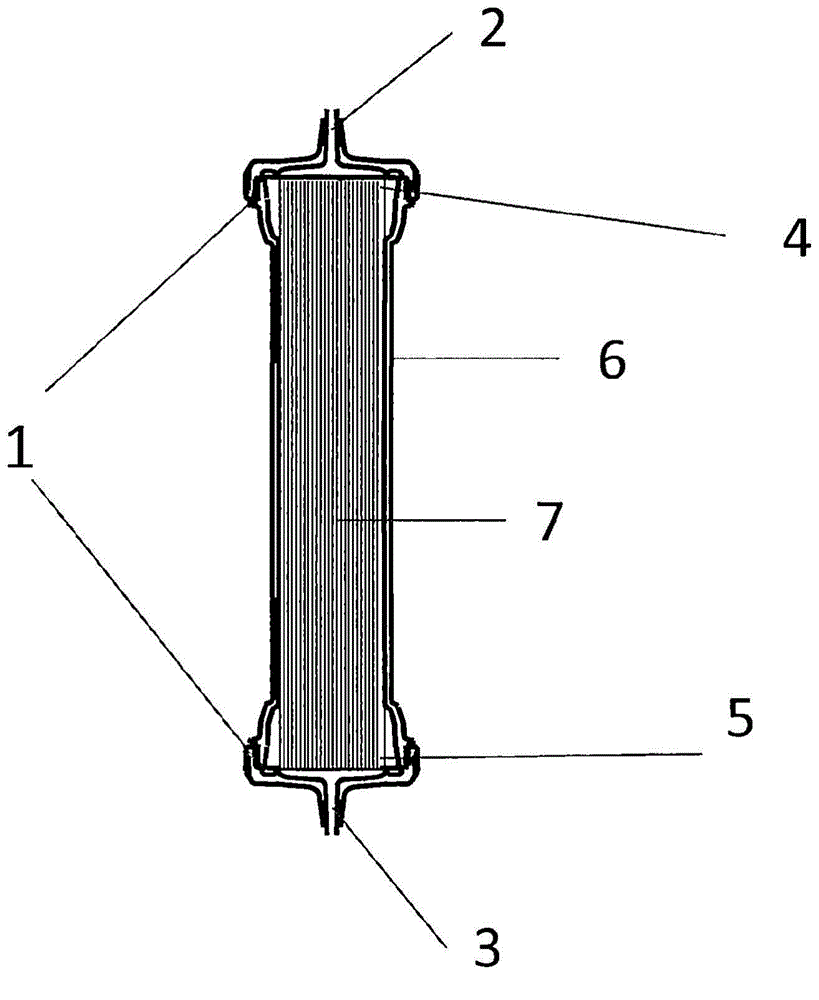

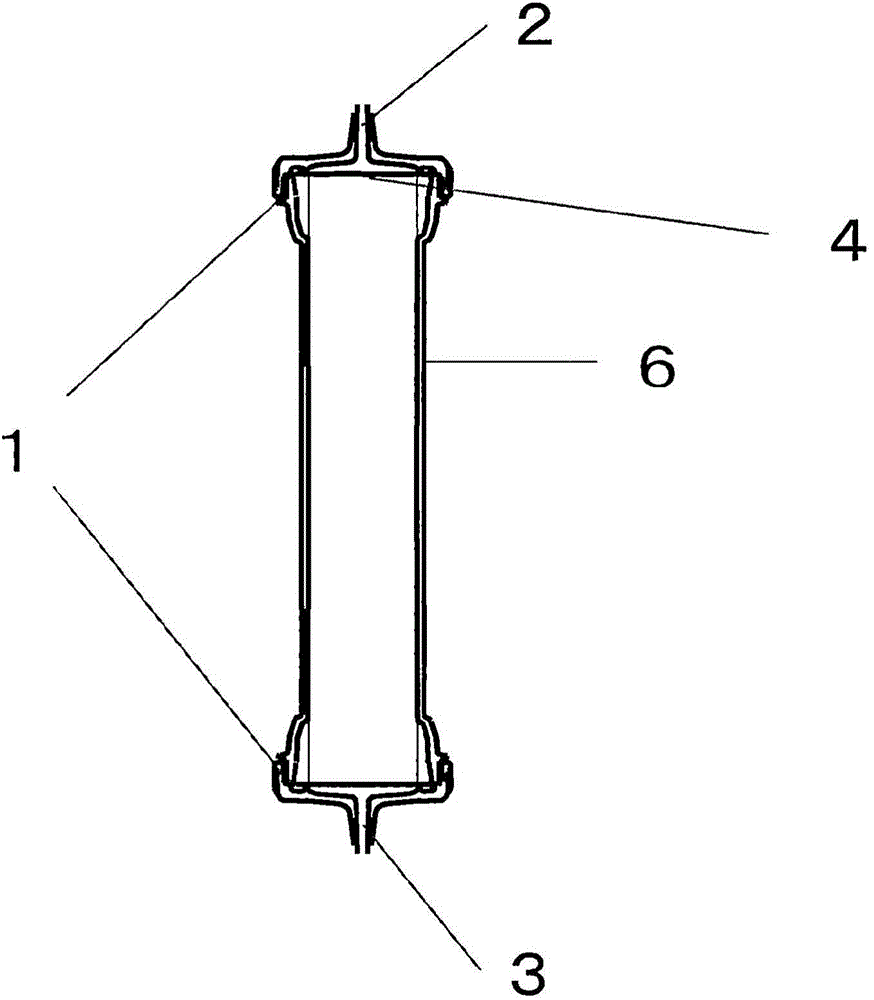

Blood purification column

A blood purification and blood technology, applied in the field of columns, can solve the problems of no exhaust concept and unsatisfactory exhaust, and achieve the effect of improving exhaust and not easy to coagulate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

