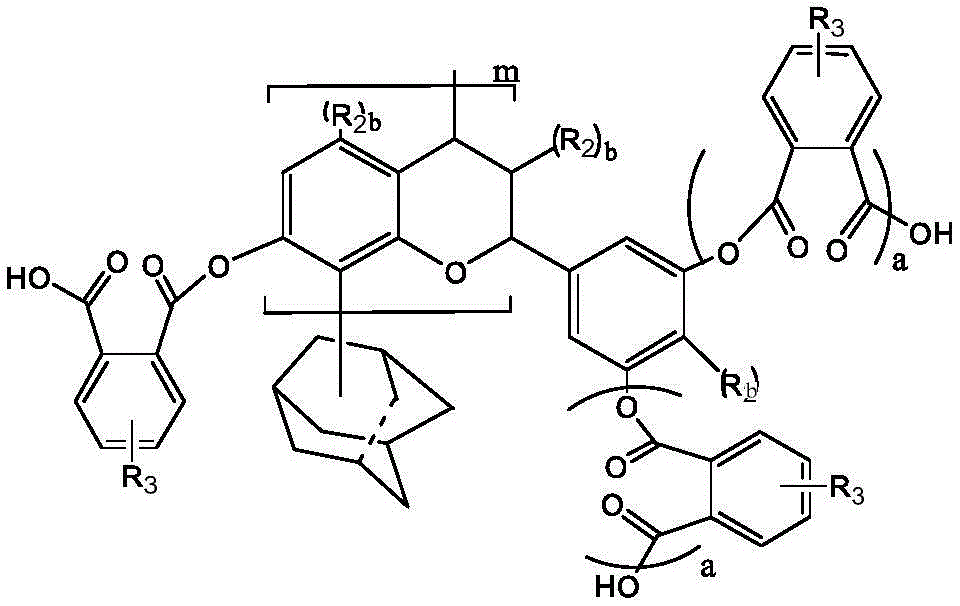

Adamantane based resin composite and preparation method thereof

A technology of resin composition and adamantyl, applied in the direction of organic chemistry, can solve the problems of resin strength reduction, low shrinkage rate, material fracture, etc., and achieve the effect of simple and easy reaction, mild reaction conditions and stable resin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

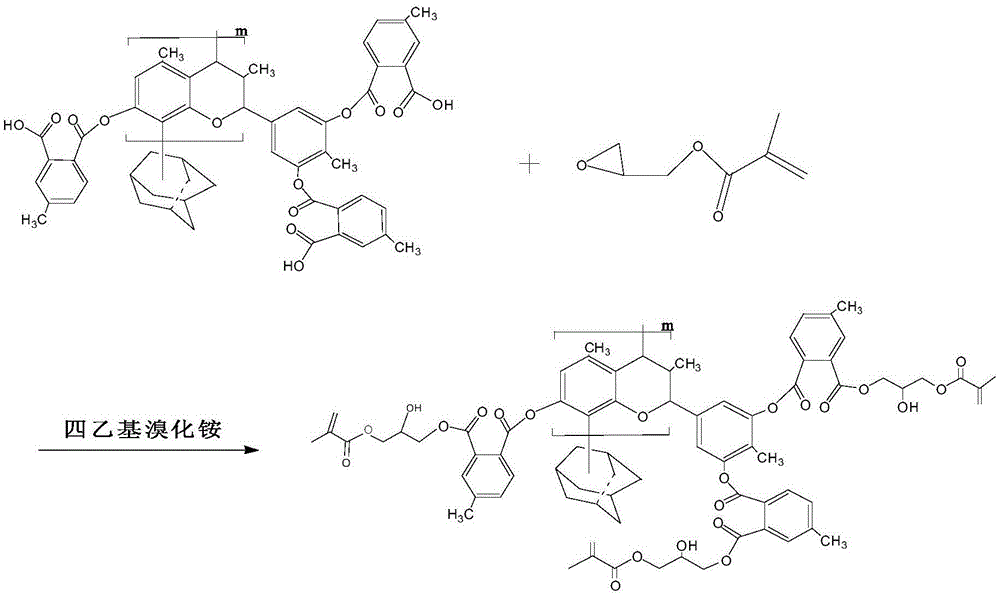

Method used

Image

Examples

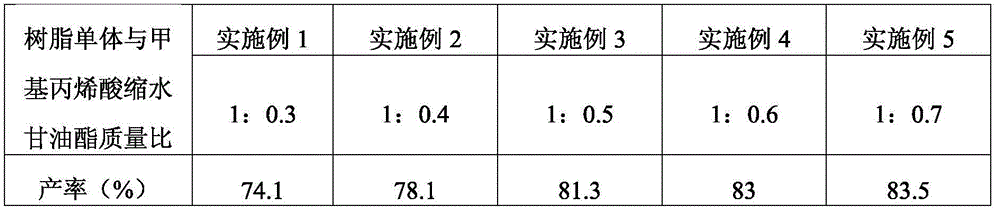

example 1

[0030] Mix 20g of resin monomer and 6g of glycidyl methacrylate in a three-necked flask, add 1.6g of catalyst tetraethylammonium bromide and 0.6g of polymerization inhibitor benzoquinone, react at 135°C for 8.5 hours, use hot water The product was washed and filtered under reduced pressure to obtain a resin composition with a yield of 74.1%.

[0031]

example 2

[0033] Mix 20g of resin monomer A and 8g of glycidyl methacrylate in a three-necked flask, add 1.6g of catalyst tetraethylammonium bromide and 0.6g of benzoquinone as a polymerization inhibitor, and react at 135°C for 8.5 hours. The product was washed with water and filtered under reduced pressure to obtain a resin composition with a yield of 78.1%.

example 3

[0035] Mix 20g of resin monomer A and 10g of glycidyl methacrylate in a three-necked flask, add catalyst tetraethylammonium bromide 1.6g and polymerization inhibitor benzoquinone 0.6g, react at 135°C for 8.5 hours, use heat The product was washed with water and filtered under reduced pressure to obtain a resin composition with a yield of 81.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com