Normal-temperature pneumatic drying equipment

A kind of airflow drying and equipment technology, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc. It can solve the problems of large loss of volatile components, failure to maintain the shape of materials, and failure to inhibit material oxidation, etc., to achieve accelerated drying Speed, Oxidation Inhibition, Reduced Loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A kind of example of molecular sieve drier

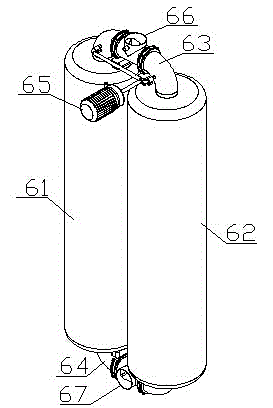

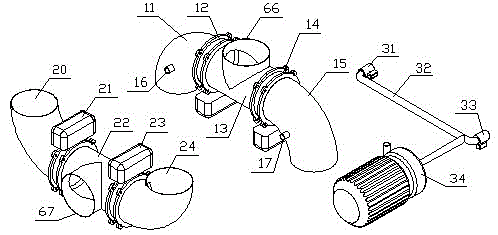

[0018] see figure 1 , figure 2, a circulating fluidized bed air inlet gas treatment device, composed of 1# molecular sieve container 61, 2# molecular sieve container 62, air inlet pipeline 63, air outlet pipeline 64 and regeneration branch 65; 1# molecular sieve container 61 One end is provided with an air inlet, and the other end is provided with an air outlet. The 1# molecular sieve container 61 is equipped with a molecular sieve, and the 2# molecular sieve container 62 has the same structure as the 1# molecular sieve container 61; , 1# branch pipe 11, 2# valve 14, and 2# branch pipe 15. The first port of the three-way I13 is the air inlet 66 of this example, and the second port of the three-way I13 is connected to the inlet of the 1# valve 12. , the outlet of 1# valve 12 is connected with the inlet of 1# branch pipe 11, the third port of tee I13 is connected with the inlet of 2# valve 14, the outlet of 2# ...

Embodiment 2

[0020] Embodiment 2: A kind of normal temperature air flow drying equipment

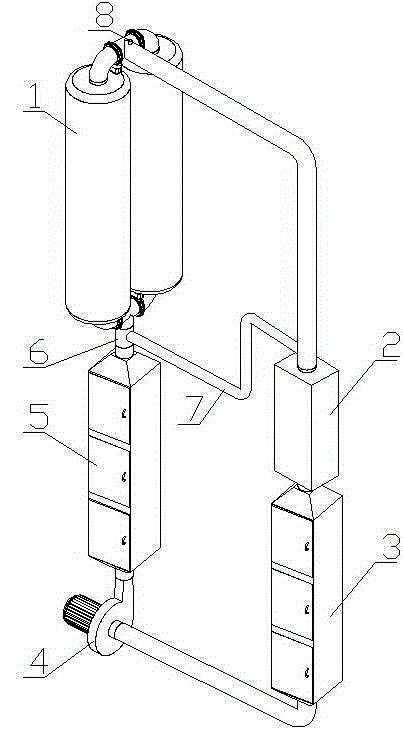

[0021] see image 3 , a normal temperature airflow drying equipment, composed of a molecular sieve dryer 1, an air heater 2, a storage rack 3, a fan 4, a storage rack 5, an air duct 6, and a pipeline 7, the molecular sieve dryer 1 and the molecular sieve drying described in Example 1 The air outlet of the molecular sieve dryer 1 is also provided with a gas supply interface 8, the gas supply interface 8 is connected to the inert gas source, the temperature of the hot air output by the air heater 2 is below 50 ° C, and the shelf 3 and the shelf 5 The structure is the same, all are closed boxes with doors, and the interior is layered with grids. The materials are evenly placed on the grids, and there are gaps between the materials and the sum of any cross-sectional area of the gap is greater than the cross-sectional area of the air outlet of fan 4. , a mesh cover with self-tensioning function is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com