New type dipping machine

A dipping machine and dipping technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as poor stability and reliability of motion, influence of dipping liquid, and high energy consumption of motion, etc., and achieve compact structure , improve quality and efficiency, and achieve high running stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

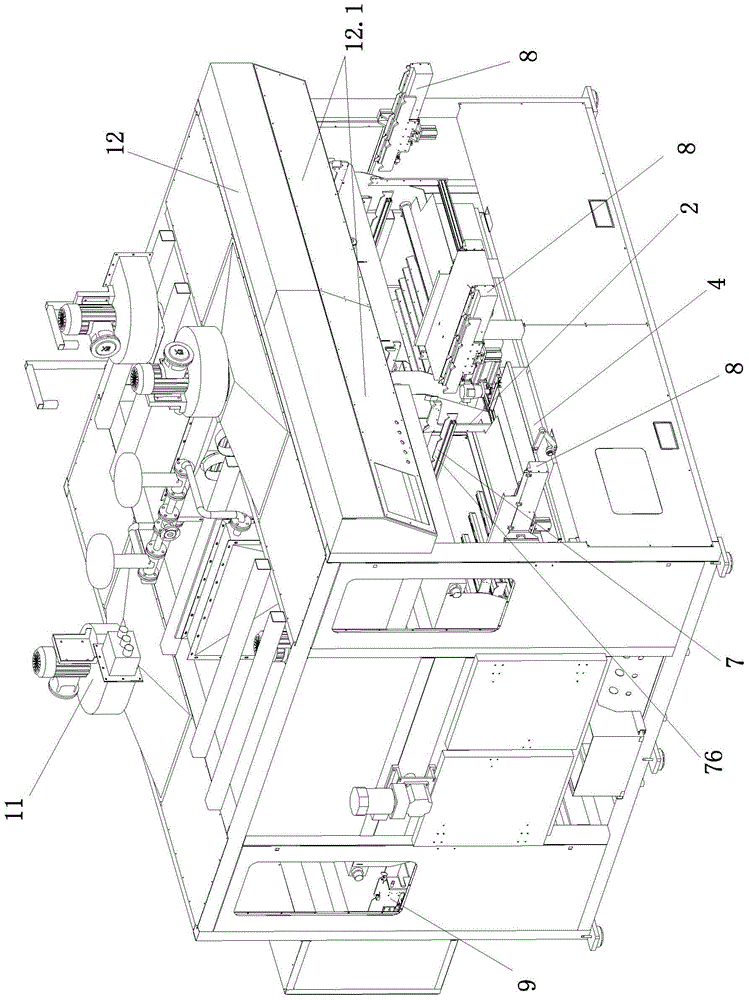

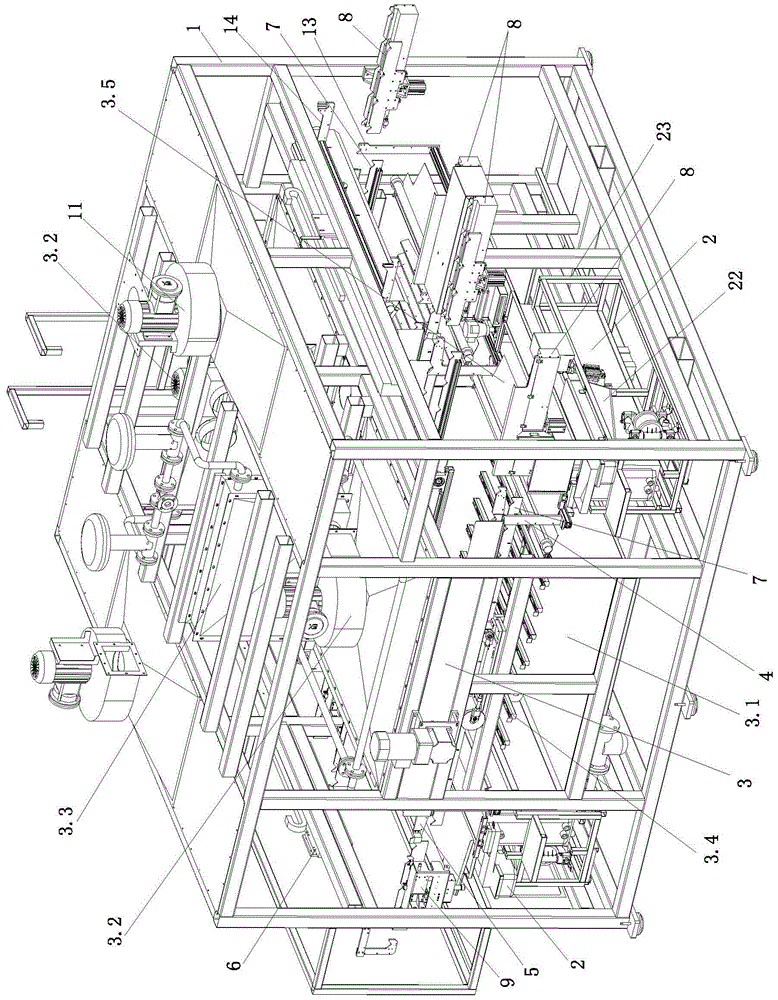

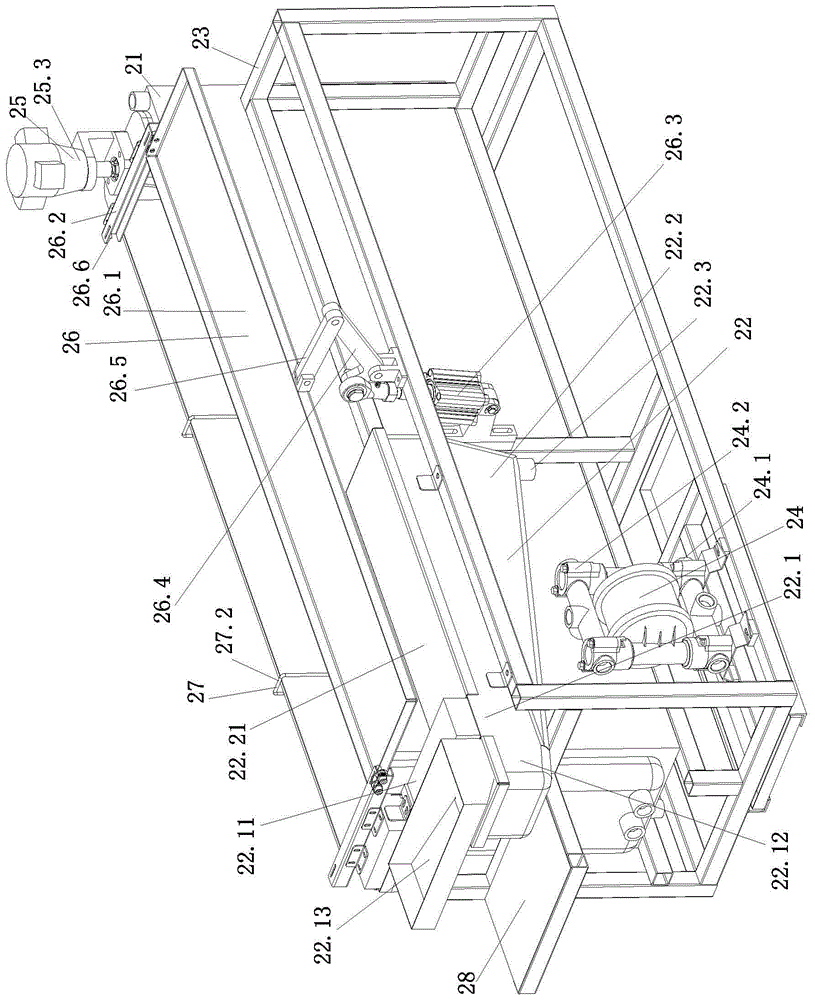

[0023] Such as Figure 1 to Figure 1 1, the present invention includes a frame 1, three dipping tank assemblies 2, first and second oven assemblies 3, front and rear dipping manipulator assemblies 4,5, several workpiece hangers 10 and a control cabinet 12. The workpiece hanging rod 10 is provided with several hanging points for hanging workpieces. The control cabinet includes a PLC [programmable logic controller, not shown in the figure], an input and output unit and an outer cover of the control cabinet, and the output unit includes a display screen and an audible and visual alarm device. The control cabinet is set on the frame in front of the oven body of the two oven assemblies, wherein the control cabinet is provided with two output units 12.1, and the two output units are located at the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com