Medical dextrose monohydrate production technology

A production process and glucose technology, applied in the field of glucose processing technology, can solve the problems of environmental pollution, high production cost and waste liquid, and achieve the effects of simple process, high utilization rate and less amount of enzyme added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

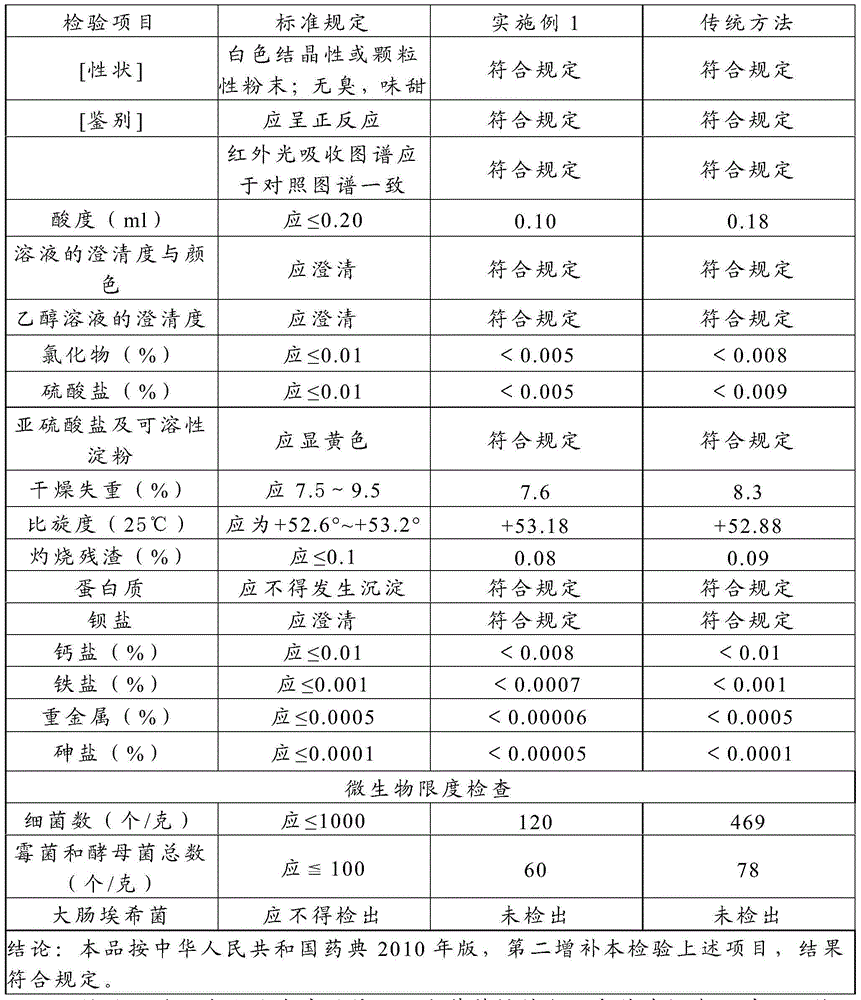

Embodiment 1

[0030] Example 1: First, add cornstarch milk and liquefaction enzyme equivalent to 1 / 3 volume of cornstarch milk to the batching tank at the same time. During the addition process, the batching tank should gradually heat up. When the temperature rises to 110 ° C, keep the temperature and maintain 1 minute (in order to fully mix the corn starch and liquefaction enzyme, the flow of corn starch milk and liquefaction enzyme should be controlled when adding, after a lot of tests, it was found that the flow of corn starch milk was kept at 99169Kg / h, and the flow of liquefaction enzyme was kept at 5.0L / h can make cornstarch milk and liquefaction enzyme fully. Considering that the activity of common enzymes decreases with the increase of temperature, the decrease of enzyme activity will bring two hazards. One is to affect the hydrolysis effect, and the other is to It is to increase the consumption of enzyme in production, so use high temperature resistant liquefaction enzyme in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com