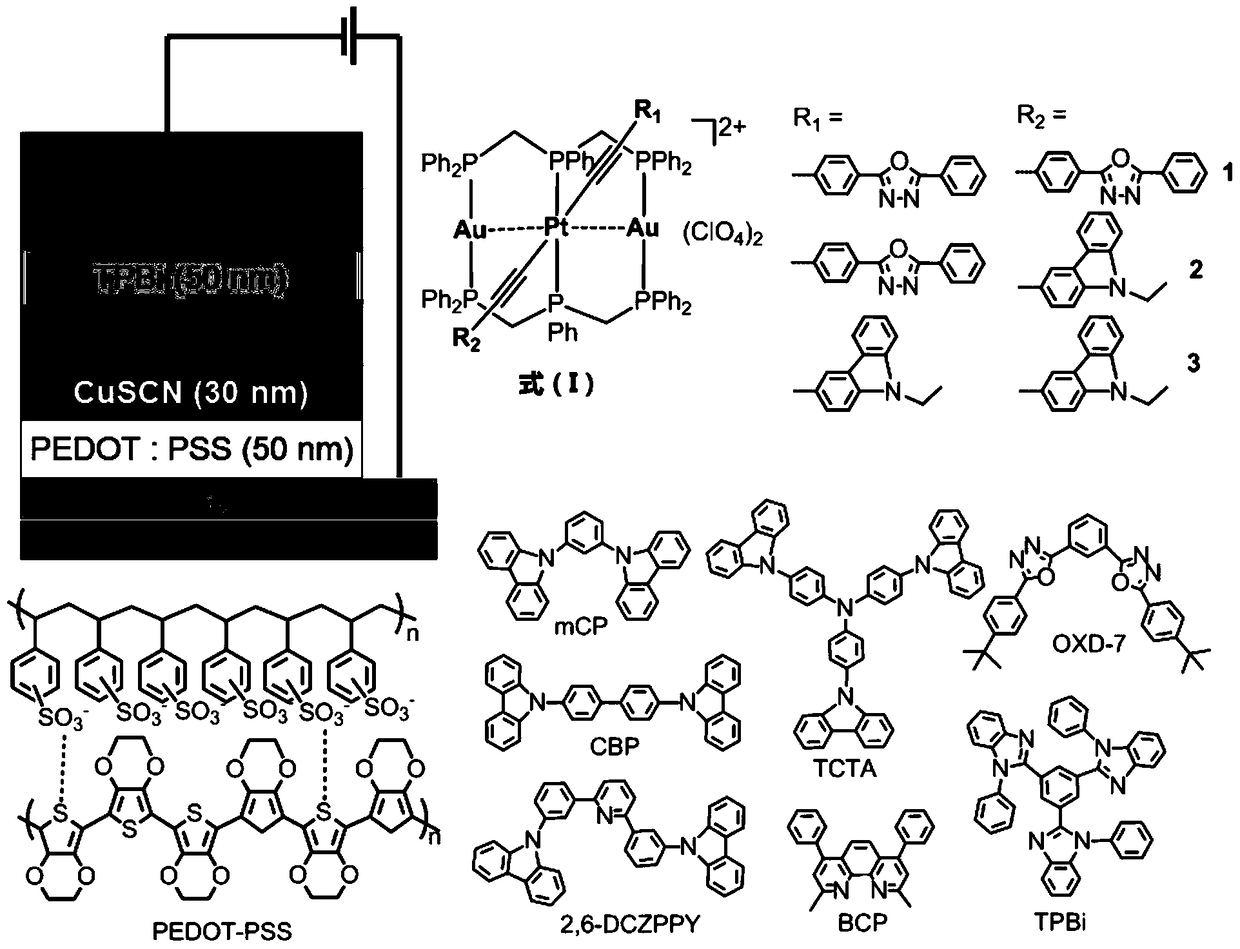

An ionic phosphorescent ptm2 complex and its preparation method and use

A phosphorescent complex and complex technology are applied in chemical instruments and methods, luminescent materials, semiconductor/solid-state device manufacturing, etc., which can solve problems such as limiting the development and commercial application of organic light-emitting diodes, poor firmness, and complicated processes, and achieve Effects of high electroluminescent external quantum conversion efficiency, improved energy transfer efficiency, and high electro-optical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

