Karst water guiding device and method

A karst water and water guiding mechanism technology, applied in construction, infrastructure engineering and other directions, can solve the problems of karst threatening mining safety, increasing mining cost, uneven distribution, etc. The effect of easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

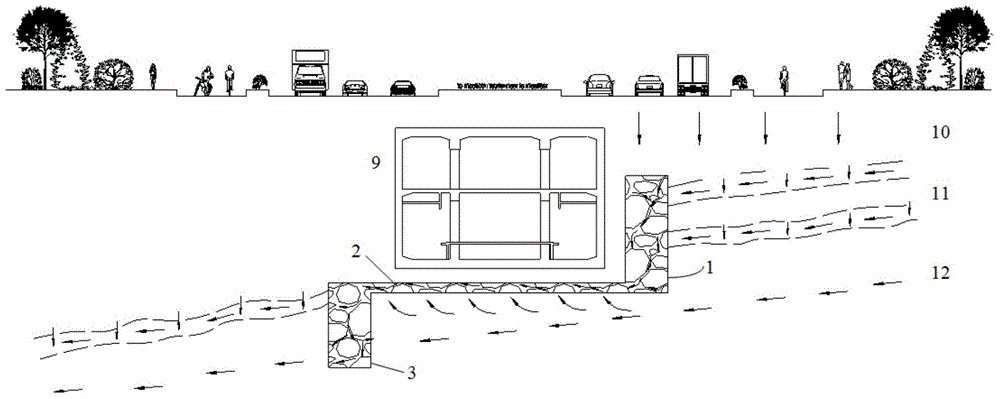

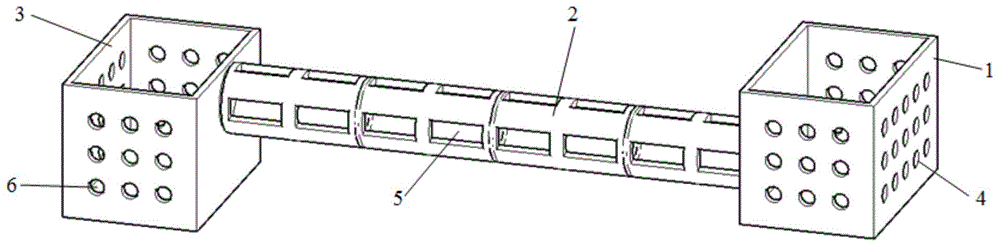

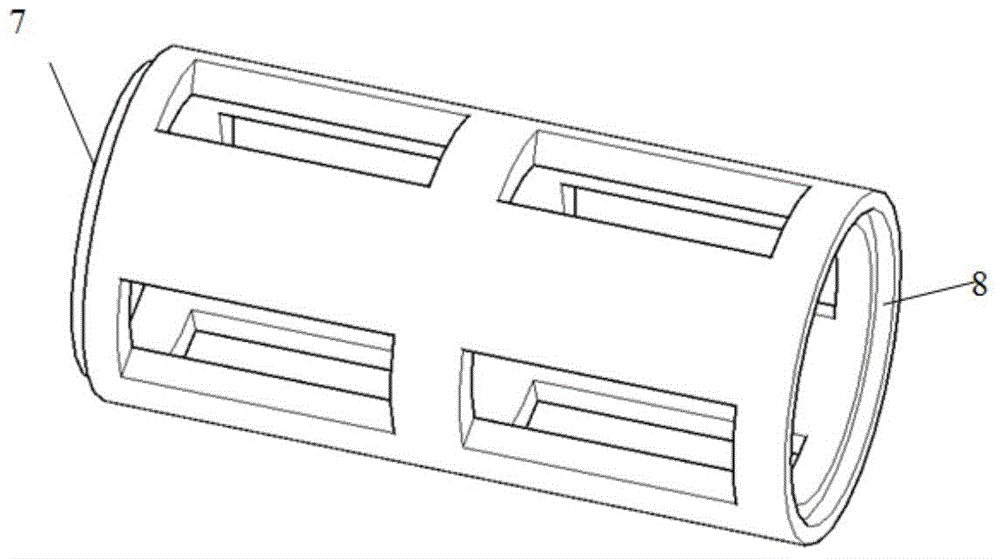

[0036] Such as Figure 1-3 As shown, a karst water guiding device includes a water collecting mechanism 1, a water guiding mechanism 2 and a drainage mechanism 3. The water collecting mechanism 1 is vertically arranged on one side of an underground structure 9, or the water collecting mechanism is relatively horizontal. It is inclined 0°~15° away from the underground building, its top is set between the karst water-entrained zone 10 and the seasonal change zone 11, and its bottom is flush with the bottom of the water guide mechanism, and the water guide mechanism One end is connected with the water collecting mechanism, and the other end is connected with the drainage mechanism. The water guiding mechanism 2 is horizontally arranged under the underground building, and the drainage mechanism is vertically arranged downstream of the karst water channel, or the drainage mechanism is inclined to the horizontal direction. The direction away from the water guiding mechanism is incli...

Embodiment 2

[0051] A karst water guide device, including a water collection mechanism 1, a water guide mechanism 2 and a drainage mechanism 3, the water collection mechanism is vertically arranged on one side of an underground building, and its top is arranged in a karst water-entrained zone and a seasonal change zone Between, the bottom end of which is flush with the bottom end of the water guiding mechanism, one end of the water guiding mechanism is connected with the water collecting mechanism, and the other end is connected with the drainage mechanism 3, and the water guiding mechanism 2 is obliquely arranged in the underground building Below, the inclination direction of the water guiding mechanism follows the flow direction of water in the karst layer, that is, it is higher near the water collecting mechanism and lower near the drainage mechanism. Water belt; the drainage mechanism is vertically arranged under the other side of the underground building, which is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com