Dual-vortex negative pressure internal combustion engine

A technology of internal combustion engine and double scroll, applied in the direction of machine/engine, gas turbine device, mechanical equipment, etc., can solve the problems of unreasonable structure and device, and achieve the effect of simple and reasonable structure, saving mechanical loss and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

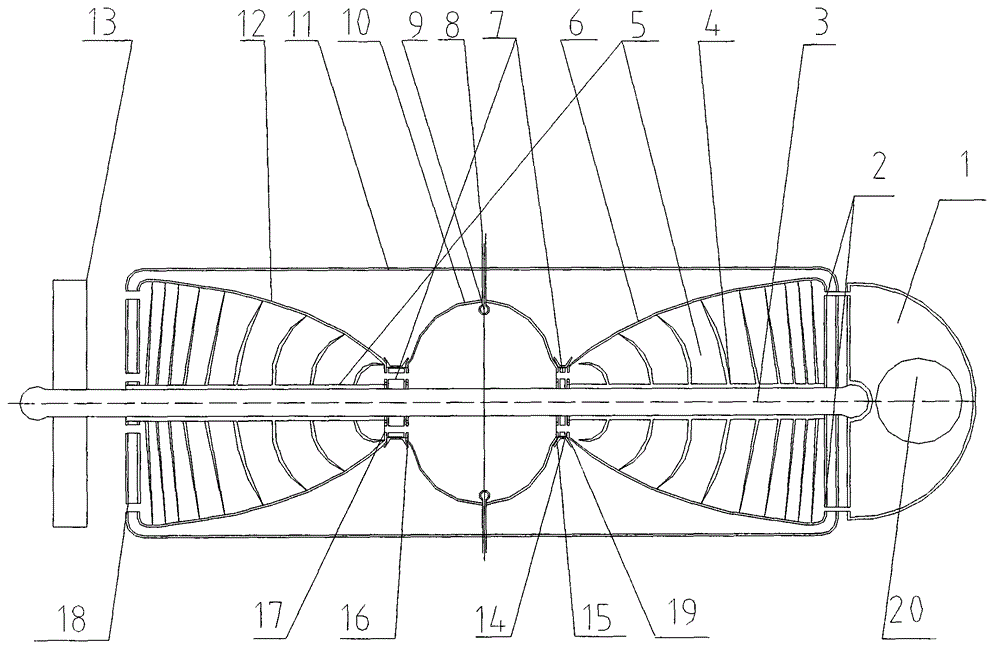

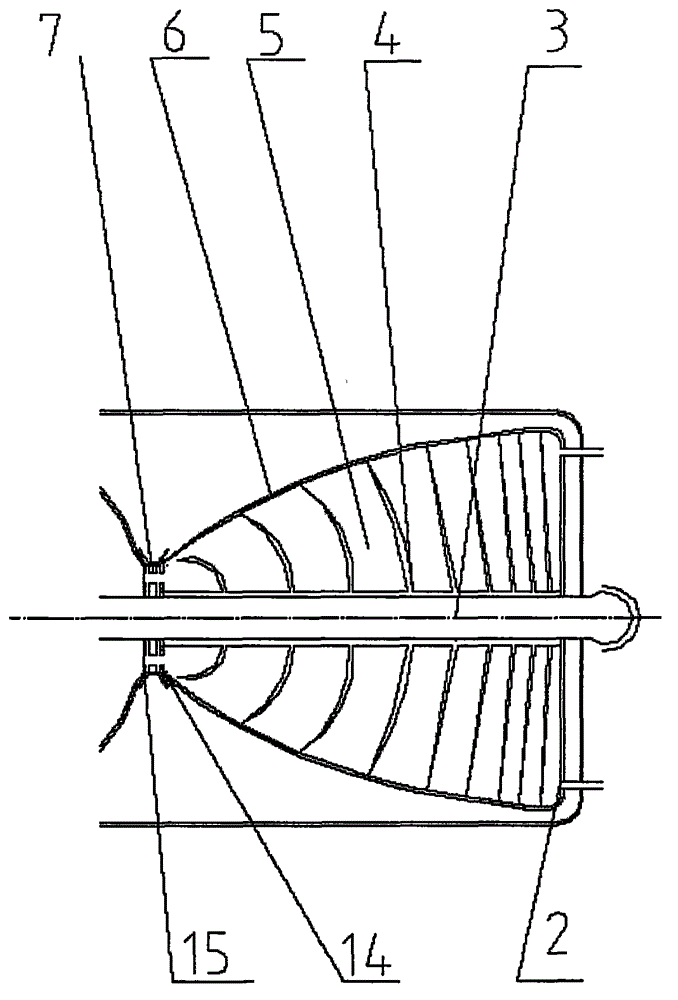

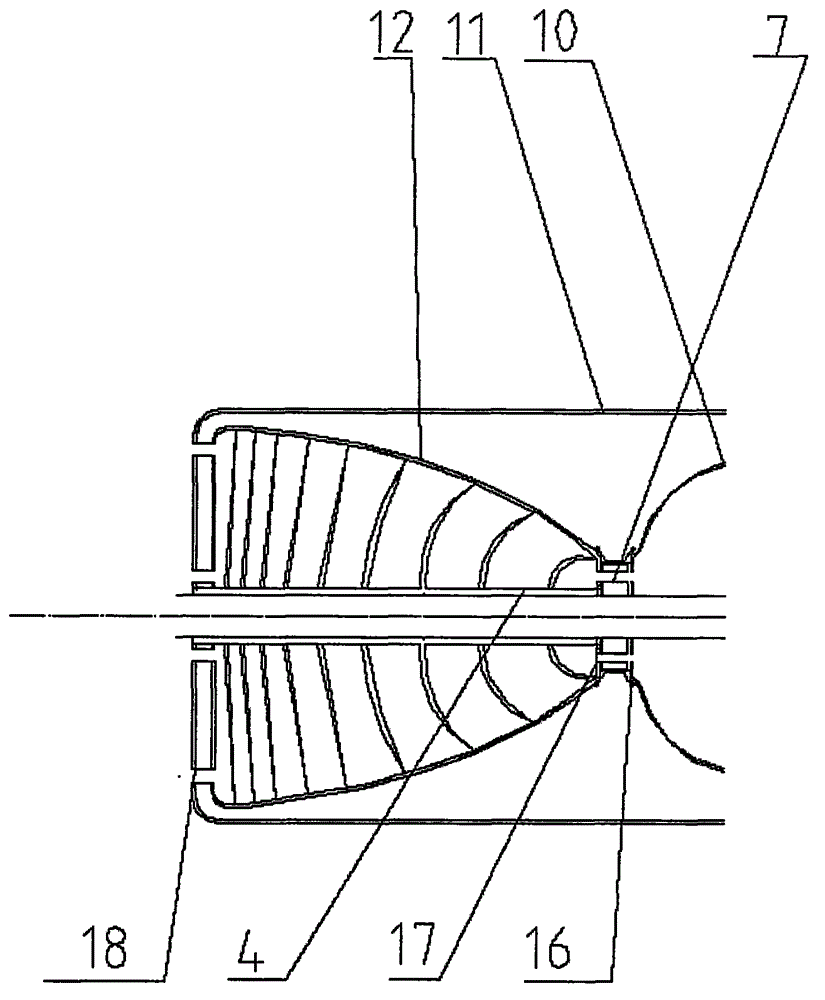

[0037] see Figure 1-7 , In the embodiment of the present invention, a twin-scroll negative pressure internal combustion engine starts from two aspects: first, the expansion of the working principle; second, the innovation of the structure.

[0038]1. Expansion of working principle;

[0039] (1) In the working principle of the present invention, the traditional four-program control work, that is, compression-combustion-expansion work-exhaust, has hardly changed for more than one hundred years, and the main feature of its combustion chamber: normal temperature before the explosion point Atmospheric pressure and constant density (P 0 V 0 / T 0 ) environment work, thermal efficiency in (P 0 V 0 / T 0 ) and (P max V max / T max ), except for the ultra-low temperature where the coolant is artificially used. At present, the application of internal combustion engine working principle has reached the limit and it is difficult to improve.

[0040] (2) The twin-scroll negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com