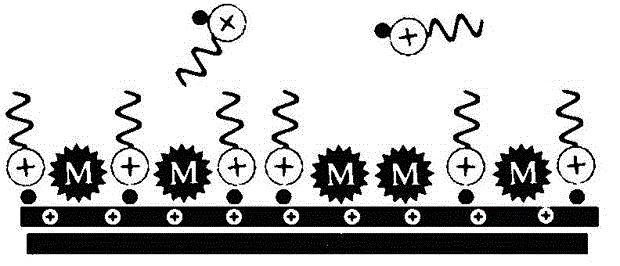

[0027] The invention discloses a magnetic fluid lubrication method, which fully utilizes the zero volatilization of the ionic liquid-based magnetic fluid and the adsorption effect under the electromagnetic field, and specifically includes the following steps:

[0028] In step 1), the ionic liquid is used as the base carrier liquid to prepare the ionic liquid-based ferrofluid.

[0029] A typical ionic liquid series (such as imidazole ionic liquid) with excellent stability (such as wide temperature range, anti-oxidation, corrosion resistance) and lubricating properties is selected as the base carrier liquid to prepare a stable ionic liquid-based magnetic fluid.

[0030] Step 2), disposing the ionic liquid-based magnetic fluid on the surface of the friction pair.

[0031] The surface material of friction pair can choose ferromagnetic material and non-ferromagnetic material. Ferromagnetic materials include electrical pure iron and ordinary carbon steel. Electrical pure iron is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com