An ultrasonic c-scan imaging method based on dac curve

A scanning imaging and ultrasonic technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of complex image processing process and unintuitive display of equivalent size, etc., to achieve wide application prospects, facilitate on-site detection, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

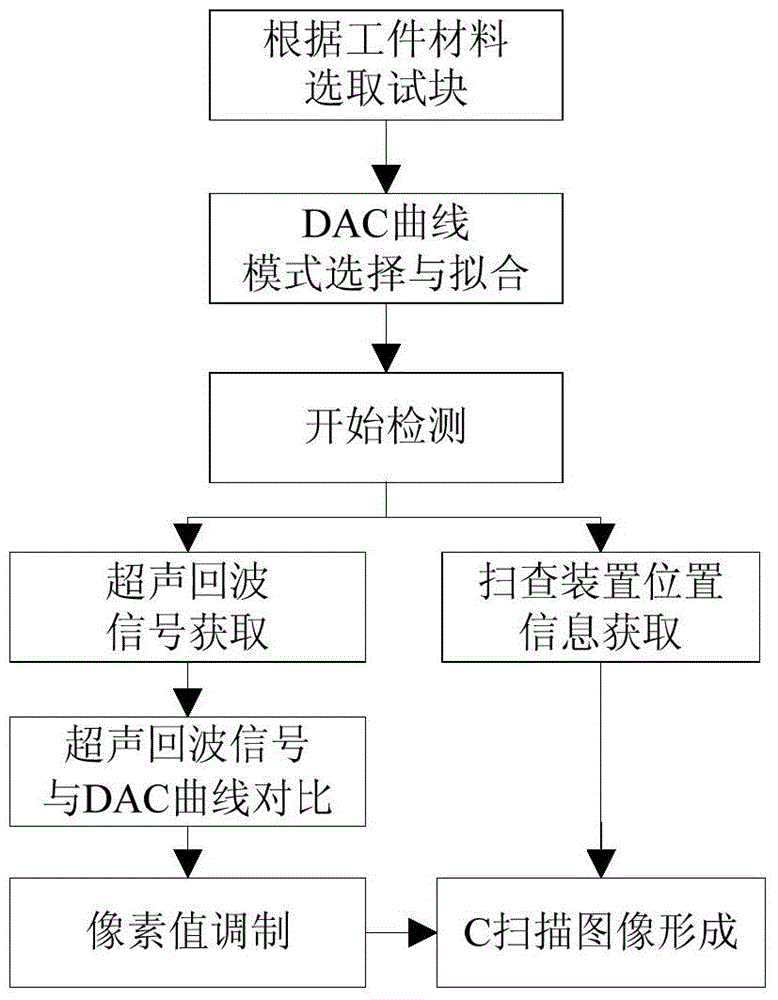

[0028] A kind of ultrasonic C-scan imaging method based on DAC curve, concrete steps are as follows:

[0029] Step 1. Select a test block with the same material as the workpiece to be inspected, and the test block has more than 3 defects with the same aperture and different depths:

[0030] The material of the workpiece to be inspected is aluminum alloy as an example. First, select the test block of aluminum alloy material. The equivalent of the flat-bottomed hole of the test block is 1.2mm, and the flat-bottomed hole is a regular reflector. The flat-bottomed hole has 8 different depths, respectively 2.5mm, 7.5mm, 30mm, 50mm, 70mm, 90mm, 110mm, 120mm.

