Supercharger turbine with water spraying device

A technology of turbocharger turbine and water spray device, which is applied in the direction of muffler, exhaust device, machine/engine, etc. It can solve the problems of difficult control of waste gas bypass flow, slow valve action, complicated pipeline, etc., and achieve simple structure , small throttling loss, and the effect of reducing the exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in more detail below in conjunction with accompanying drawing example:

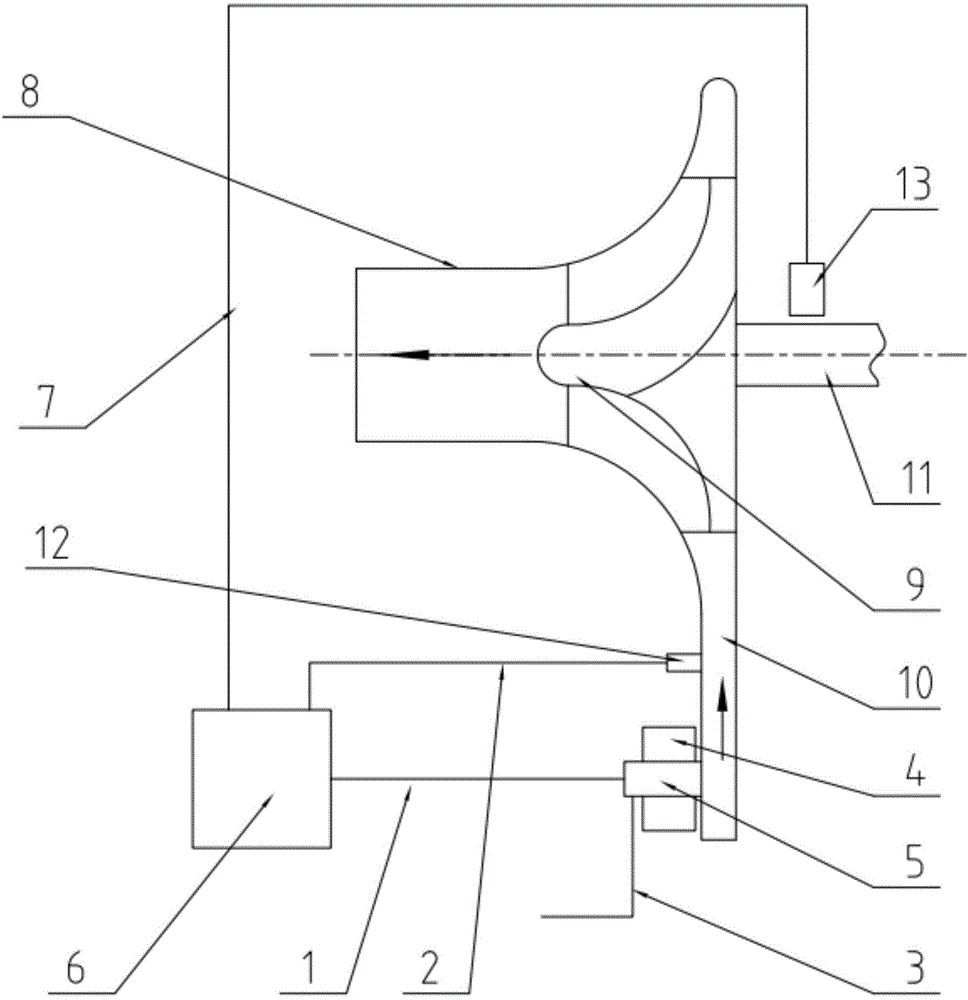

[0011] combine figure 1 , the turbine volute 8 and the turbine inlet 10 are integrated, and the turbine blades 9 and the supercharger shaft 11 are connected together and can rotate in the space formed by the turbine volute 8 . The turbine inlet 10 is equipped with a temperature sensor 12 and a sprinkler 5 , as well as a sprinkler control circuit 1 , a temperature sensor circuit 2 , a sprinkler inlet pipeline 3 , and a cooling water jacket 4 . On the supercharger shaft 11, there is a rotational speed sensor 13 and a supporting rotational speed sensor line 7, and the system central controller 6 is located on the lower left. The main invention is that a water sprayer 5 and temperature Sensor 12, rotational speed sensor 13, and control system, in order to prevent the high temperature of turbine from causing water to be vaporized in advance in the sprinkler, a cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com