Skid-mounted unit for receiving and storing methanol

A methanol and skid-mounted technology, applied in the field of methanol receiving and storage skid-mounted devices, can solve the problems of equipment investment waste, high overall investment, long construction period, etc., and achieve the effects of cost saving, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

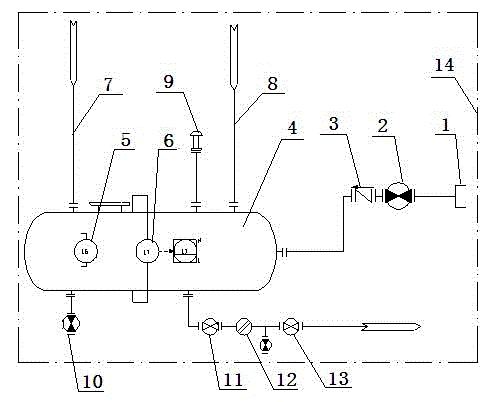

[0021] In order to prevent the formation of natural gas hydrate, a methanol storage skid is set up at the well site or gas gathering station to store a certain amount of methanol for a certain period of time to meet the injection requirements of methanol inhibitors for the normal production of gas wells; and to overcome the inconvenience of moving the existing methanol storage device and cause equipment investment waste, and the alcohol injection equipment needs to be installed on site, the construction period is long, and the overall investment is high. This embodiment provides a method such as figure 1 The shown methanol receiving and storage skid-mounted device includes a methanol storage tank 4, which is arranged on a movable skid base 14, and the feed pipeline of the methanol storage tank 4 is arranged from right to left Quick connector 1 and shut-off valve one 2, the outlet pipeline at the bottom of the methanol storage tank 4 is connected to the methanol injection pump, ...

Embodiment 2

[0027] This embodiment provides a methanol receiving and storage skid-mounted device, including a methanol storage tank 4, the methanol storage tank 4 is arranged on a movable skid base 14, and the feed line of the methanol storage tank 4 runs from the right A quick connector 1 and a shut-off valve 1 are provided to the left, and the outlet pipeline at the bottom of the methanol storage tank 4 is connected to a methanol injection pump, and a shut-off valve 2 11, a filter 12 and a methanol outlet shut-off valve are arranged on the outlet pipeline from left to right 13. The bottom of the methanol storage tank 4 is also provided with a blowdown pipeline, and a shut-off valve 3 10 is set on the blowdown pipeline. The upper end of the methanol storage tank 4 is connected with a nitrogen pipeline 7 and a pump methanol return pipeline 8 .

[0028] At the same time, a check valve 3 is arranged on the feed line of the methanol storage tank 4 behind the cut-off valve 2, and a check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com