Water turbine blade modified epoxy resin multi-coating anti-corrosion anti-abrasion method

An epoxy resin and multi-coating technology, which is applied in the field of materials, can solve the problems of water turbine impeller material damage, etc., and achieve the effects of improved cavitation resistance, tight combination, and improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

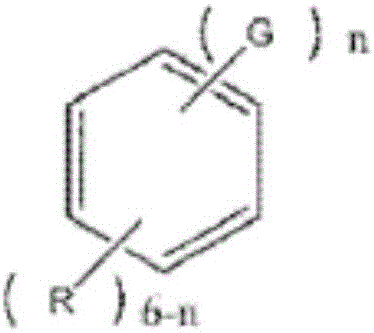

Image

Examples

Embodiment 1

[0031] A method for preventing corrosion and abrasion of water turbine blades, comprising:

[0032] (1) Carry out sandblasting roughening on blade surface;

[0033] (2) cleaning the roughened blade surface with acetone and ethanol and drying;

[0034] (3) according to the proportioning of hard graphene fiber 2wt% and hydroxyl-terminated liquid rubber-modified epoxy resin surplus, make slurry and mix homogeneously;

[0035] (4) the slurry is uniformly applied on the surface of the blade, and dried at 90° C. to obtain a wear-resistant and corrosion-resistant coating of hydroxyl-terminated liquid rubber-modified epoxy resin doped with graphene fibers cladding on the surface of the blade;

[0036] (5) According to the hard WC ceramic particles accounted for 20wt%, Si 3 N 4 The proportioning of 15wt% of nanoparticles, 2wt% of high-density polyethylene fiber and the remainder of hydroxyl-terminated liquid rubber-modified epoxy resin is made into slurry and mixed uniformly;

[00...

Embodiment 2

[0039] A method for preventing corrosion and abrasion of water turbine blades, comprising:

[0040] (1) Carry out sandblasting roughening on blade surface;

[0041] (2) cleaning the roughened blade surface with acetone and ethanol and drying;

[0042] (3) according to the proportioning of hard graphene fiber 10wt% and hydroxyl-terminated liquid rubber modified epoxy resin surplus, make slurry and mix homogeneously;

[0043] (4) Apply the slurry evenly on the surface of the blade and dry at 130° C. to obtain a wear-resistant and corrosion-resistant coating of hydroxyl-terminated liquid rubber-modified epoxy resin doped with graphene fibers cladding on the surface of the blade;

[0044] (5) According to the hard WC ceramic particles accounted for 65wt%, Si 3 N 4 The proportioning of 5wt% of nanoparticles, 10wt% of high-density polyethylene fiber and the remainder of hydroxyl-terminated liquid rubber-modified epoxy resin is made into slurry and mixed uniformly;

[0045] (6) A...

Embodiment 3

[0047] A method for preventing corrosion and abrasion of water turbine blades, comprising:

[0048] (1) Carry out sandblasting roughening on blade surface;

[0049] (2) cleaning the roughened blade surface with acetone and ethanol and drying;

[0050] (3) according to the proportioning of hard graphene fiber 5wt% and hydroxyl-terminated liquid rubber modified epoxy resin surplus, make slurry and mix homogeneously;

[0051] (4) Apply the slurry evenly on the surface of the blade and dry at 100° C. to obtain a wear-resistant and corrosion-resistant coating of hydroxyl-terminated liquid rubber-modified epoxy resin doped with graphene fibers cladding on the surface of the blade;

[0052] (5) According to the hard WC ceramic particles accounted for 50wt%, Si 3 N 4 The proportioning of 10wt% of nanoparticles, 5wt% of high-density polyethylene fiber and the remainder of hydroxyl-terminated liquid rubber-modified epoxy resin is made into slurry and mixed uniformly;

[0053] (6) Appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com