LED free-form curved face lens used for optical microscope illumination system

An optical microscope and lighting system technology, which is applied to the components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of unfixed lighting distance, inability to obtain effects, and different LED luminous characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

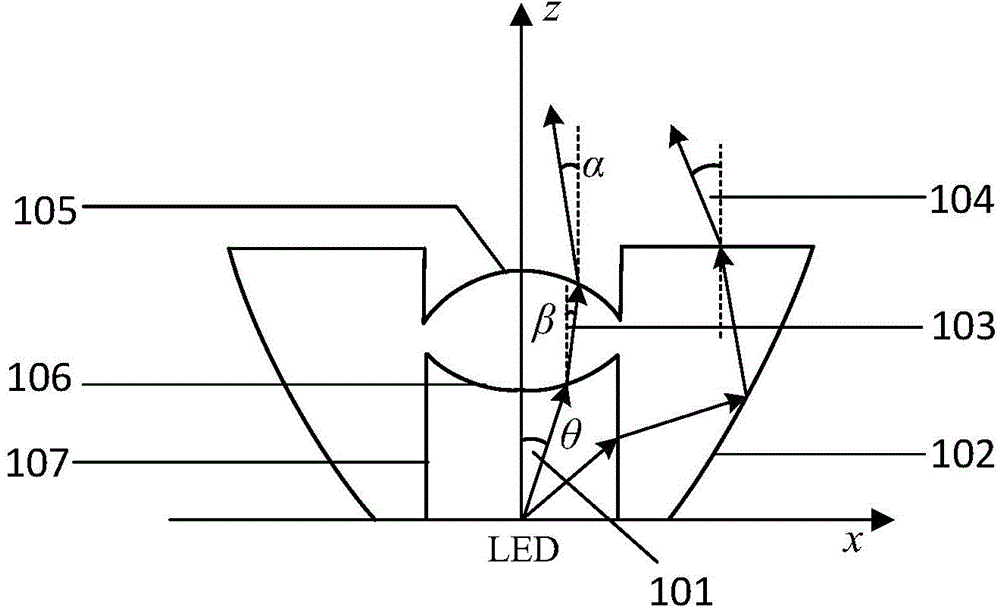

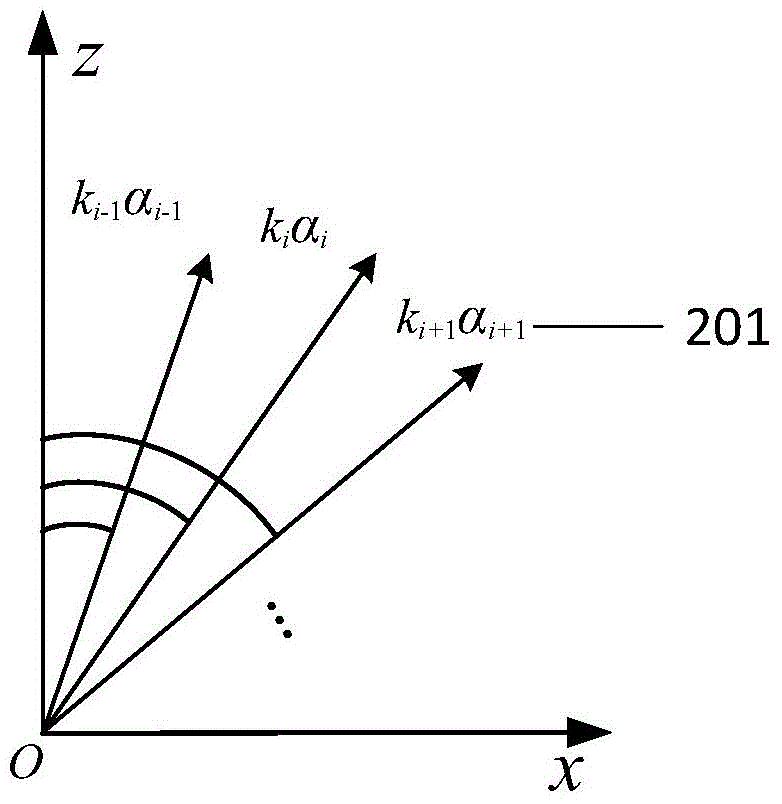

[0075] 1. Set the initial conditions and divide the solid angle of the LED light source.

[0076] First, the distance between the target lighting surface and the LED is 200mm, the target lighting area is a circular area, its radius is R=20mm, the total luminous flux of the LED light source is Φ=100lm, and the central light intensity is I 0 =100 / πcd, the average illuminance of the target lighting area is In the coordinate system, θ is the angle between the incident light and the positive direction of the Z axis, and its value range is α is the angle between the outgoing light and the positive direction of the Z axis, and its value range is The refractive index of the lens material is n=1.49386.

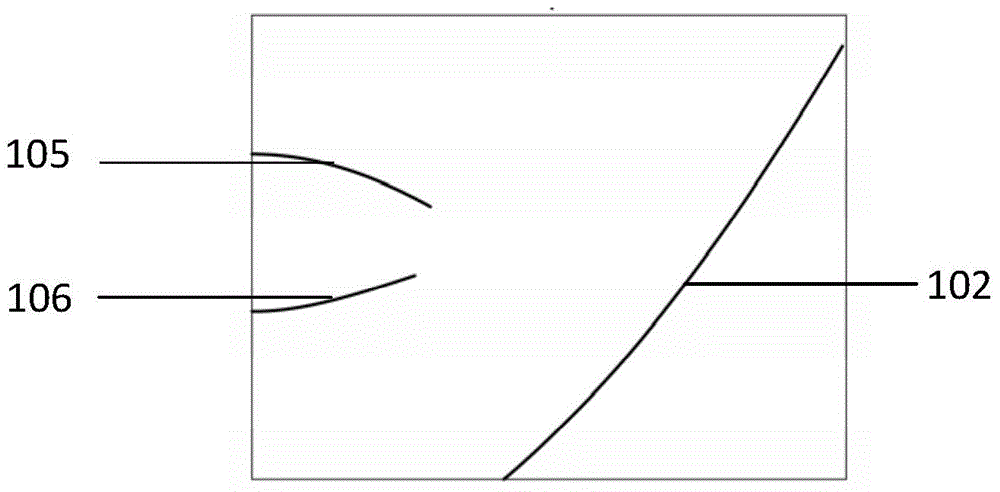

[0077] For the free-form surface inside the lens cavity, its main function is to control the exit angle of light. Here set the angle value range of its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com