Power module

A power module and power cycle technology, applied in semiconductor/solid-state device parts, welding equipment, manufacturing tools, etc., can solve problems such as thermal resistance rise, solder cracking, etc., to achieve improved reliability, high reliability, and sufficient reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

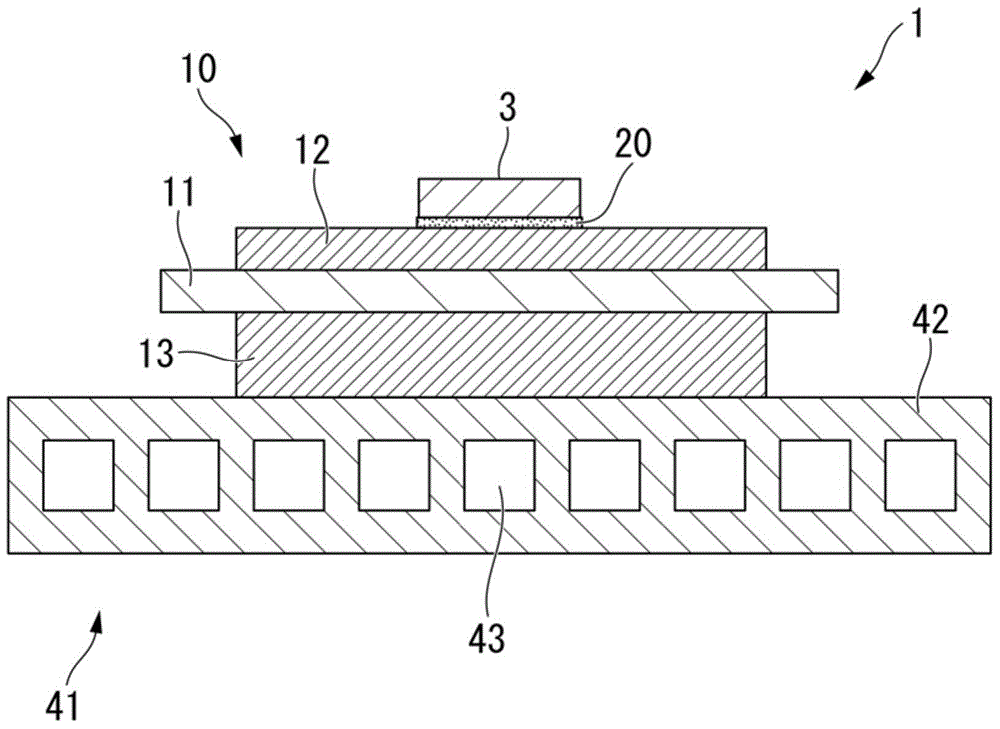

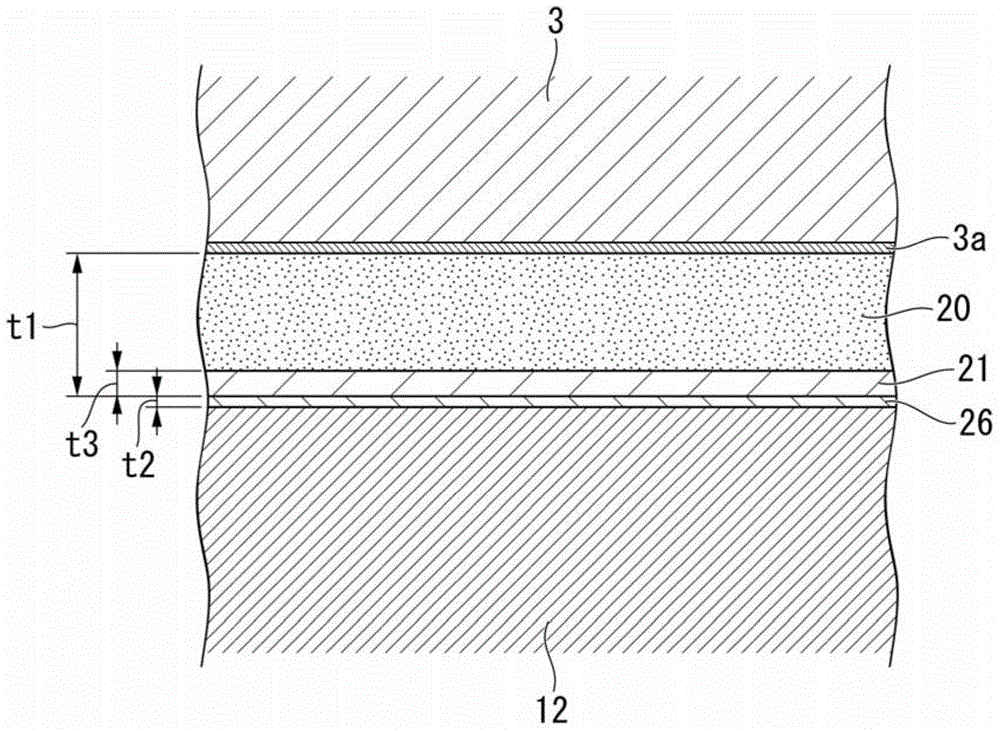

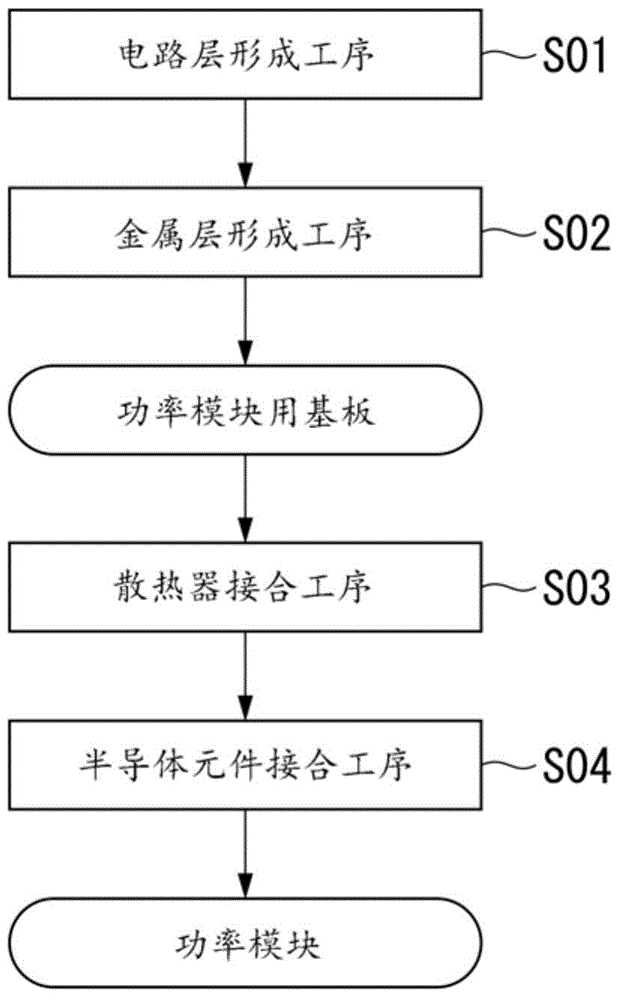

[0037] figure 1 The power module 1 according to the first embodiment of the present invention is shown in . This power module 1 includes a power module substrate 10 in which a circuit layer 12 is disposed on one surface (first surface) of an insulating substrate (insulating layer) 11, and a power module mounted on the circuit layer 12 ( figure 1 The middle is the upper surface) of the semiconductor element 3 . In addition, in the power module 1 of the present embodiment, the heat sink 41 is bonded to the other surface side (the second surface side, the second surface side) of the insulating substrate 11 . figure 1 middle is the lower surface).

[0038] The power module substrate 10 includes: an insulating substrate 11 constituting an insulating layer; figure 1 and the circuit layer 12 arranged on the other side of the insulating substrate 11 (being the second side, figure 1 The middle is the metal layer 13 of the lower surface).

[0039] The insulating substrate 11 is a s...

no. 2 Embodiment approach

[0069] Next, a power module according to a second embodiment of the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same member as 1st Embodiment, and detailed description is abbreviate|omitted.

