Method for preparing wear-resistant and corrosion-resistant alloy pipe fittings by powder metallurgy process

A technology of powder metallurgy and corrosion-resistant alloys, which is applied in the field of powder metallurgy to prepare wear-resistant and corrosion-resistant alloy pipe fittings, which can solve the problems of increased overall cost of alloys, adverse effects of alloy properties, segregation of alloy elements, etc., to prevent the rise of oxygen content in molten steel , reduce production costs, and accelerate the effect of floating and removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

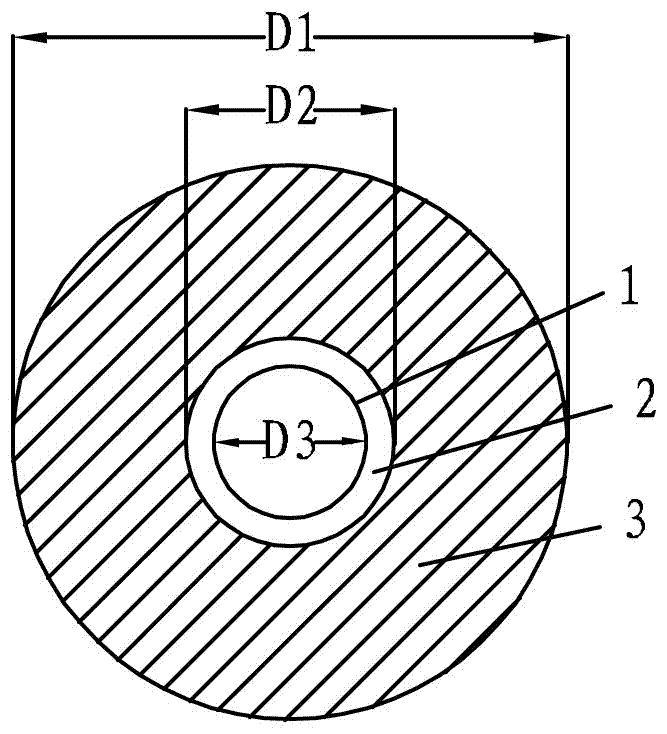

Image

Examples

Embodiment 1

[0033] This embodiment relates to a method for preparing wear-resistant and corrosion-resistant alloy pipe fittings by powder metallurgy, including the following preparation steps:

[0034] Step 1. Prepare a powder of iron-based alloy with wear-resistant and corrosion-resistant properties. The mass percentage of the chemical composition of the alloy is C: 2.68%; W: 0.5%; Mo: 1.3%; Cr: 16.5%; V: 8.3%; Nb: 2.0%; Co: 0.2%; Si: 0.6%; Mn: 0.3%; N: 0.12%; O: 0.006%; the balance is iron and impurities. The alloy powder is prepared by non-vacuum powder metallurgy process, and the powder metallurgy process steps are as follows:

[0035] a. Transfer the molten steel to the ladle, and the loading weight of the molten steel is 3 tons;

[0036] b. The upper surface of the molten steel in the ladle is covered with ladle mold slag, and the ladle mold slag is heated to maintain the superheat of the molten steel at 110°C; nitrogen gas is introduced at the bottom of the ladle to stir the molte...

Embodiment 2

[0044] This embodiment relates to a method for preparing wear-resistant and corrosion-resistant alloy pipe fittings by powder metallurgy, including the following preparation steps:

[0045] Step 1. Prepare a powder of iron-based alloy with wear-resistant and corrosion-resistant properties. The mass percentage of the chemical composition of the alloy is calculated as C: 2.08%; W: 0.5%; Mo: 1.5%; Cr: 16.5%; V: 4.6%; Nb: 1.8%; Co: 0.3%; Si: 0.6%; Mn: 0.5%; N: 0.08%; O: 0.006%; the balance is iron and impurities. The alloy powder is prepared by non-vacuum powder metallurgy process, and the powder metallurgy process steps are as follows:

[0046] a. The molten steel is transferred to the ladle, and the loading weight of the molten steel is 5 tons;

[0047] b. The upper surface of the molten steel in the ladle is covered with ladle mold slag, and the ladle mold slag is heated to maintain the superheat of the molten steel at 150°C; argon gas is introduced at the bottom of the ladle ...

Embodiment 3

[0055] This embodiment relates to a method for preparing wear-resistant and corrosion-resistant alloy pipe fittings by powder metallurgy, including the following preparation steps:

[0056] Step 1. Prepare a powder of iron-based alloy with wear-resistant and corrosion-resistant properties. The mass percentage of the chemical composition of the alloy is calculated as C: 2.1%; W: 0.5%; Mo: 1.5%; Cr: 22.0%; V: 4.0%; Nb: 1.0%; Co: 0.2%; Si: 0.8%; Mn: 0.4%; N: 0.05%; O: 0.008%; the balance is iron and impurities. The alloy powder is prepared by non-vacuum powder metallurgy process, and the powder metallurgy process steps are as follows:

[0057] a. Transfer the molten steel to the ladle, and the loading weight of the molten steel is 7 tons;

[0058] b. The upper surface of the molten steel in the ladle is covered with ladle mold slag, and the ladle mold slag is heated to maintain the superheat of the molten steel at 135°C; nitrogen gas is introduced at the bottom of the ladle to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com