Multi-way valve

A technology of multi-way valve and unloading valve, applied in the field of multi-way valve, can solve the problems of disconnection of main engine development, achieve the effect of complete matching, reduce overflow loss and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

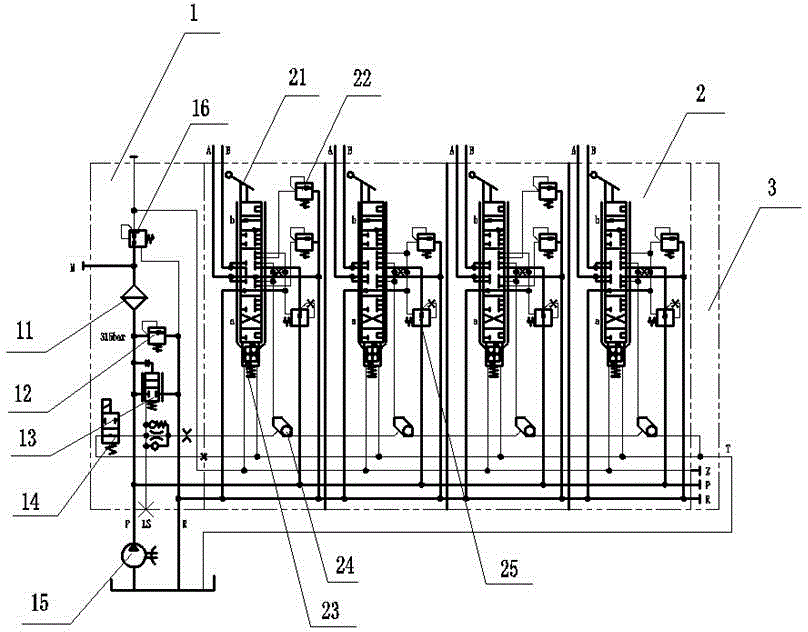

[0016] Such as figure 1 As shown, a multi-way valve includes a connecting block 1, and the connecting block 1 includes a main pressure limiting valve 16, a filter 11, a three-way pressure reducing valve 12, a differential overflow valve 13, an electromagnetic unloading valve 14 and Pump 15, connecting block 1 is connected with reversing block 2, and reversing block 2 includes integral handle seat mechanism 21, secondary pressure limiting valve 22, differential pressure reducing valve 25, shuttle valve 24 and proportional electromagnet 23, said The filter 11 is installed between the main pressure limiting valve 16 and the three-way decompression valve 12, the three-way decompression valve 12 is connected to the differential relief valve 13, the differential relief valve 13 is connected to the pump 15, and the differential relief valve 13 An electromagnetic unloading valve is installed between the valve and the pump, a tail plate is installed behind the reversing block, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com