Ferritic stainless steel sheet having excellent anti-bacterial activity, and method for producing same

A technology of stainless steel plate and manufacturing method, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of antibacterial and softening, peeling, antibacterial reduction, etc., and achieve excellent antibacterial, good antibacterial, Antibacterial effect of softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

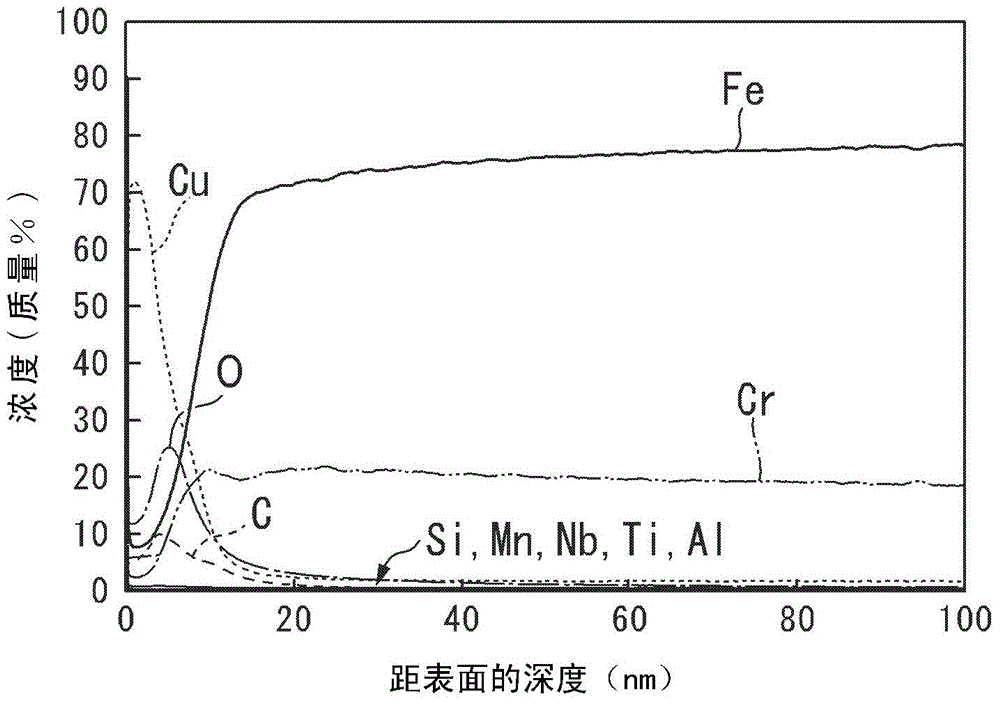

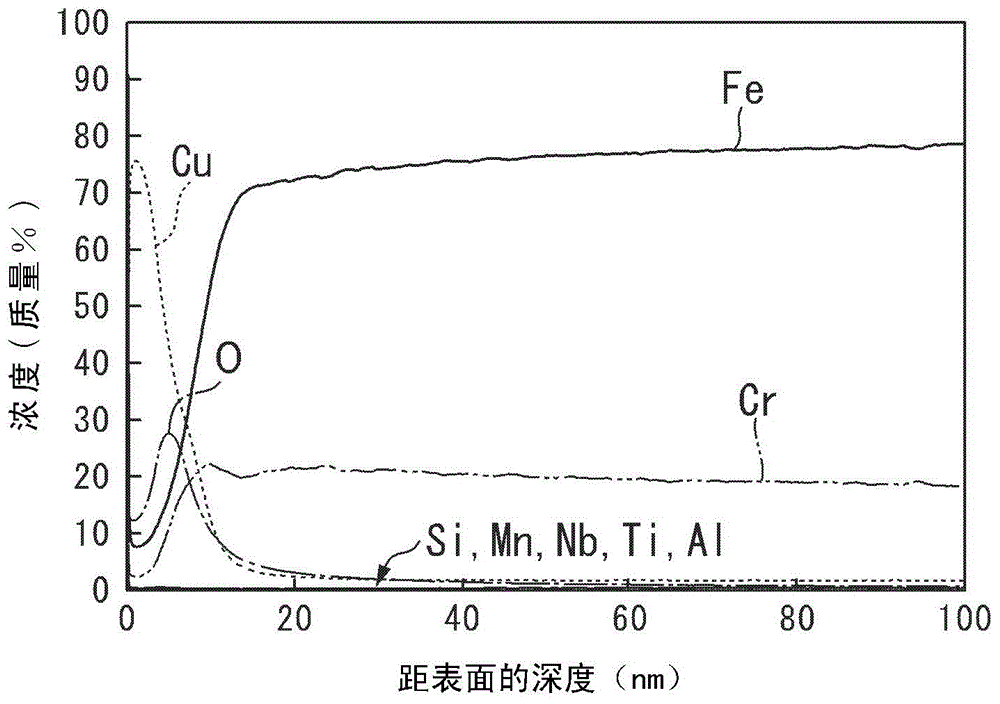

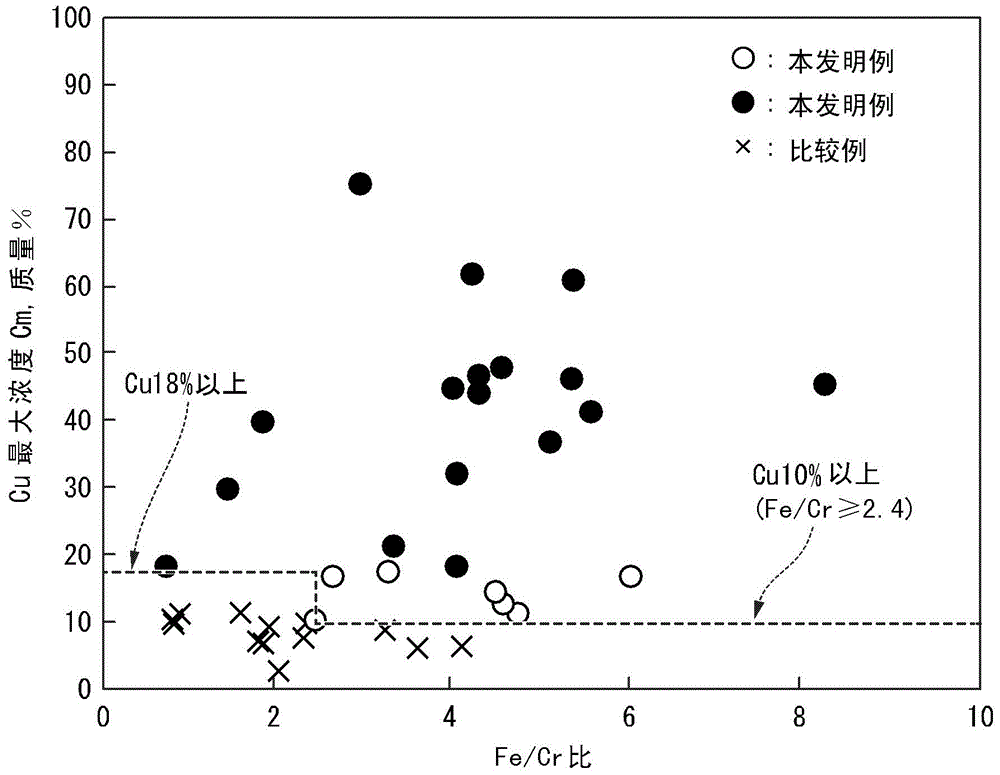

[0148] The steel whose composition is shown in Table 1A and Table 1B is smelted by vacuum melting, hot rolled at a heating temperature of 1100-1350°C and a final hot rolling temperature of 700-1020°C, and coiled at a coiling temperature of 400-700°C Roll down. Next, the hot-rolled sheet was annealed at 980° C. for 10 seconds in the air, and then ordinary pickling was performed. Next, cold rolling and final annealing are performed to obtain a cold-rolled sheet having a thickness of 1.0 to 1.3 mm. Thereafter, pickling is performed in sulfuric acid and hydrofluoric nitric acid at 40 to 80° C. to produce a ferritic stainless steel plate. In addition, in Table 1A and Table 1B, the column marked with "-" shows that the said element was not added, and therefore it was not measured.

[0149] The following evaluations were performed on the obtained ferritic stainless steel sheets. In addition, in this Example, in order to confirm whether favorable antimicrobial property is expressed...

Embodiment 2

[0161] Next, in order to confirm the softening effect of this embodiment, the conditions of the hot-rolled sheet annealing step and the final annealing step were changed to the conditions shown in Table 15 during the production of some steel types in Table 1A and Table 1B.

[0162] In addition, in Example 2, the hot rolling process, the cold rolling process, and the final pickling process were implemented under the conditions within the range of this embodiment.

[0163] The cross-sectional hardness and corrosion resistance were evaluated for each of the manufactured steel sheets. In addition, the cross-sectional hardness was measured by the following method. Five locations were arbitrarily selected in the vicinity of the plate thickness center, Vickers hardness tests were performed on the selected locations, and the average value thereof was set as the measured value of the cross-sectional hardness. Corrosion Resistance In accordance with JIS Z2371, a 308K 5% NaOH solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com