Dechlorination method of iron cultural relics

A cultural relic and dechlorination technology, applied in the field of dechlorination of ferrous cultural relics, can solve the problems of insufficient dechlorination, long dechlorination cycle of ferrous cultural relics, corrosion in the dechlorination process, etc., which is beneficial to the preservation of cultural relics and solves the problem of continued corrosion , the effect of stabilizing rust products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

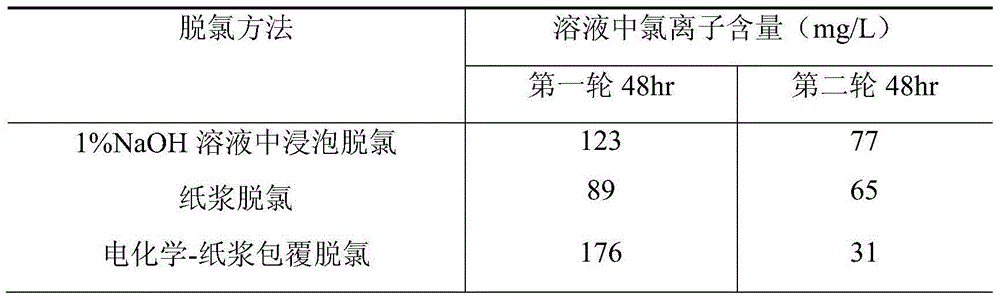

Examples

Embodiment 1

[0033] The cultural relic to be dechlorinated is a cylindrical unearthed iron component with a length of 16 cm and a diameter of about 3 cm. It is severely corroded and contains chloride after testing. The surface of the iron components has been cleaned to remove floating rust and dirt, and it is ready for dechlorination.

[0034]Prepare raw rice paper, tear it into shreds by hand, soak it in pure water (requiring the conductivity of pure water to be less than 10μS / cm) to prepare pulp. Wash the rice paper and test the conductivity of the water. If the conductivity is higher than 20μS / cm, wring out the pulp, replace it with pure water and wash it again until the conductivity is lower than 20μS / cm, and filter out excess water to obtain pulp. Connect the iron components with copper wires, wrap the pulp on the surface of the cultural relics, squeeze the pulp as much as possible by hand to squeeze out the water. Then wrap the stainless steel wire around the pulp, connect the coppe...

Embodiment 2

[0036] The cultural relics to be dechlorinated are 127mm × 35mm × 149mm iron components salvaged from the seabed, which are severely mineralized and contain high chloride content. After cleaning the surface of the components, they are ready for dechlorination treatment.

[0037] Prepare raw rice paper, tear it into shreds by hand, soak it in pure water (requires the conductivity of pure water to be less than 10μS / cm) and soak it into pulp. Wash the rice paper and test the conductivity of the water. If the conductivity is higher than 20μS / cm, wring out the pulp, replace it with pure water and wash it again until the conductivity is lower than 20μS / cm, and filter out excess water to obtain pulp. Connect the iron components with copper wires, wrap the pulp on the surface of the cultural relics, squeeze the pulp as much as possible by hand to squeeze out the water.

[0038] A low-voltage DC stabilized power supply is used for dechlorination, and a rheostat is used to adjust the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com