Pretreatment device for extracting cellulose and hemicellulose from crop straw to produce ethanol

A technology of crop straw and pretreatment device, which is applied in the directions of biomass pretreatment, biomass post-treatment, and biochemical cleaning devices, etc., can solve the problems such as sagging deformation of the stirring shaft, serious sticking to the wall and bottoming, and easy sagging deformation. , to achieve smooth and uniform material tumbling, optimize pretreatment efficiency, and enhance the effect of pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

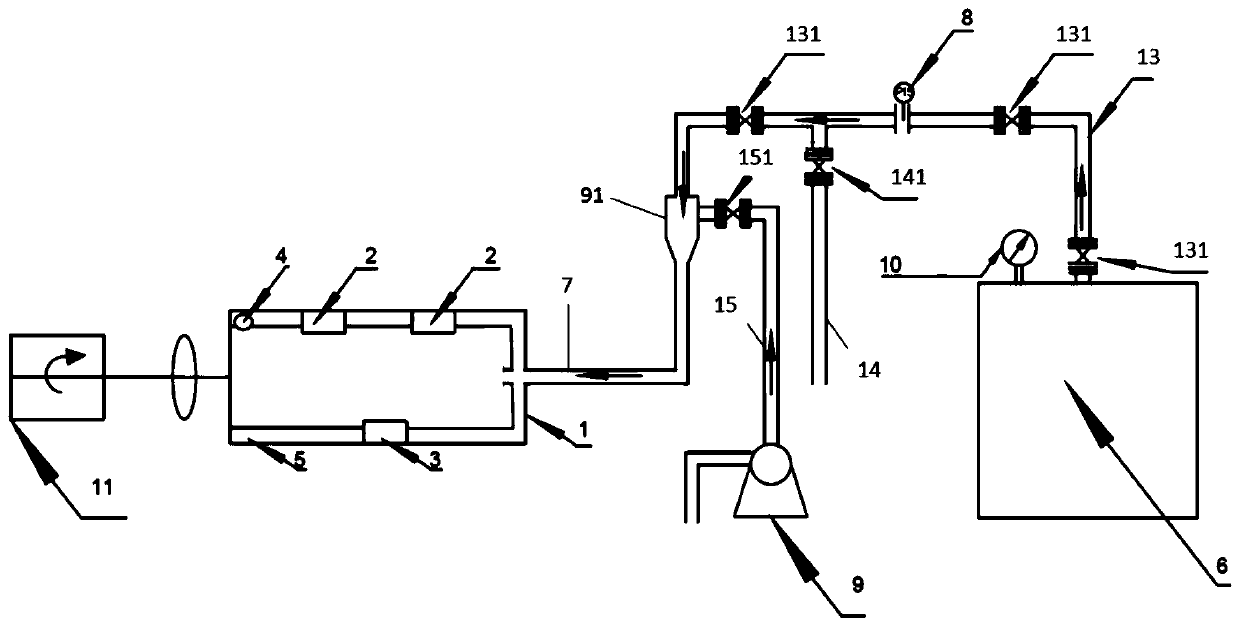

[0030] Such as Figure 1-2 As shown, a pretreatment device for extracting cellulose and hemicellulose from crop stalks to produce ethanol includes a horizontal pretreatment tank 1, a steam generator 6, a feed pump 9 and a mixer 91, the steam generator 6 and the feeder The material pump 9 is connected in parallel with a mixer 91 , and the mixer 91 is connected with the horizontal pretreatment tank 1 . Mixer 91 is a Venturi mixer

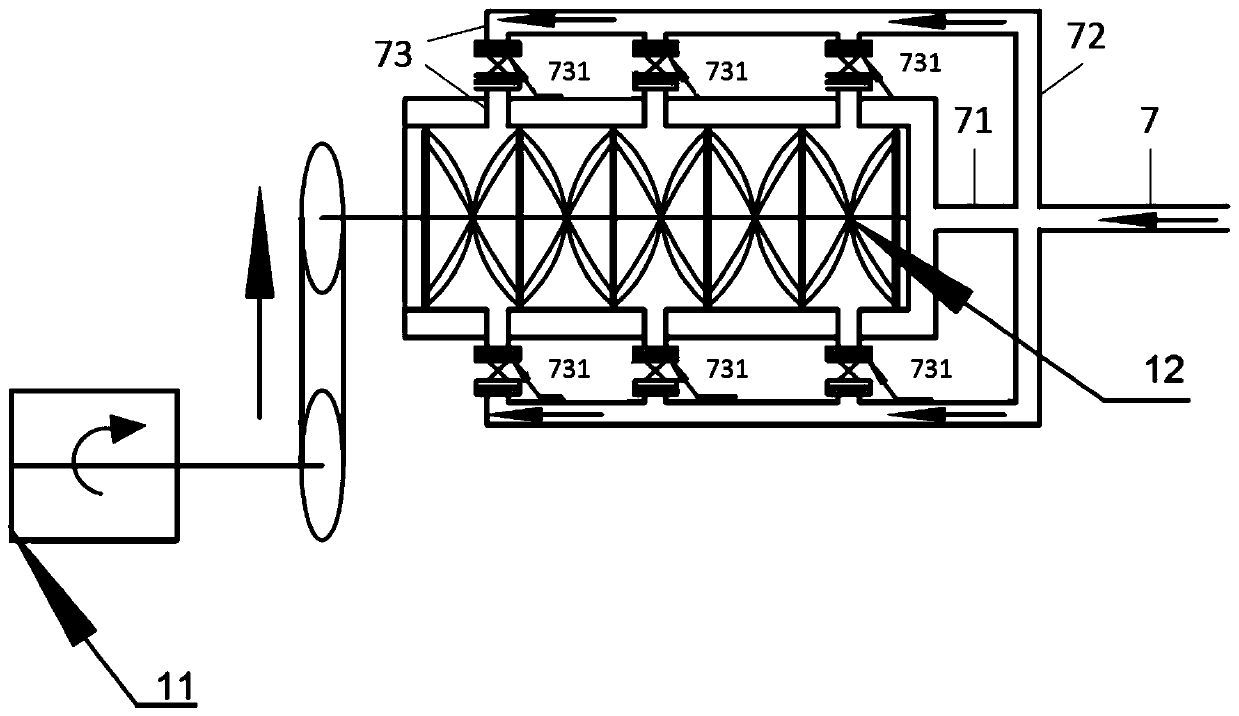

[0031] The horizontal pretreatment tank 1 includes an internal stirring paddle 12 and a temperature sensor, an upper feed port 2, a lower discharge port 3, a side mirror 4 and an external jacket 5, and the stirring paddle 12 is connected to an external motor 11. And carry out forward rotation, reverse rotation and both alternate rotations according to time.

[0032] The A pipeline 7 connecting the mixer 91 to the horizontal pretreatment tank 1 includes the a branch pipe 71 connected to the jacket 5, and the b branch pipe 72 extending to both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com