An arc-extinguishing magnetic circuit with dislocation distribution of magnetic steel and its DC relay

A technology of dislocation distribution and magnetic steel, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of small leakage flux, insufficient magnetic field strength, low magnetic utilization rate of magnetic steel, etc. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

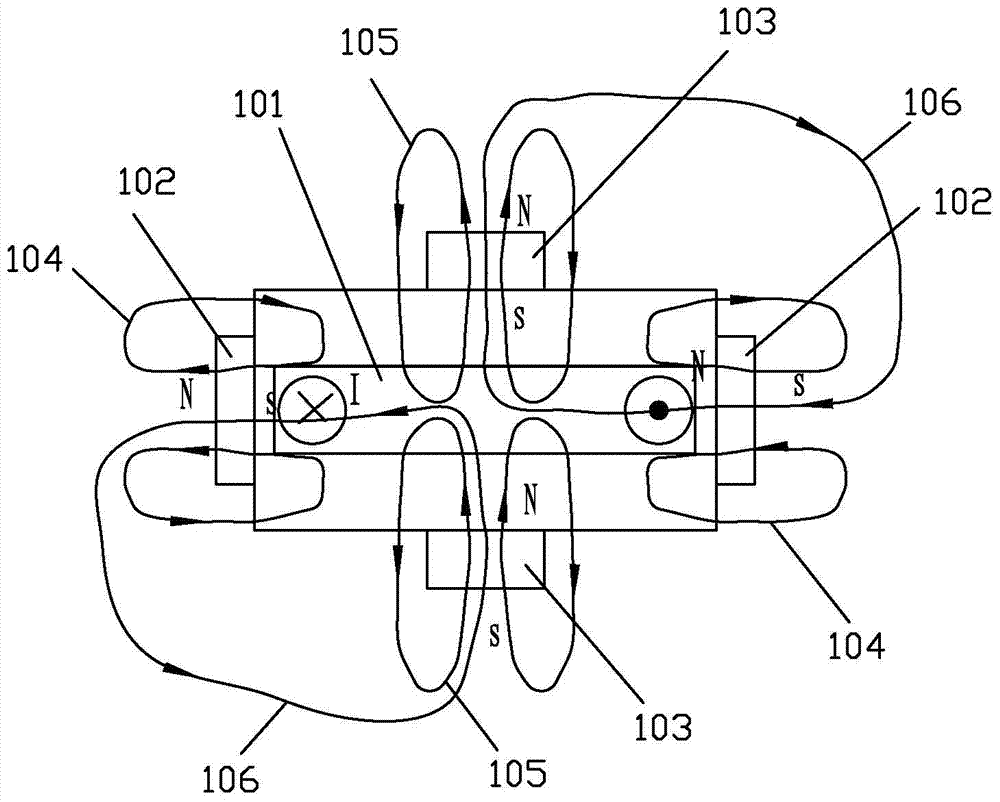

[0034] see image 3 As shown, the arc extinguishing magnetic circuit of a kind of magnetic steel dislocation distribution of the present invention includes a contact part, and the contact part includes two static contacts respectively used to provide current inflow and outflow, that is, the static contact 11 and the static contact 12 and a moving reed 21, the two ends of the moving reed 21 are respectively matched with two static contacts 11, 12, when the moving and static contacts are in contact together, the current I flows in from the static contact 11, After passing through the moving reed 21, it flows out from the static contact 12; a piece of first magnetic steel 31 is respectively provided on the outer sides of the two ends of the length of the moving reed 21; Two magnetic steels 32, wherein, the polarities of the two first magnetic steels 31 are opposite, and the polarities of the two second magnetic steels 32 are also opposite; the two second magnetic steels 32 are di...

