Preparation method of transmission electron microscopic sample

An electron microscope and sample technology, applied in the preparation of test samples, etc., can solve the problems of easily causing undercuts, blurred images, waste of time, etc., and achieve the effect of shortening preparation time, avoiding blurring of images, and avoiding drifting of images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0049] refer to Figure 7 , the TEM sample preparation method of the present embodiment comprises the following steps:

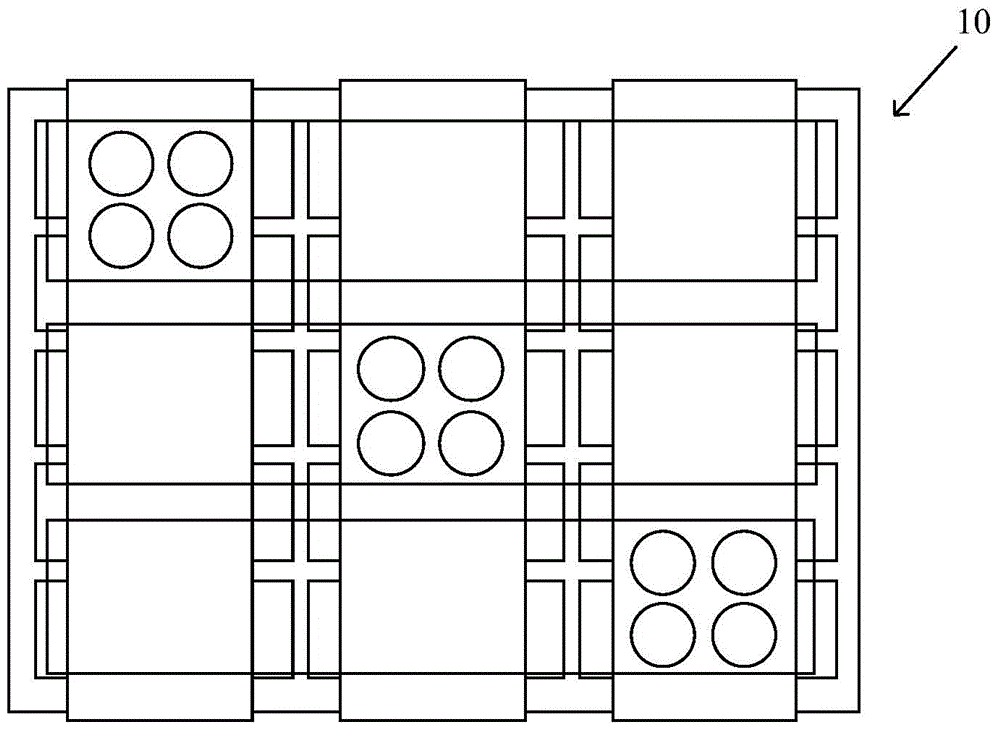

[0050] Step S21, providing a sample with length, width and thickness, the sample has an observation target, and the observation target includes at least one elongated structure or multi-layer stacked structure along the thickness direction;

[0051] Step S22, mark the surface of the sample defined by the length and width directions, and the distance between the mark and the observation target is within a preset distance range;

[0052] Step S23, grinding the sample to the mark along a direction perpendicular to the thickness direction;

