Preparation method of mercapto carbon nanometer pipe

A technology of carbon nanotubes and mercaptocarbons, which is applied in the field of surface modification of carbon nanotube materials, and can solve problems such as weak van der Waals forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

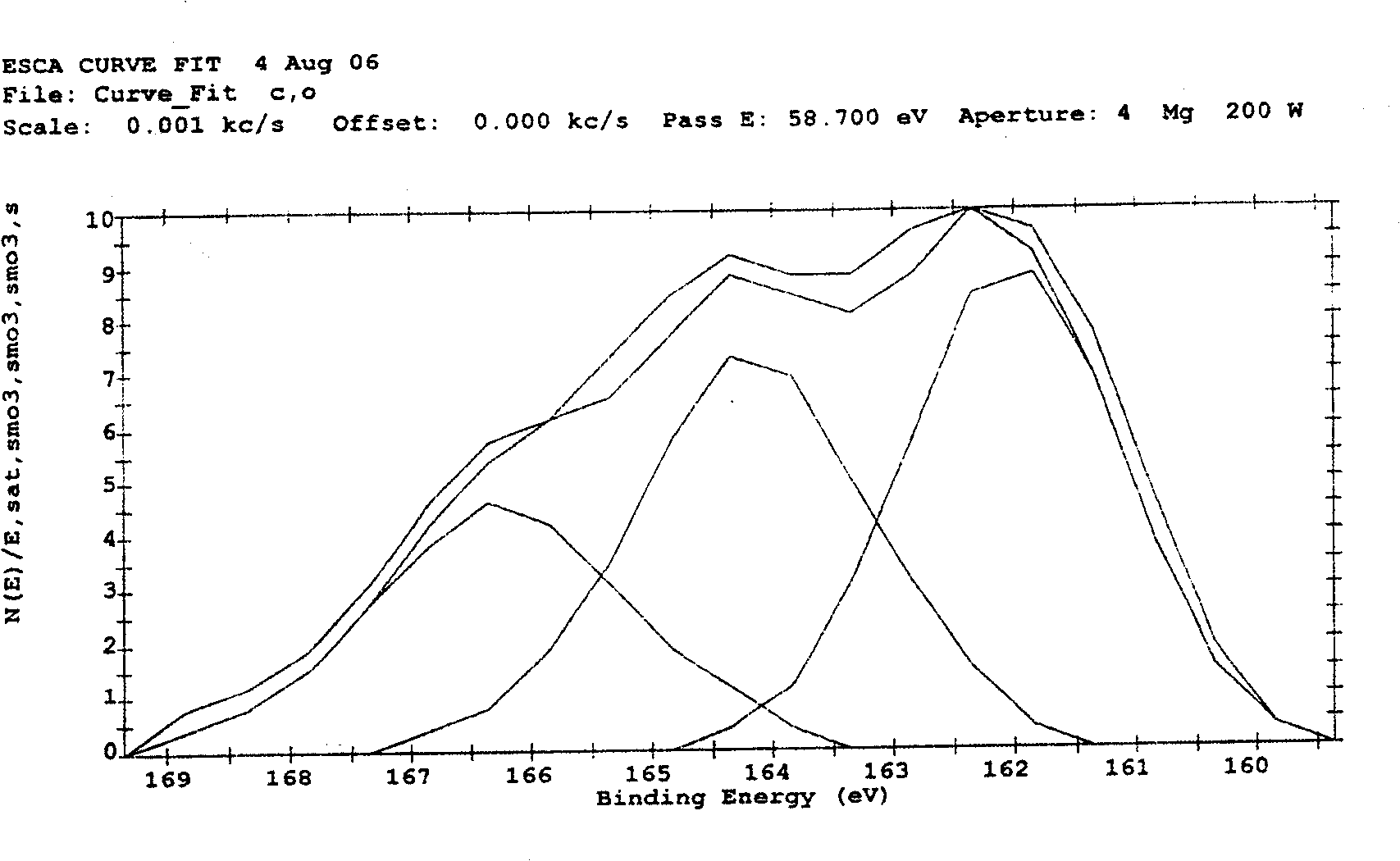

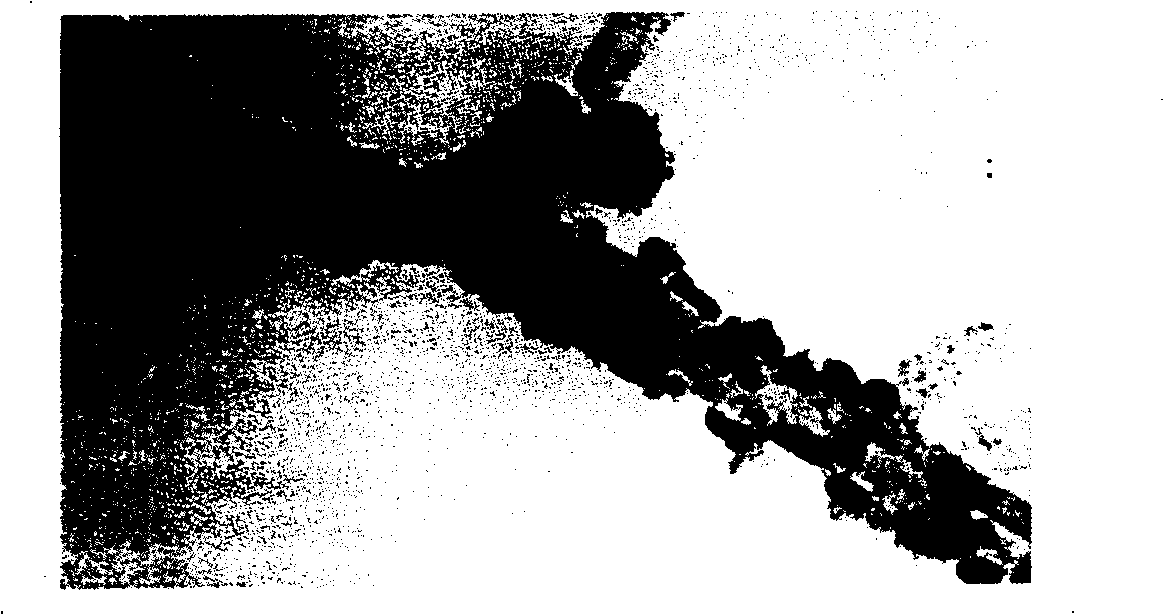

Embodiment 1

[0010] 1) Weigh 0.5 g of multi-walled carbon nanotubes prepared by CVD, add 50 ml of 4:1 (volume ratio) mixed acid of concentrated nitric acid and concentrated sulfuric acid, heat to reflux for 1 h, cool, filter, wash, and dry. The purpose of this step is to attach carboxyl and hydroxyl groups to the surface of the carbon nanotubes.

[0011] 2) Add 0.01mol LiAlH to the carbon nanotubes treated in step 1) 4 In anhydrous ether solution, ultrasonically oscillate for 2min, react in a sealed chamber at room temperature for 1h, filter, wash with anhydrous ether several times until LiAlH is free 4 until it was dried, and then soaked in 0.1M HCl for 30 minutes to allow it to be fully hydrolyzed, and finally filtered, washed, and dried. The purpose of this step is to reduce all the carboxyl groups on the surface of the carbon nanotubes to hydroxyl groups.

[0012] 3) Add 0.02mol / l PBr to the carbon nanotubes after step 2) 3 In anhydrous acetone solution, ultrasonically oscillate for...

