Inner support expansion fixture and cutting technology of ultra-thin wall large-scale cylinder type cutting workpiece

A technology of large-scale cylinder and expansion fixture, which is applied in the direction of expanding the mandrel, etc., which can solve the problem that the cutting accuracy cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

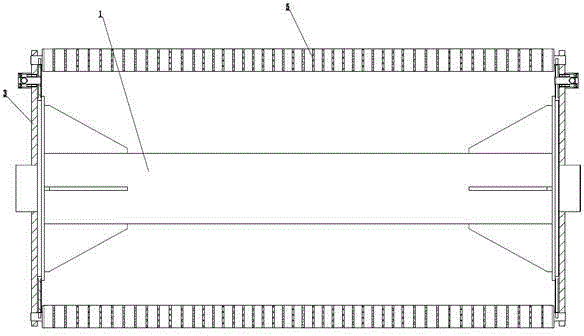

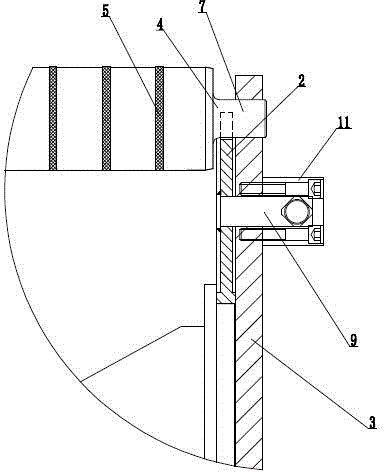

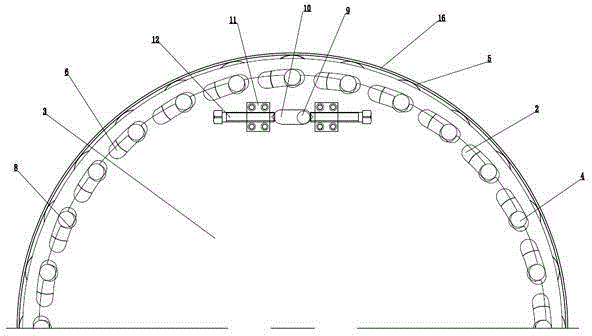

[0028] Such as Figure 1-3 As shown, an inner support expansion fixture for an ultra-thin-walled large-scale cylindrical cutting workpiece provided in this embodiment, the specification size of the ultra-thin-walled large-scale cylindrical cutting workpiece is D / δ=1681.2 / 6.4= 262.69, the above-mentioned internal support expansion fixture includes:

[0029] The central axis 1, the length of the central axis 1 is slightly longer than the length of the above-mentioned ultra-thin-walled large cylindrical cutting workpiece, generally 200-300mm longer than the part;

[0030] The dial wheels 2 on both sides of the central shaft 1 are independently movable and socketed, and the cam plate 3 and the central shaft end plate are fastened with bolts, and the dial wheel 2 and the cam plate 3 on one side of the shaft end are in the same position. The limit is fixed in the direction of the central axis 1 axis;

[0031] Twenty-eight idler rollers 4 are evenly distributed in a circular shape ...

Embodiment 2

[0037] The internal support expansion fixture of an ultra-thin-walled large-scale cylindrical cutting workpiece provided in this embodiment has a general structure consistent with that of Embodiment 1, as shown in Figure 4 As shown, however, in this embodiment, two ratchets 13 are fixedly sleeved on the central shaft 1, and the curvature of the tooth surface of each ratchet 13 is consistent with the curvature of the middle portion of the first elongated hole 6, And it is in contact with the roller surface of each supporting roller 4 all the time.

[0038] The above-mentioned ratchet 13 added on the central shaft 1 can further increase the radial support force of the central shaft 1 to a plurality of idlers 4 (the middle part in the axial direction), and improve the overall structural stability of the inner support expansion clamp .

Embodiment 3

[0040] The internal support expansion fixture of an ultra-thin-walled large-scale cylindrical cutting workpiece provided in this embodiment has a general structure consistent with that of Embodiment 1, as shown in Figure 5 As shown, however, the drive mechanism described in the present embodiment includes: a pair of dials 2 are added dial threaded rods 14, each dial threaded rod 14 is screwed with a locking sleeve 15, The second elongated hole 10 provided in the horizontal direction on the cam plate 3 corresponding to each dial threaded rod 14, wherein each of the above-mentioned dial threaded rods 14 all passes through its corresponding second elongated hole 10, and the lock The tight sleeves 15 are all positioned at the outside of the cam plate 3, and the position is limited by tightening the locking sleeves 15 after the dial wheel threaded rod 14 has adjusted the position of the dial wheel 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com