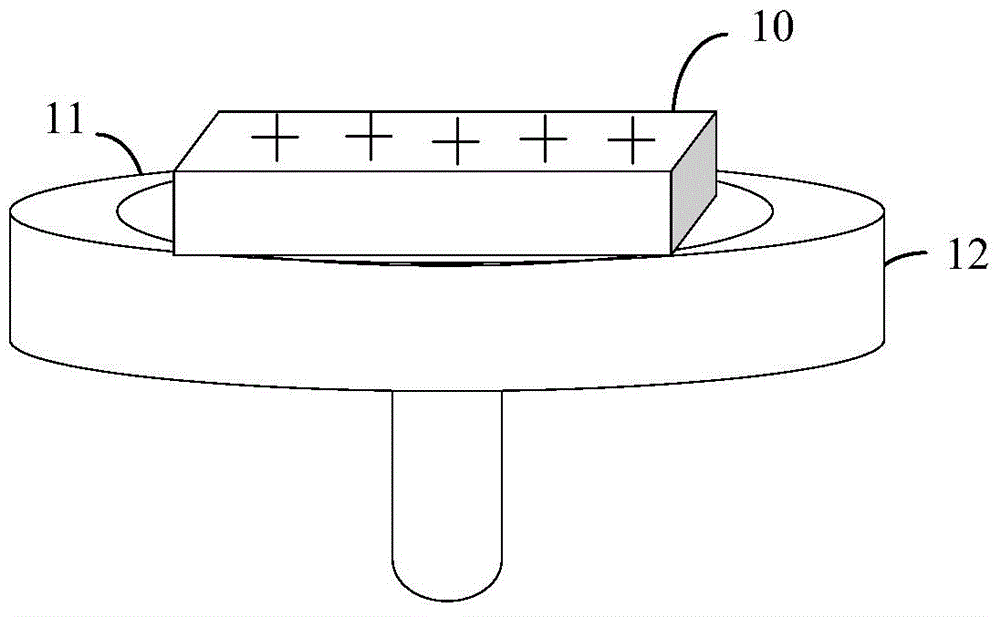

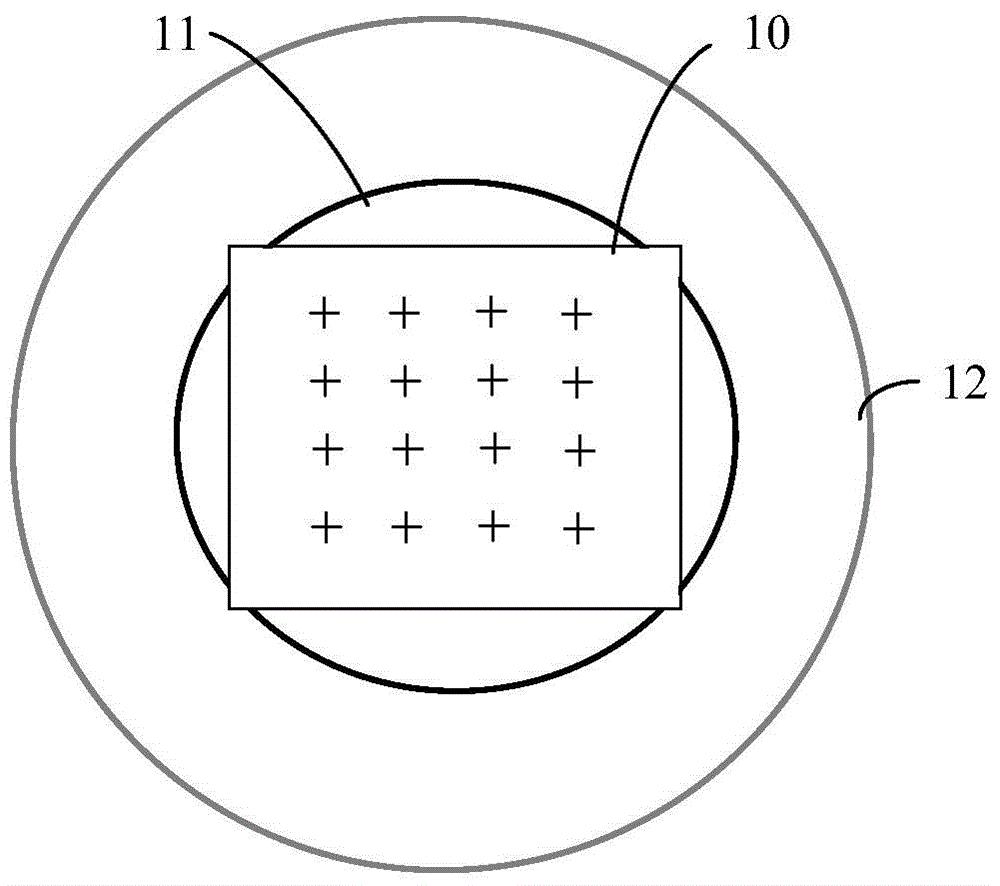

[0053] Step S24, placing the sample on the carrier platform, the grinding surface of the sample is away from the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com