Building anti-continuous collapse reinforcement system and method based on frp fabric

A building and fabric technology, which is applied in building construction, construction, building maintenance, etc., can solve the problems that the strength of reinforcement materials is not fully utilized, the self-weight of the structure and the dead-load bending moment are increased, and it is not suitable for continuous collapse reinforcement. Achieve the effect of improving continuous collapse resistance, improving integrity and avoiding construction damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

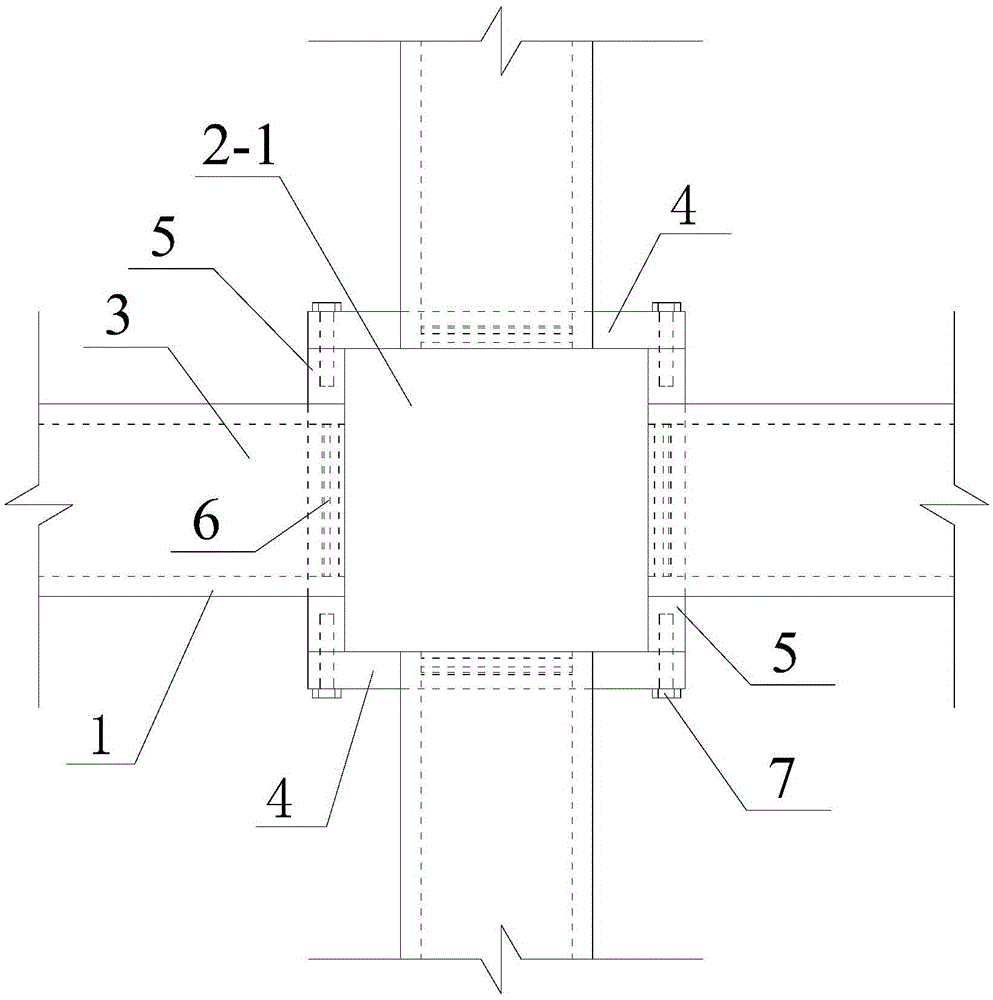

[0057] like figure 1 as well as Figure 5 ~ Figure 8 As shown, the building anti-continuous collapse reinforcement system based on FRP cloth of the present invention includes two first anchor steel plates 4 symmetrically arranged on both sides of the column to be reinforced and symmetrically arranged on the other two sides of the column to be reinforced. The two second anchor steel plates 5 on the surface, and the FRP cloth material 3 pasted on the surface of the beam 1 to be reinforced, the two first anchor steel plates 4 and the two second anchor steel plates 5 are all anchored and connected to the column to be reinforced. A first anchoring steel plate 4 is provided with a first anchor clamp groove 8, and two second anchor steel plates 5 are provided with a second anchor clamp groove 9, and the adjacent first anchor steel plates 4 and the second The anchoring steel plate 5 is fixedly connected by a bolt 7, the first anchoring steel plate 4 is provided with a first threaded ...

