Manufacturing process of special polyethylene lined oil pipe

A manufacturing process, polyethylene technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of unreasonable processes, poor anti-eccentric wear and anti-corrosion performance of polyethylene-lined oil pipes, and short working life, etc. Reasonable process, better corrosion resistance and anti-eccentric wear performance, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

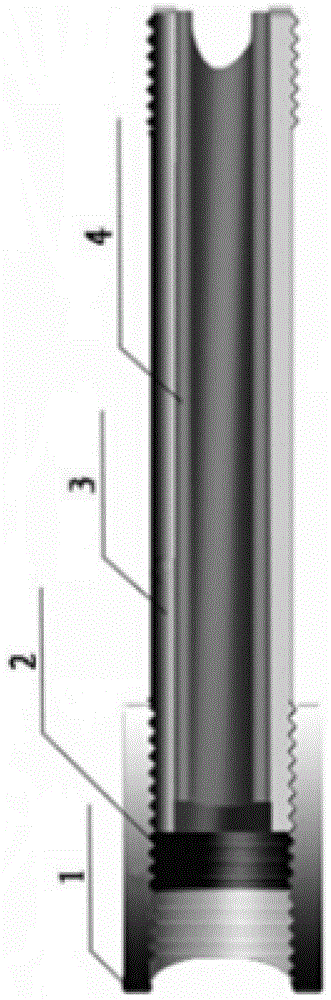

[0008]A manufacturing process for special polyethylene-lined oil pipes, A. The modified ultra-high molecular weight polyethylene is formed through a composite co-extrusion screw extruder (ZL200510105781.1) to form a length greater than 3 lengths of each oil pipe and pass through ( Inner diameter of 62.0mm) oil pipe 3 lumen can be fixed with the polyethylene liner 4 of the oil pipe 3, and then perform disassembly of the non-partial wear and anti-corrosion complete set of oil well connecting pipe assembly in the non-use state Solution, cleaning and anti-corrosion process of the non-working parts of the inner thread of the pipe collar. The complete set of oil well connecting pipe components includes the inner thread and the outer thread of one end of the oil pipe 3. The outer thread is fixed and set on the outer wall of the oil pipe 3. The protective cover and the outer thread have been connected with the inner thread at one end of the pipe collar 1, and the inner thread protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com