[0070] Figure 5 A power module 101 according to the second embodiment of the present invention is shown in . This power module 101 includes a power module substrate 110 in which a circuit layer 112 is formed on one surface (first surface) of an insulating substrate (insulating layer) 11, and a substrate mounted on the circuit layer 112 ( Figure 5 The middle is the upper surface) of the semiconductor element 3 .

[0071] The power module substrate 110 includes: an insulating substrate 11 constituting an insulating layer; Figure 5 and the circuit layer 112 arranged on the other side of the insulating substrate 11 (being the second side, Figure 5 The middle is the metal layer 13 of the lower surfa...

Embodiment 1

[0114]Hereinafter, the results of confirmation experiments conducted to confirm the effects of the present invention will be described.

[0115] The power module described in the first embodiment is prepared. The insulating substrate is made of AlN, and a substrate with a size of 27 mm×17 mm and a thickness of 0.6 mm is used. In addition, the circuit layer was made of oxygen-free copper, and a layer of 25 mm×15 mm and a thickness of 0.3 mm was used. The metal layer is made of 4N aluminum, and a layer of 25 mm×15 mm and a thickness of 0.6 mm is used. The semiconductor element was an IGBT element, and an element with a size of 13 mm×10 mm and a thickness of 0.25 mm was used. An aluminum plate (A6063) of 40.0 mm x 40.0 mm x 2.5 mm was used as the heat sink.

[0116] Here, the thickness of the Ni plating film formed on the surface of the circuit layer was adjusted, and the composition of the solder material was changed as shown in Table 1, thereby adjusting the composition of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com