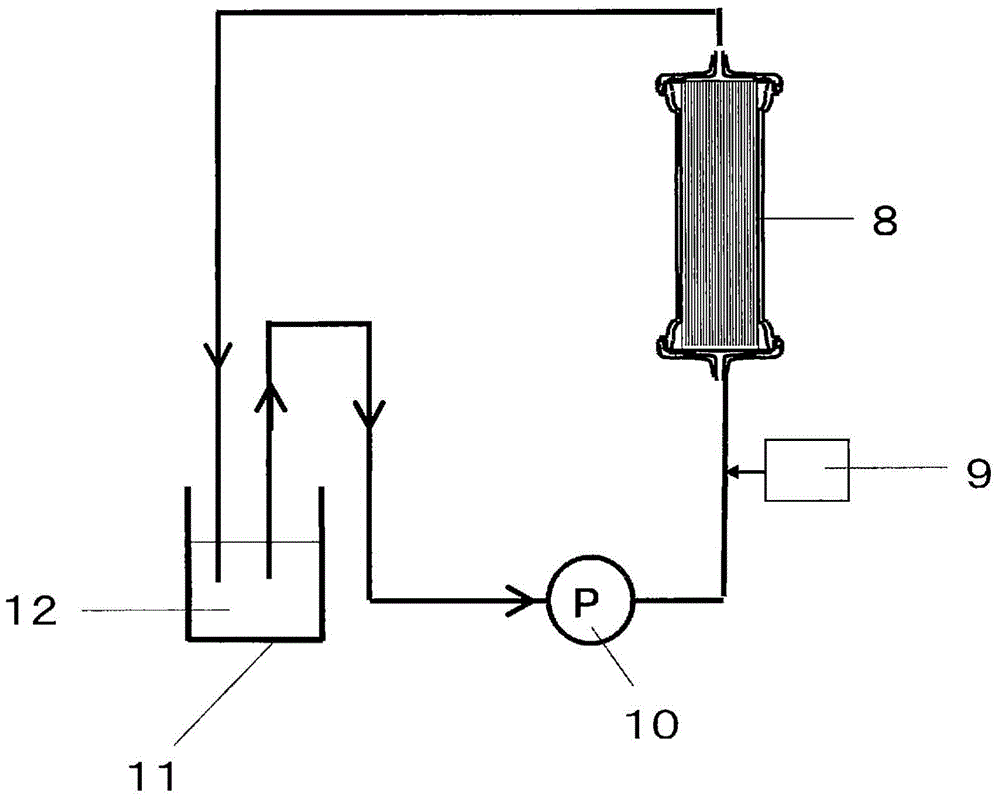

Method used

Image

Examples

Embodiment 1

[0082] 31.7 parts by weight of syn-PMMA with a weight average molecular weight of 400,000, 31.7 parts by weight of syn-PMMA with a weight average molecular weight of 1.4 million, and 16.7 parts by weight of iso-PMMA with a weight average molecular weight of 500,000, containing 1.5 mol% 20 parts by weight of the PMMA copolymer with a molecular weight of 300,000 sodium p-styrene sulfonate was mixed with 376 parts by weight of dimethyl sulfoxide, and stirred at 110° C. for 8 hours to prepare a spinning dope. The obtained spinning dope had a viscosity of 1240 poise at 110°C. The obtained spinning dope was ejected into the air at a rate of 1.0 g / min from a nozzle (having a circular outlet with a diameter of 0.3 mm) kept at 93° C., and the air part was moved for 50 cm before being introduced into a coagulation bath. The water temperature (coagulation bath temperature) used in the coagulation bath was set at 42° C. to obtain a solid yarn. After each solid yarn was washed with water,...

Embodiment 2

[0094] Except that the ejection speed of the spinning stock solution was set at 1.9 g / min so that the filament diameter was 181 μm, a solid filament was obtained by the same method as in Example 1, and it was built in the same size as Example 1 in the same manner as in Example 1. In the casing with the same shape and the same shape, the screen filter and the head cap with the same size and shape as in Example 1 are arranged on both sides of the casing. The average circle-equivalent diameter of the adsorbent gap in this column was 135 μm. For this column, the air removal rate in the column was measured in the same procedure as in Example 1. The results are shown in Table 1.

Embodiment 3

[0096] Except that the ejection speed of the spinning dope was set at 0.5 g / min so that the filament diameter was 56 μm, a solid filament was obtained by the same method as in Example 1, and it was built in the same size as in Example 1 as in Example 1. In the casing with the same shape and the same shape, the screen filter and the head cap with the same size and shape as in Example 1 are arranged on both sides of the casing. The average circle-equivalent diameter of the adsorbent gaps in this column was 42 μm. For this column, the air removal rate in the column was measured in the same procedure as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com