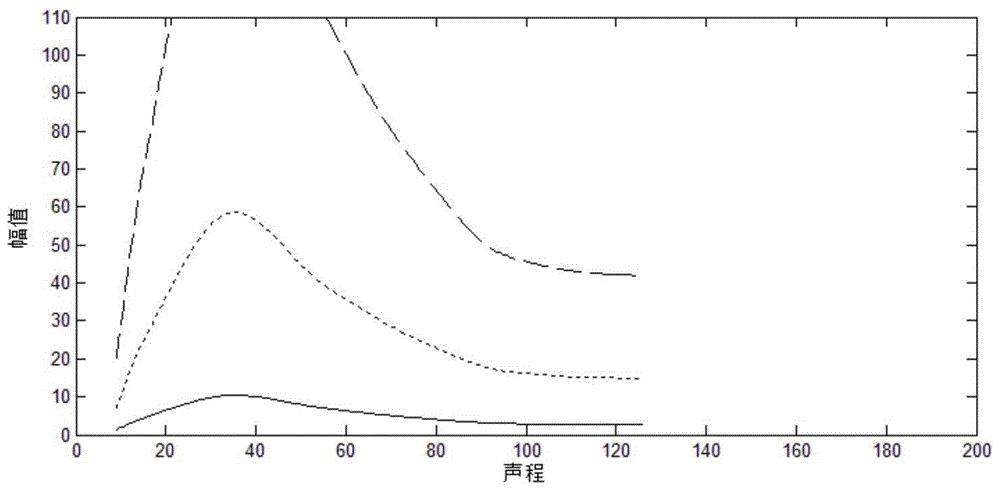

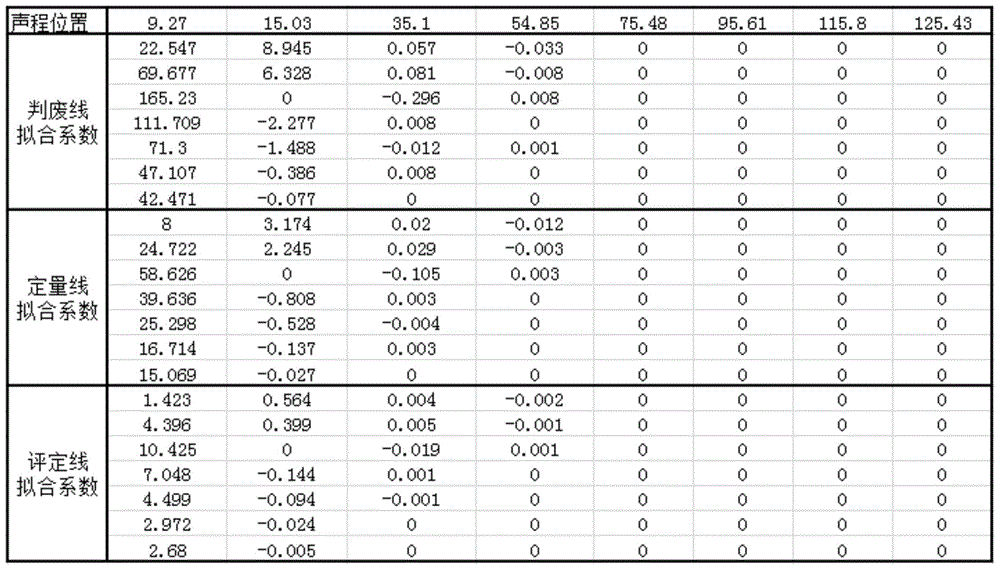

[0031] Step 2. Determine the DAC curve mode and curve fitting method, collect the echo amplitude and sound path data of defects at different depths, and fit the amplitude and sound path data according to the DAC curve mode and curve fitting method selected above to complete the DAC curve:

[0032] There are many types of DAC ...

Embodiment 2

[0047] A kind of ultrasonic C-scan imaging method based on DAC curve, concrete steps are as follows:

[0048] Step 1. Select a test block with the same material as the workpiece to be inspected, and the test block has more than 3 defects with the same aperture and different depths:

[0049] Example 2 of the present invention The material of the inspected workpiece is a magnesium alloy. A test block of the same material is selected. The regular reflector in the test block is a flat-bottomed hole with an equivalent of 1.2mm and 7 different depths, respectively 2.5mm, 7.5mm, and 20mm. , 50mm, 80mm, 90mm, 100mm.

[0050] Step 2. Determine the DAC curve mode and curve fitting method, collect the echo amplitude and sound path data of defects at different depths, and convert the echo amplitude and sound path data of defects at different depths according to the DAC curve mode and curve fitting method selected above Fitting to complete the DAC curve:

[0051] The DAC curve selects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com