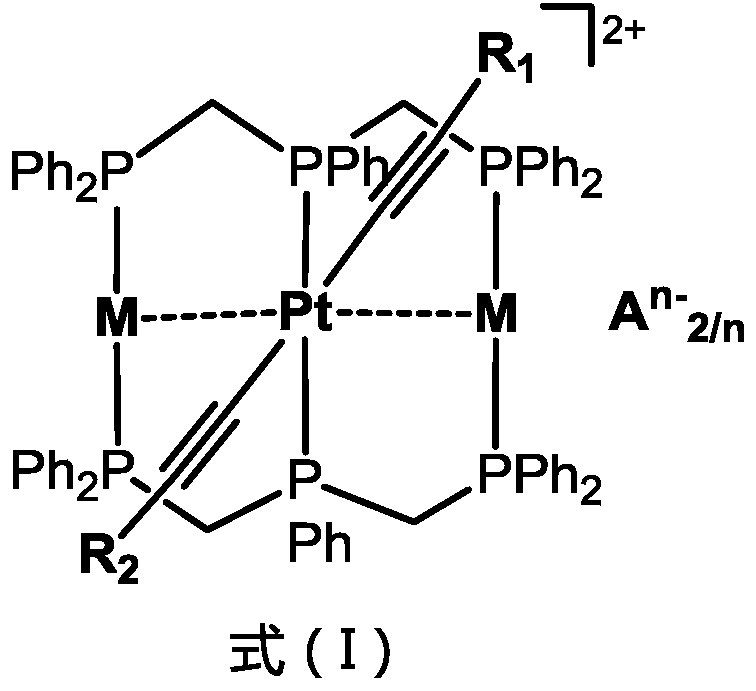

Method used

Image

Examples

Embodiment 1

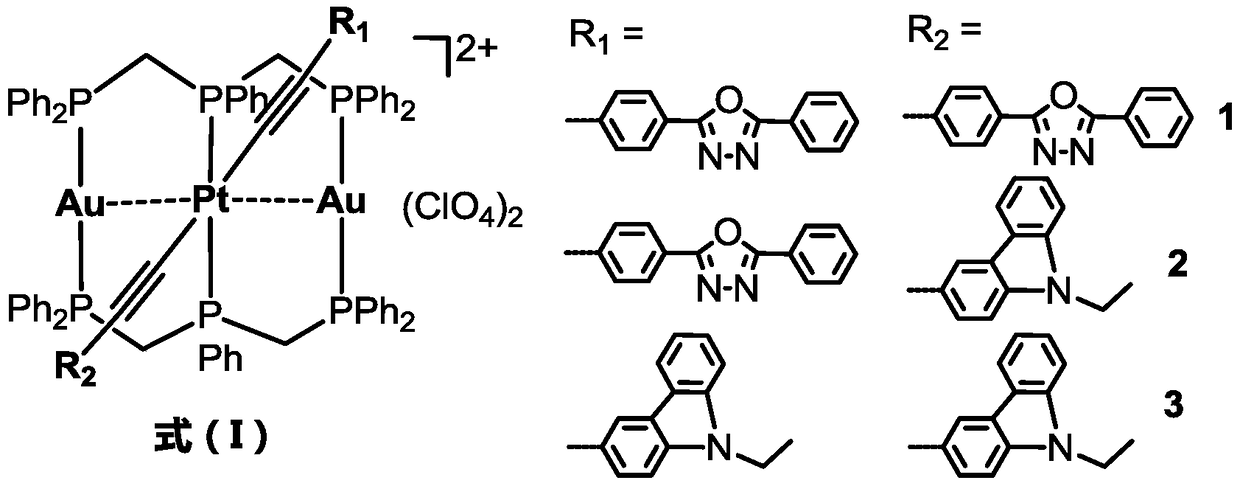

[0049] Embodiment 1: Complex [PtAu 2 (dpmp) 2 (C≡C-OXD) 2 ](ClO 4 ) 2 (1) Preparation

