A vacuum suction cup palletizing manipulator

A vacuum suction cup and manipulator technology, applied in the field of palletizing manipulators, can solve problems such as unfavorable continuous production, frequent movements, and increase labor intensity, and achieve the effects of improving surface appearance quality, reducing maintenance workload, and improving overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

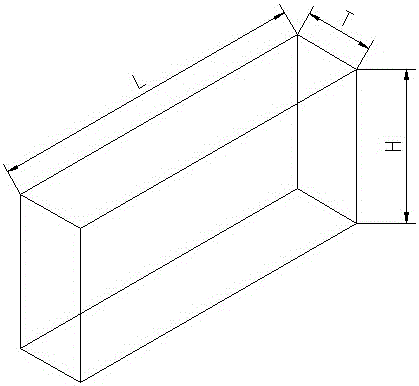

[0026] A vacuum suction cup palletizing manipulator comprises a frame 1, and a floating frame 2 is arranged under the frame 1, and the floating frame 2 can float up and down relative to the frame 1, and parallel beams are distributed under the floating frame 2.

[0027] In this embodiment, the floating frame 2 is connected with the frame 1 through the guide rod 16, the upper end of the guide rod 16 is movably connected to the frame 1, and the lower end of the guide rod 16 is fixedly connected with the floating frame 2. The part between the frame 1 and the floating frame 2 is sheathed with a floating spring 17 .

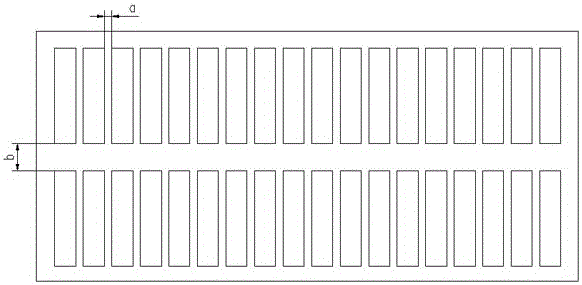

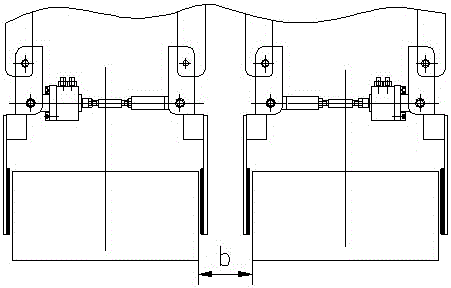

[0028] In this embodiment, there are two beams, one of which is fixedly connected to the floating frame, such as Figure 5 Fixed beam 3 shown. The other beam is connected with the floating frame 2 through the guide rail Ⅱ9 and the slider Ⅱ10, such as Figure 5 In the movable beam 11 shown, the guide rail II9 is fixed on the floating frame 2, the slider II10 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com