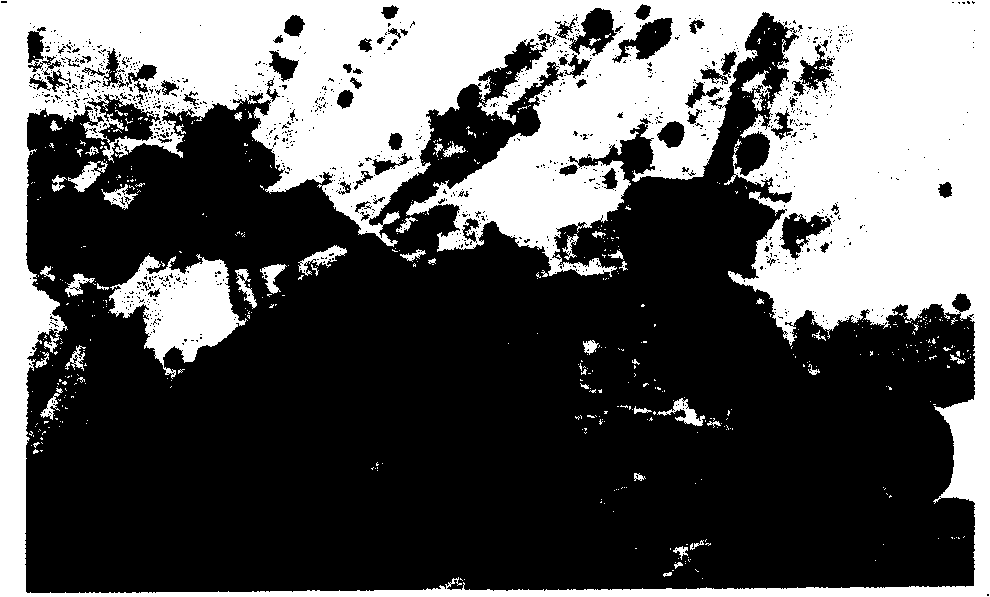

Embodiment 2

[0015] 1) Weigh 0.5 g of single-walled carbon nanotubes prepared by CVD, add 50 ml of 4:1 mixed acid of concentrated nitric acid and concentrated sulfuric acid (volume ratio), heat to reflux for 1 h, cool, filter, wash, and dry. The purpose of this step is to attach carboxyl and hydroxyl groups to the surface of the carbon nanotubes.

[0016] 2) Add 0.01mol LiAlH to the carbon nanotubes treated in step 1) 4 In anhydrous ether solution, ultrasonically oscillate for 2min, react in a sealed chamber at room temperature for 1h, filter, wash with anhydrous ether several times until LiAlH is free 4 until it was dried, and then soaked in 0.1M HCl for 30 minutes to allow it to be fully hydrolyzed, and finally filtered, washed, and dried. The purpose of this step is to reduce all the carboxyl groups on the surface of the carbon nanotubes to hydroxyl groups.

[0017] 3) Add the carbon nanotubes treated in step 2) into a chloroform solution of 0.02 mol / l thionyl chloride, ultrasonically...

Embodiment 3

[0020] 1) Weigh 0.5 g of multi-walled carbon nanotubes prepared by CVD, add 50 ml of 4:1 mixed acid of concentrated nitric acid and concentrated sulfuric acid (volume ratio), heat to reflux for 1 h, cool, filter, wash, and dry. The purpose of this step is to attach carboxyl and hydroxyl groups to the surface of the carbon nanotubes.

[0021] 2) Add 0.01mol LiAlH to the carbon nanotubes treated in step 1) 4 In anhydrous ether solution, ultrasonically oscillate for 2min, react in a sealed chamber at room temperature for 1h, filter, wash with anhydrous ether several times until LiAlH is free 4 until it was dried, and then soaked in 0.1M HCl for 30 minutes to allow it to be fully hydrolyzed, and finally filtered, washed, and dried. The purpose of this step is to reduce all the carboxyl groups on the surface of the carbon nanotubes to hydroxyl groups.

[0022] 3) Add 0.02mol / l ZnCl to the carbon nanotubes treated in step 2) 2 In concentrated hydrochloric acid, ultrasonically osc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com