[0050] [Au(tht) was dissolved in 20mL 2 ]ClO 4 (47.3mg, 0.1mmol) in dichloromethane solution was added Ph 2 P(CH 2 PPh 2 ) 2 . After stirring for 30 minutes, 5 mL of Pt(PPh 3 ) 2 (C≡C-OXD) 2 (61.3mg, 0.05mmol) in dichloromethane. The reaction solution turned yellow-green after being stirred at room temperature for 4 hours. The product was purified by silica gel column chromatography using CH 2 Cl 2 -MeCN(8:1) was the eluent to collect the yellow-green product. Yield: 85%. Elemental analysis (C 96 h 76 Au 2 Cl 2 N 4 o 10 P 6 Pt) Calculated: C, 50.32; H, 3.34; N, 2.45. Measured: C, 50.41; H, 3.28; N, 2.54. Electrospray mass spectrum m / z (%): 2191.4 (86) [M-ClO 4 ] + ,1045.4(100)[M-2ClO 4 ] 2+ . NMR phosphorus spectrum (CDCl 3 ,ppm):8.22-8.16(m, 4H),8.03-7.94(m,6H),7.93-7.88(d,4H,J=9.0Hz),7.65-7.57(m,24H),7.56-7.50 (m ,12H),7.33-7.23(m,8H),7.14-7.06(t,6H,J=7.0Hz...

Embodiment 2

[0051] Embodiment 2: Complex [PtAu 2 (dpmp) 2 (C≡C-9-Etcarb-3)(C≡C-OXD)](ClO 4 ) 2 (2) Preparation.

[0052] The preparation method is basically the same as the method in Example 1, only using Pt(PPh 3 ) 2 (C≡C-9-Etcarb-3)(C≡C-OXD) instead of Pt(PPh 3 ) 2 (C≡C-OXD) 2 . Yield: 78%. Elemental analysis (C 96 h 79 Au 2 Cl 2 N 3 o 9 P 6 Pt) Calculated: C, 50.92; H, 3.52; N, 1.86. Measured: C, 50.58; H, 3.51; N, 1.82. Electrospray mass spectrum (%); 4 ] + ,1033.1(63) [M-2ClO 4 ] 2+ . H NMR spectrum (CDCl 3 ,ppm):8.21-8.16(m,2H),8.05-7.82(m,16H), 7.65-7.49(m,18H),7.45-7.37(m,8H),7.31-7.20(m,7H),7.15 -7.05(m,10H), 6.96-6.90(d,2H,J=8.1Hz),6.87-6.74(m,3H),5.48-5.36(m,4H),4.61-4.50(m,2H),4.45 -4.34 (m, 4H), 1.48-1.12 (t, 3H, J = 7.1Hz). Nuclear Magnetic Resonance Phosphorus Spectrum (CDCl 3 , ppm):.31.3(m,2P,J P-P =30.0Hz),6.0(m,1P,J P-P =30.3Hz,J Pt-P = 2487Hz). Infrared spectrum (KBr, cm -1 ): 2106(w), 1099(s).

Embodiment 3

[0053] Embodiment 3: Complex [PtAu 2 (dpmp) 2 (C≡C-9-Etcarb-3) 2 ](ClO 4 ) 2 (3) Preparation.

[0054] The preparation method is basically the same as the method in Example 1, only using Pt(PPh 3 ) 2 (C≡C-9-Etcarb-3) 2 Instead of Pt(PPh 3 ) 2 (C≡C-OXD) 2 . Yield: 83%. Elemental analysis (C 96 h 82 Au 2 Cl 2 N 2 o 8 P 6 Pt) Calcd: C, 51.53; H, 3.69; N, 1.25. Measured values: C, 51.82; H, 3.59; N, 1.22. Electrospray mass spectrum m / z(%): 2136.5(88)[M-ClO 4 ] + ,1018.8(100)[M-2ClO 4 ] 2+ . H NMR spectroscopy (CDCl 3 ,ppm):8.01-7.90(m,12H),7.86-7.82(d,2H,J=7.2Hz),7.65-7.56(m,8H), 7.55-7.41(m,6H),7.40-7.30(m ,14H),7.26-7.16(m,6H),7.12-7.0(m,12H), 6.84-6.75(t,4H,J=7.5Hz),5.62-5.41(m,4H),4.52-4.41(m , 4H), 4.40-4.31 (m, 4H), 1.44-1.40 (t, 6H, J=7.2Hz). Phosphorus NMR spectrum (CDCl 3 ,ppm):31.2(m,2P,J P-P = 30.5Hz), 6.42(m,1P,JP-P =30.3Hz,J Pt-P = 2526Hz). Infrared spectrum (KBr, cm -1 ): 2112(w), 1098(s).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com