Sewage treatment device and sewage treatment method

A technology for sewage treatment and facilities, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of convenience, high dissolved oxygen efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

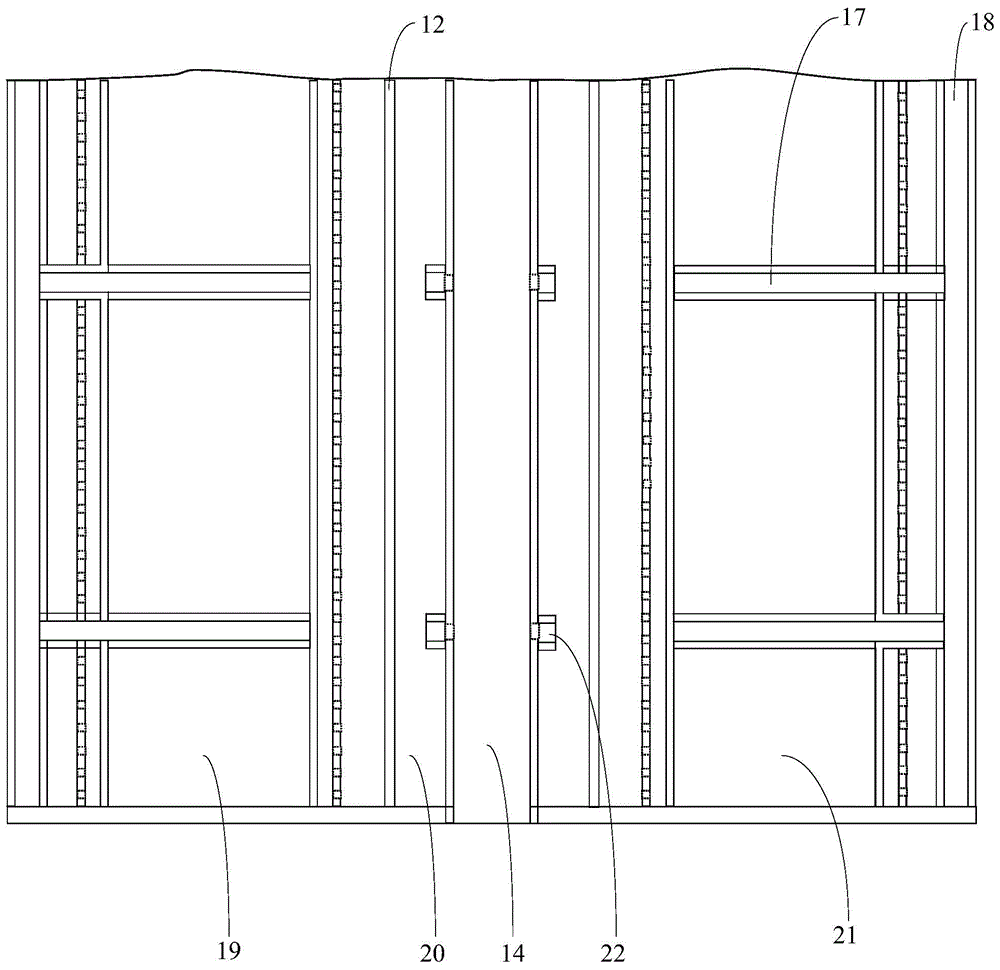

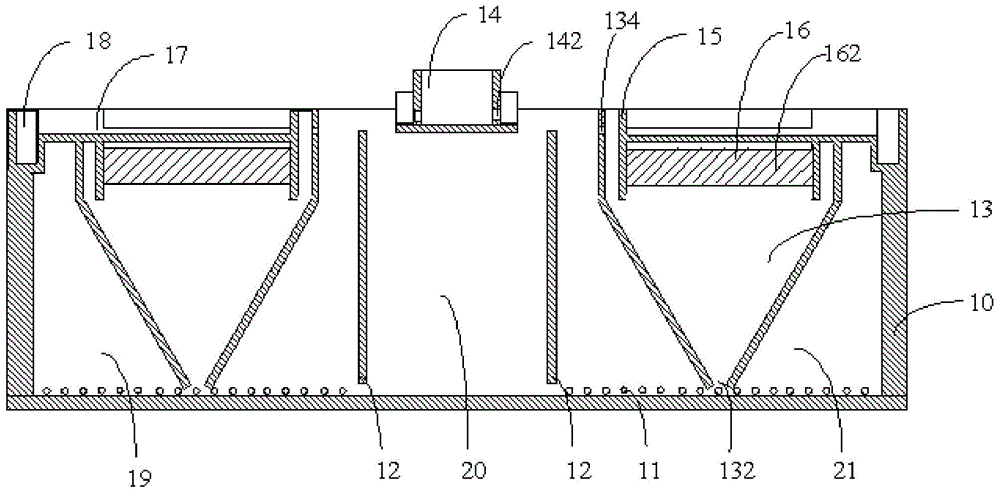

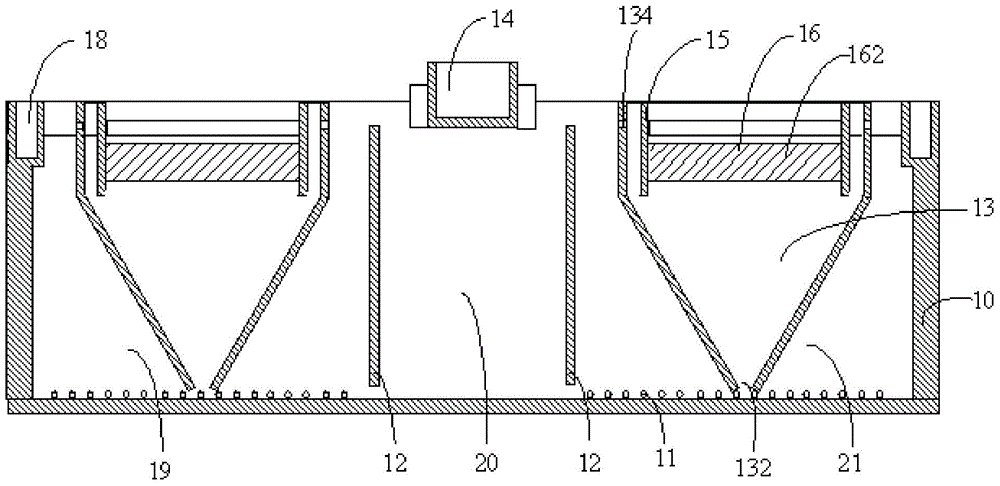

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] figure 1 , figure 2 , image 3 A first embodiment of the invention is shown.

[0034] see figure 1 , figure 2 , image 3 As shown, the sewage treatment facility includes a housing 10 and an aerator 11 arranged on the inner wall of the bottom of the housing 10, and also includes a first deflector 12, a sludge bucket 13, a water distribution channel 14, and a second deflector 15 , settling area 16, overflow tank 17 and clean water tank 18; two first deflectors 12 perpendicular to the bottom surface of the housing 10 are arranged in the middle of the housing 10, and the inner cavity of the housing 10 is divided into the first aerobic reaction zone in turn 19. The anoxic reaction zone 20 and the second aerobic reaction zone 21, and the upper and lower ends of the first deflector 12 are spaced apart from the housing 10; the first aerobic reaction zone 19 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com