Method for identifying muscat production place based on mineral element fingerprint technology

A technology of Muscat grapes and production areas, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of few production areas of Muscat grapes, and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

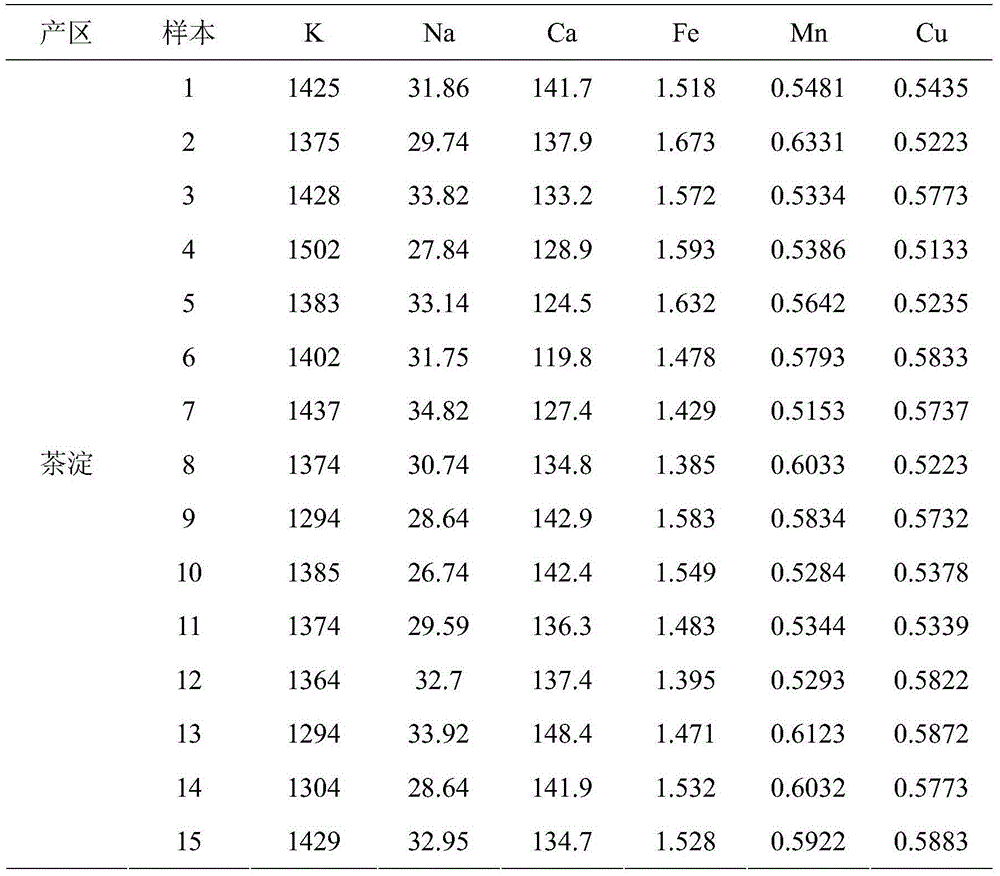

[0026] (1) Sample collection

[0027] In September 2013, farmers were randomly selected in the Chadian production area, and 2kg of grape samples were collected from their fields, numbered, as a sample; a total of 15 samples were collected, and 500g of each sample was taken as an analysis sample.

[0028] (2) Sample cleaning, drying and homogenization

[0029] The samples were washed with tap water and ultrapure water successively, and put into air-permeable plastic baskets to dry. After drying, take out the grape seeds and beat them into a homogenous slurry with a blender.

[0030] (3) Sample digestion

[0031] Accurately weigh 10.00g of the homogenate sample, put it into a 50mL glass digestion tube, add 10mL of concentrated nitric acid, cover it, let it stand for 4 hours, and then put it on a porous digestion furnace (ED36, Beijing Labtech Co., Ltd.) Heat and digest at 150°C. After the sample is digested and clear, open the glass cover, heat and steam at 120°C until nearl...