Embodiment 2

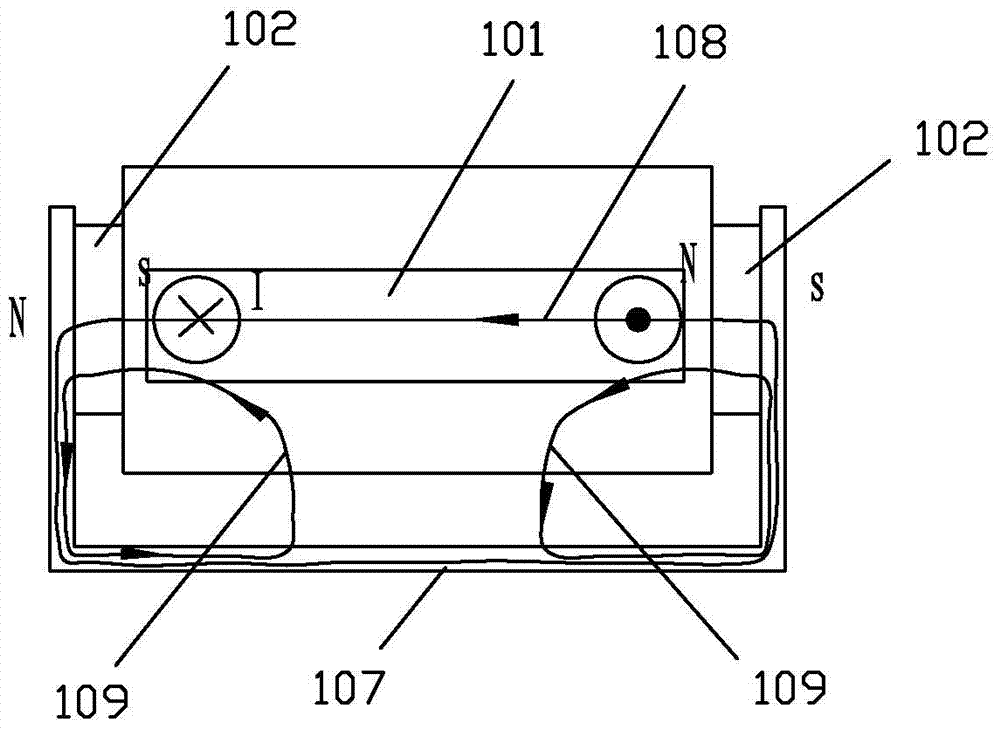

[0040] see Figure 4 to Figure 5 As shown, the arc extinguishing magnetic circuit with dislocation distribution of magnet steel in the present invention is different from the first embodiment in that the arc extinguishing magnetic circuit also includes two yoke clips 41 with magnetic conduction function, two The yoke clips 41 are respectively connected between the corresponding first magnetic steel 31 and the second magnetic steel 32; opposite sex. In this way, there are two groups of the first magnetic steel 31 and the second magnetic steel 32 connected with the yoke iron clip 41 around the mating periphery of the moving and static contacts.

[0041] Because of the yoke clip 41, the reluctance of the yoke clip is much smaller than the air reluctance. In this way, the magnetic flux of the magnet mainly goes to the yoke clip, so that the leakage flux between the two adjacent magnets becomes the main flux. In this way, the ampere force produced by the magnetic fields of the f...

Embodiment 3

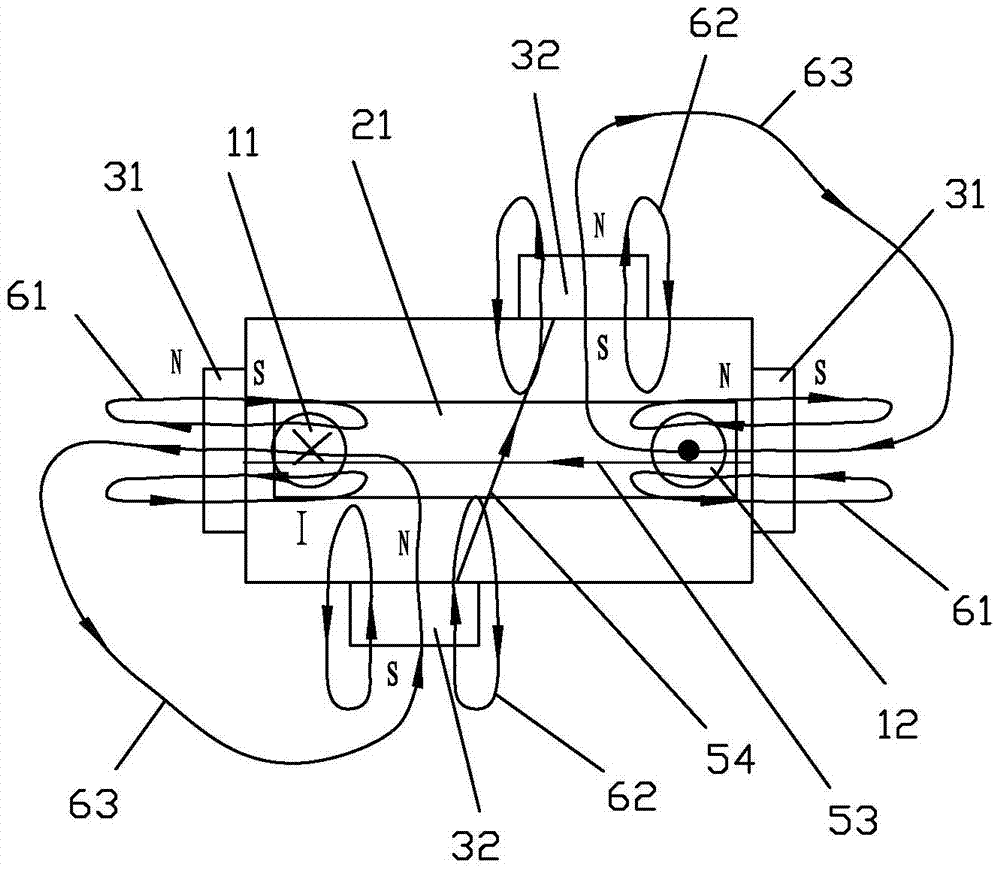

[0048] see Figure 6 As shown, the arc-extinguishing magnetic circuit and the DC relay of a kind of magnetic steel misalignment distribution of the present invention are different from the first embodiment in that the two second magnetic steels 32 are respectively arranged on two static contacts The positions where the heads 11, 12 are in contact with the movable reed 21, that is to say, the two second magnets 32 are respectively distributed corresponding to the positions where the movable and static contacts are in contact. In this way, the second magnetic steel 32 is closer to the corresponding first magnetic steel 31, and the second magnetic steel 32 is facing the contacts, so that the intensity of the arc extinguishing magnetic field and the magnetic field providing the ampere force to the moving spring can be enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com