Pure cotton fabric moisture-absorbing/sweat-releasing finishing method

A technology for moisture absorption and perspiration, pure cotton fabrics, applied in the field of clothing and textiles, can solve the problems of slow moisture release of pure cotton fabrics, reduced fabric thermal insulation performance, and clothes sticking to the skin, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

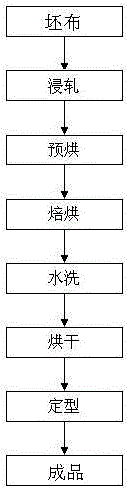

[0032] A method for moisture absorption and perspiration finishing of 14.5tex pure cotton fine cloth, comprising the following steps: gray cloth → padding → pre-baking → baking → washing → drying → shaping → finished product;

[0033] Padding: put the fabric into the rolling tank at room temperature and heat up the water, and at the same time add the finishing agent polysiloxane for padding, the concentration is 40g / L, and adjust the pH of the finishing bath to about 5 with pure acetic acid in the same bath;

[0034] Pre-drying: Send the fabric into the pre-drying device for pre-drying, the pre-drying temperature is 100°C, and the time is 1min;

[0035] Baking: Baking the fabric through a baking machine at a temperature of 125°C for 1.5 minutes;

[0036] Water washing: first use three washing tanks for water washing, the water temperature is 45-60°C, then use one washing tank for warm water washing, the water temperature is 80-85°C, and then use one washing tank for hot water ...

Embodiment 3

[0040] A method for moisture absorption and perspiration finishing of 14.5tex pure cotton poplin, comprising the following steps: gray cloth → padding → pre-baking → baking → washing → drying → shaping → finished product;

[0041] Padding: put the fabric into the rolling tank at room temperature and heat up the water, and at the same time add the finishing agent polysiloxane for padding, the concentration is 60g / L, and adjust the pH of the finishing bath to about 5 with pure acetic acid in the same bath;

[0042] Pre-drying: Send the fabric into the pre-drying device for pre-drying, the pre-drying temperature is 100°C, and the time is 1min;

[0043] Baking: Baking the fabric through a baking machine at a temperature of 130°C for 2 minutes;

[0044] Water washing: first use three washing tanks for water washing, the water temperature is 45-60°C, then use one washing tank for warm water washing, the water temperature is 80-85°C, and then use one washing tank for hot water at 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com