Embodiment 2

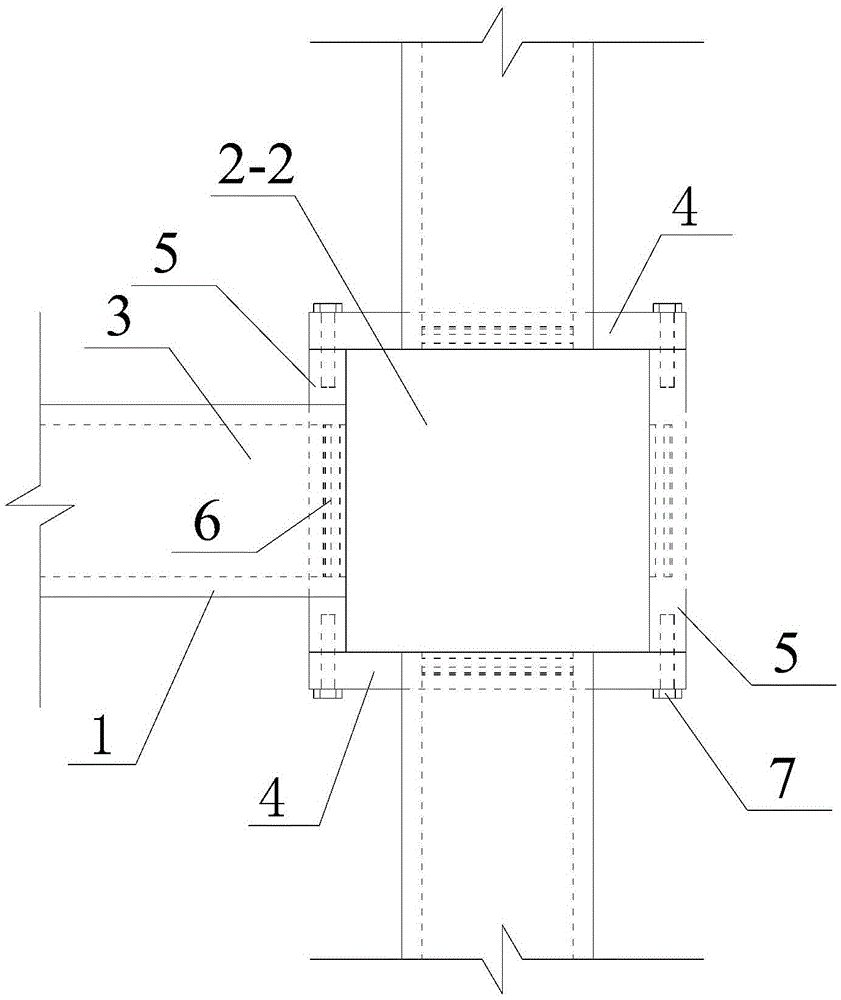

[0064] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the column to be reinforced is a side column 2-2, the number of beams 1 to be reinforced is three, and the corresponding FRP cloth material 3 and anchor clip 6 The quantity is three, wherein two of the anchor clips 6 are fixedly connected in the first anchor clip groove 8, and the other anchor clip 6 is fixedly connected in the second anchor clip groove 9 middle. All the other structures are the same as in Example 1.

Embodiment 3

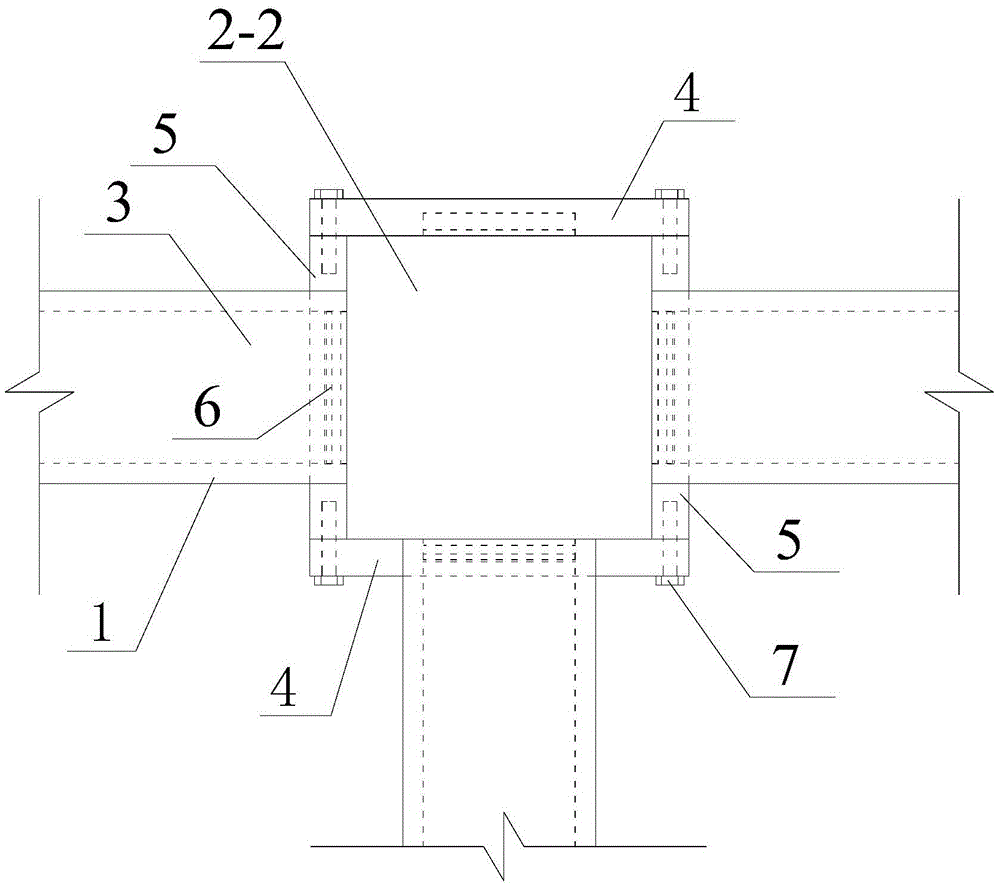

[0066] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that the column to be reinforced is a side column 2-2, the number of beams 1 to be reinforced is three, and the corresponding FRP cloth material 3 and anchor clip 6 The quantity is three, wherein two anchor clips 6 are fixedly connected in the second anchor clip groove 9, and the other anchor clip 6 is fixedly connected in the first anchor clip groove 8 middle. All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com