Embodiment 2

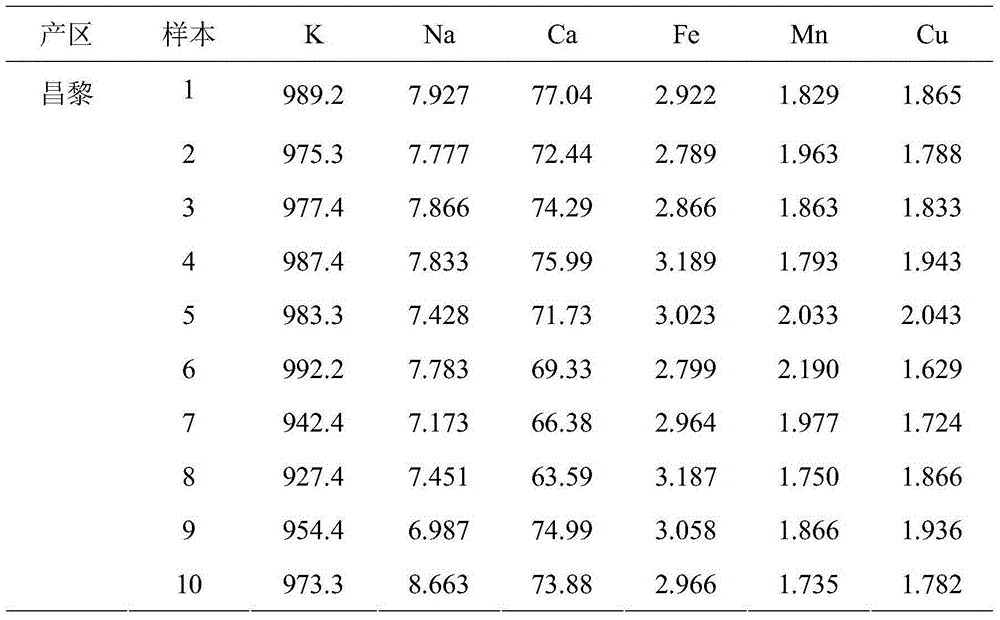

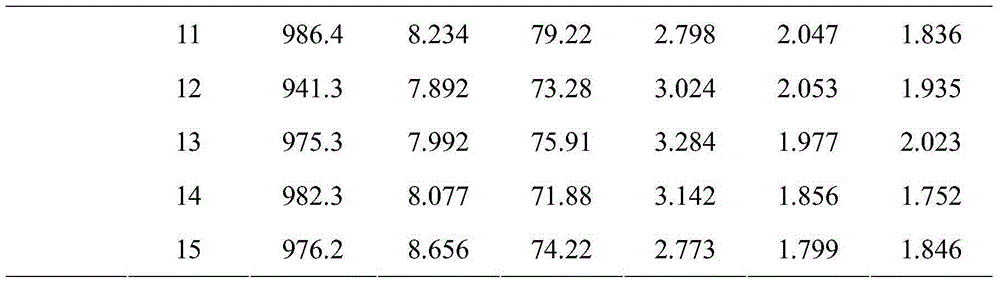

[0047] (1) Sample collection

[0048] In September 2013, farmers were randomly selected in the Muscat grape producing area in Changli, and 2kg of grape samples were collected from their fields, numbered, as a sample; a total of 15 samples were collected, and 500g of each sample was taken as an analysis sample.

[0049] (2) Sample cleaning, drying and homogenization

[0050] The samples were washed with tap water and ultrapure water successively, and put into air-permeable plastic baskets to dry. After drying, take out the grape seeds and beat them into a homogenous slurry with a blender.

[0051] (3) Sample digestion

[0052] Accurately weigh 10.00g of the homogenate sample, put it into a 50mL glass digestion tube, add 10mL of concentrated nitric acid, cover it, let it stand for 4 hours, and then put it on a porous digestion furnace (ED36, Beijing Labtech Co., Ltd.) Heat and digest at 150°C. After the sample is digested and clear, open the glass cover, heat and steam at 12...

Embodiment 3

[0068] (1) Sample collection

[0069] In September 2013, farmers were randomly selected in the Muscat grape producing area of Daze Mountain, and 2kg of grape samples were collected from their fields, numbered, as a sample; a total of 15 samples were collected, and 500g of each sample was taken as an analysis sample.

[0070] (2) Sample cleaning, drying and homogenization

[0071] The samples were washed with tap water and ultrapure water successively, and put into air-permeable plastic baskets to dry. After drying, take out the grape seeds and beat them into a homogenous slurry with a blender.

[0072] (3) Sample digestion

[0073] Accurately weigh 10.00g of the homogenate sample, put it into a 50mL glass digestion tube, add 10mL of concentrated nitric acid, cover it, let it stand for 4 hours, and then put it on a porous digestion furnace (ED36, Beijing Labtech Co., Ltd.) Heat and digest at 150°C. After the sample is digested and clear, open the glass cover, heat and ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com