A circuit floating installation structure

A technology for installing structures and circuits, which is applied in the direction of support structure installation, cooling/ventilation/heating transformation, etc., which can solve the problem of difficulty in ensuring good contact between the radiator and the inner wall of the electronic cabin, difficulty in installing circuit boards, radiators and support structures, and circuit The position of the board and the radiator itself cannot be adjusted, etc., so as to achieve the effect of good thermal environment adaptability, good heat dissipation, and increased gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

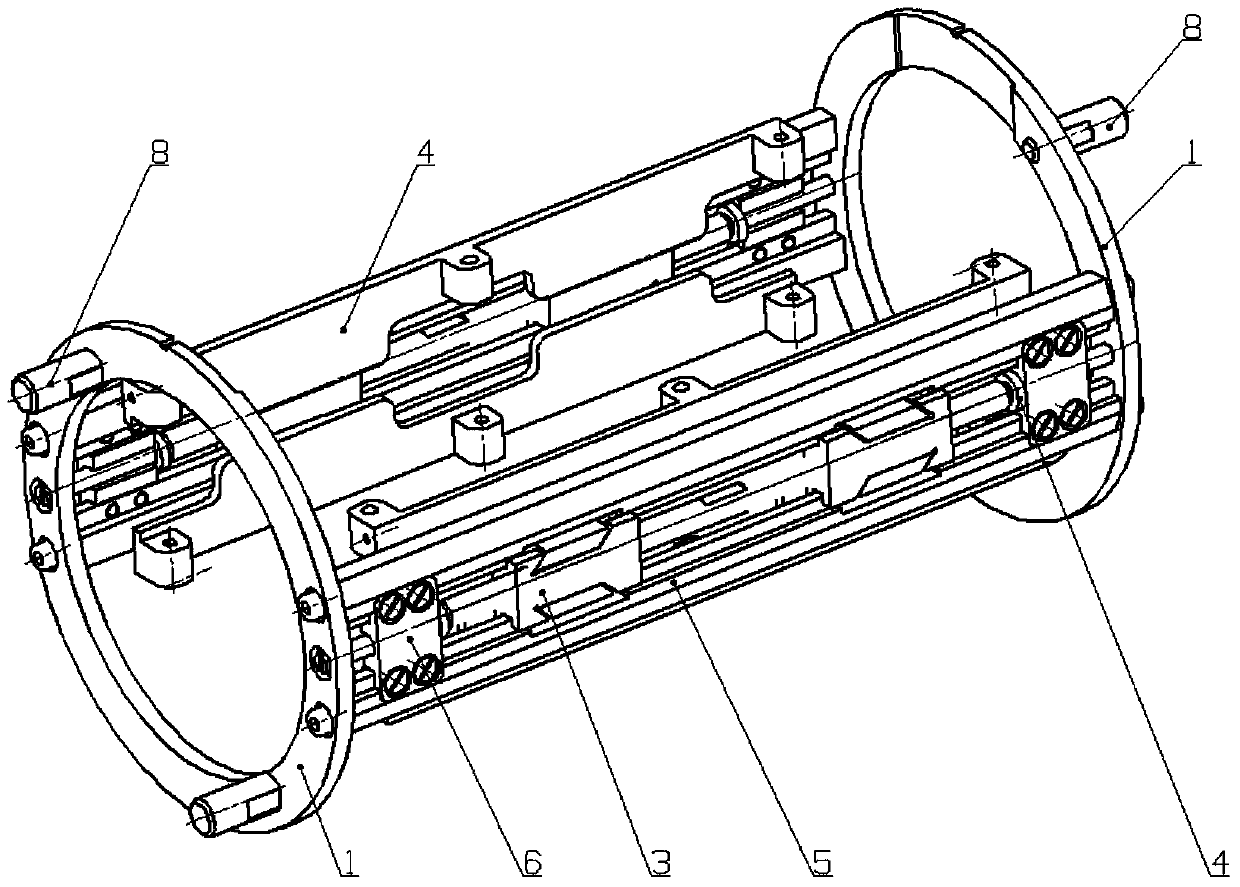

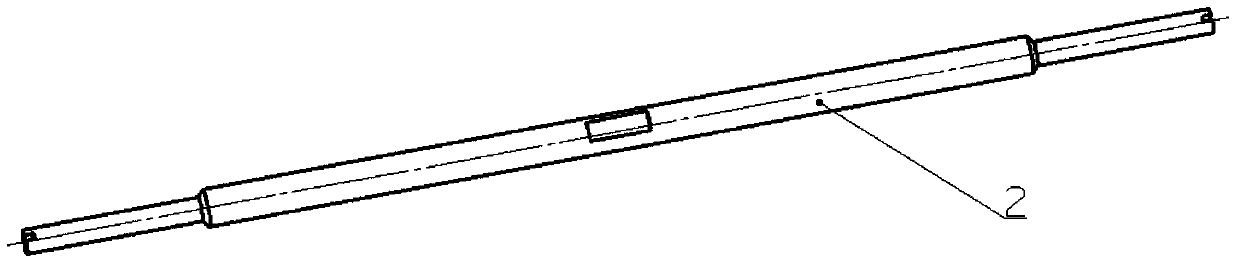

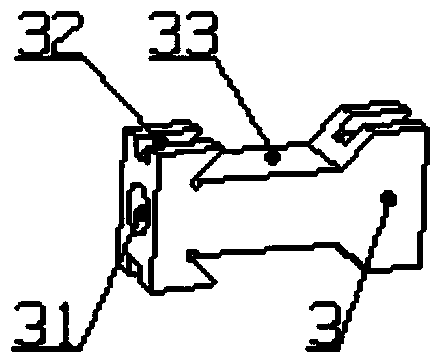

[0031] Such as Figure 1-9 As shown, a circuit floating installation structure includes: a support frame 1, on which at least one set of reverse thread mechanisms that can float up and down are correspondingly installed, and any set of reverse thread mechanisms includes two At least one set of spaced apart circuit boards 10 and a heat sink 20 are installed between the two oppositely mounted reverse screw components, and the heat sink 20 is driven by the reverse screw mechanism When moving to the set height, it abuts against the bulkhead of the electronic cabin where it is located, optimizing the heat conduction path from the electronic components to the inner wall of the electronic cabin.

[0032] The supporting frame 1 is used to connect the reverse screw mechanism to the outside on the one hand, and on the other hand to install t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com