Low bath voltage zinc electrolysis method

A technology of electrolytic zinc and low tank, applied in the field of zinc hydrometallurgy, can solve the problems of high tank pressure, high energy consumption, high energy consumption of electrolytic zinc, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

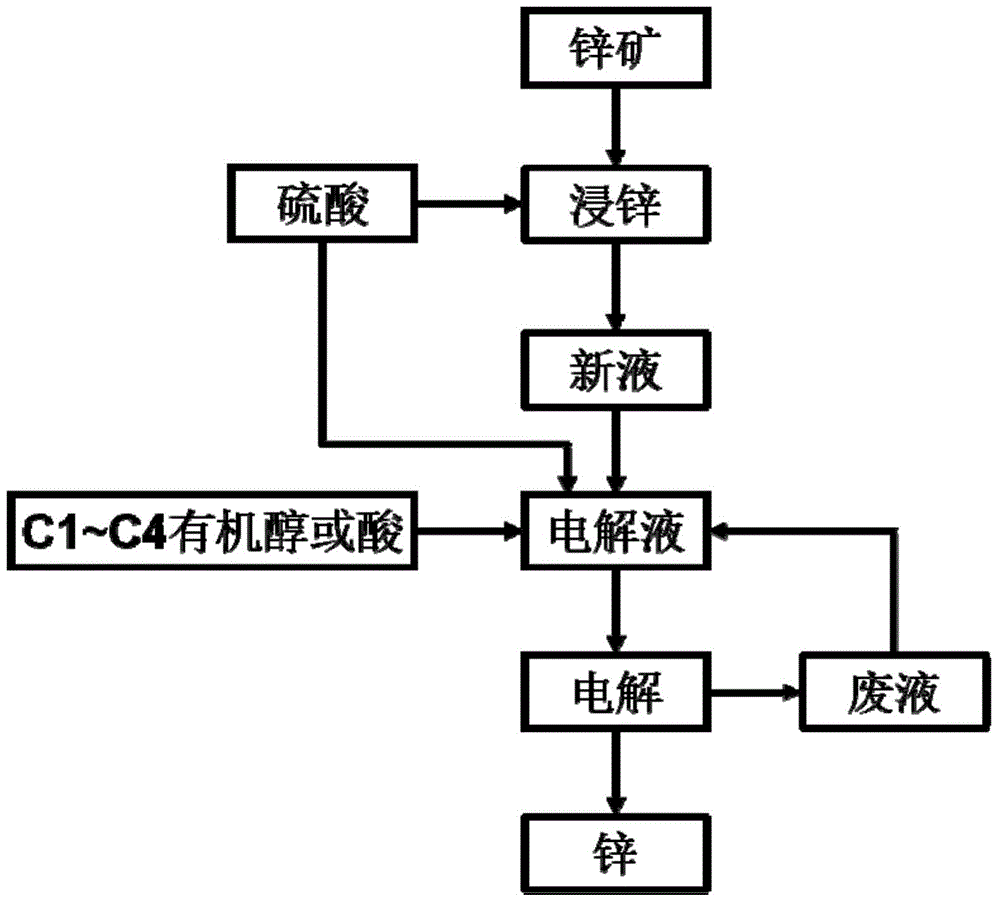

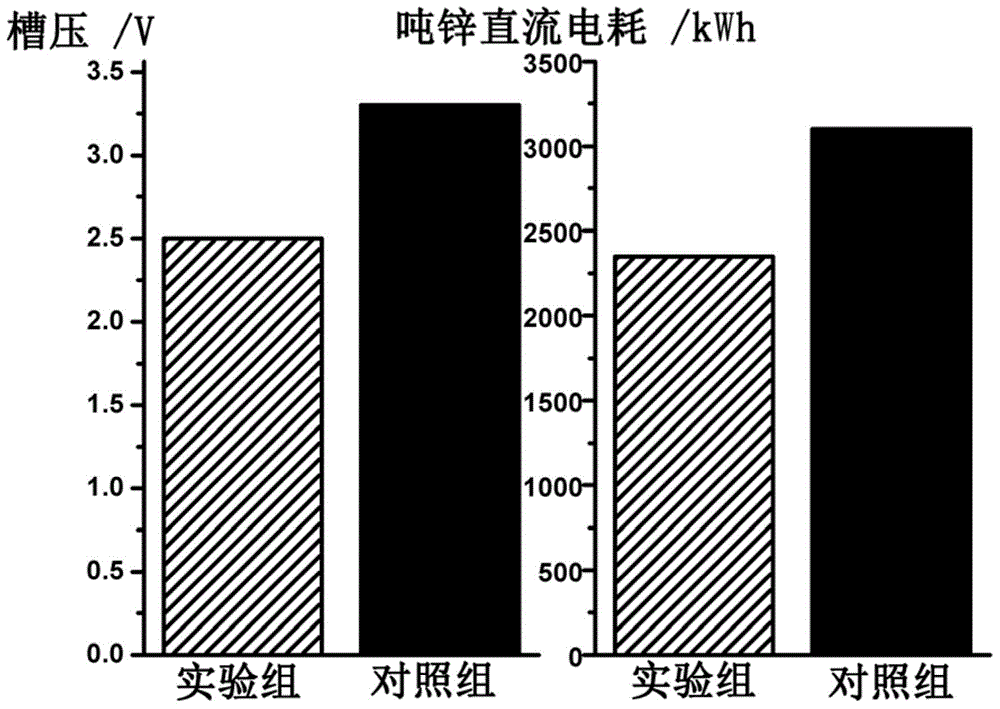

[0032] The new low tank voltage electrolytic zinc method includes the steps of zinc immersion, liquid mixing, electrolysis, and waste liquid control. The specific process is as attached figure 1 The flowchart shown.

[0033] The zinc leaching step is to use dilute sulfuric acid to leach the raw zinc oxide ore, the leached new solution has a zinc content of 70-80 g / L, and the electrolyte solution contains a sulfuric acid content of 150-160 g / L. Purified new solution is required to meet: Cd<0.5mg / L, Cu<0.1mg / L, Co<0.2mg / L, Fe<15mg / L, As<0.01mg / L.

[0034] The mixing step is to mechanically mix the new solution, sulfuric acid and the electrolytic waste solution recycled through the diversion tank in the mixing tank, and add methanol so that the methanol content is 80-100g / L. After physical and mechanical mixing, the final product is obtained. The electrolyte enters the electrolytic cell for electrolytic zinc process.

[0035] The electrolysis step comprises the steps of adoptin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com