Rapid quality evaluation method for urea reducing agent used by SCR tail gas post processing apparatus

A technology for post-treatment of exhaust gas and reducing agent, which is applied in the measurement of phase influence characteristics, color/spectral characteristics, material resistance, etc., which can solve the problem that the test cost and feedback speed are not suitable for end-user urea reducing agent quality evaluation and urea reducing agent samples. It does not have problems such as operability and long detection period, so as to save maintenance time and claim costs, and achieve intuitive results and low costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take a urea reducing agent solution with a turbid and opaque appearance, but without visible floating and suspended turbid impurities, use the method in step 1 of the quick test method, and if it does not meet the above appearance requirements through visual inspection, it can be evaluated on-site as impurity content exceeding the standard. It can be judged as unqualified product. In fact, according to the national standard GB29518-2013 diesel engine nitrogen oxide reducing agent urea aqueous solution (AMS32), the water insoluble matter test is carried out, and the water insoluble matter is 107.5 mg / kg (the national standard requires that this item is not more than 20 mg / kg), rapid determination method and standard determination The results are consistent.

Embodiment 2

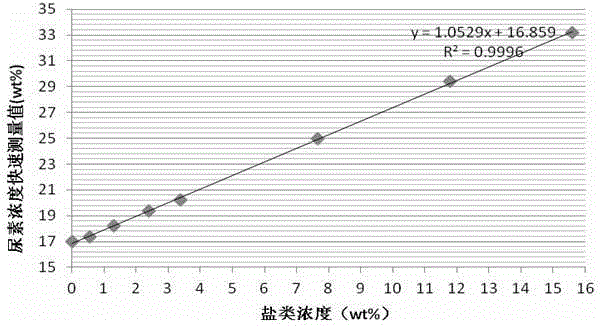

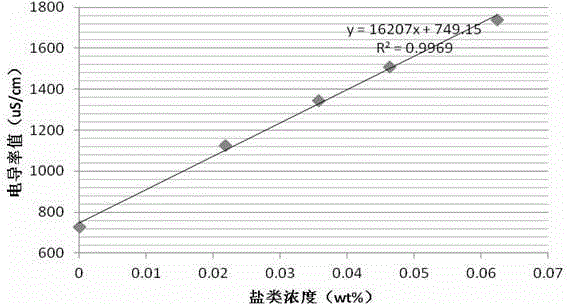

[0028] Such as figure 1As shown, take a random sample A, the appearance is clear, colorless and transparent, and meets the appearance requirements; first use the method in step 2 to take out the conductivity meter, pull out the electrode protective cover, turn on the power switch, and insert the test end vertically into the visually qualified In the urea reducing agent to be tested, the liquid surface is immersed in the protruding liquid level control line of the instrument, and the electrode end is slightly shaken to drive away the attached air bubbles. After the number displayed on the LCD screen is stable, read the value and it is the urea reducing agent to be tested. If the conductivity value is determined to be 421μS / cm, then use the method in step 3 to take out the urea reducing agent concentration measuring instrument, lift the protective cover of the refraction prism, and clean the refraction prism and On the surface of the cover plate, absorb the urea reducing agent t...

Embodiment 3

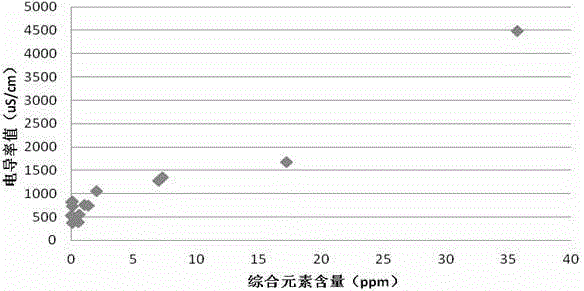

[0030] Take random sample B, the appearance is clear, colorless and transparent, first use the method in step 1 to visually judge whether it meets the appearance requirements; then use the method in step 2 to take out the conductivity meter, pull out the electrode protective cover, turn on the power switch, and connect the test terminal Insert vertically into the urea reducing agent to be tested that has passed the visual inspection, immerse the liquid level to the protruding liquid level control line of the instrument, shake the electrode end slightly to drive off the attached air bubbles, and read the value after the number displayed on the LCD screen is stable. is the conductivity value of the urea reducing agent to be tested, and the measured conductivity value is 1789μS / cm, which is determined to be a substandard product. In fact, the element content detection is carried out according to the national standard GB29518-2013 diesel engine nitrogen oxide reducing agent urea so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com