Mixed modeling method and system based on combination of process priors and data-driven model

A data-driven model, combined with process technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as simple model structure, high constraints on modeling objects, and discarding useful information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

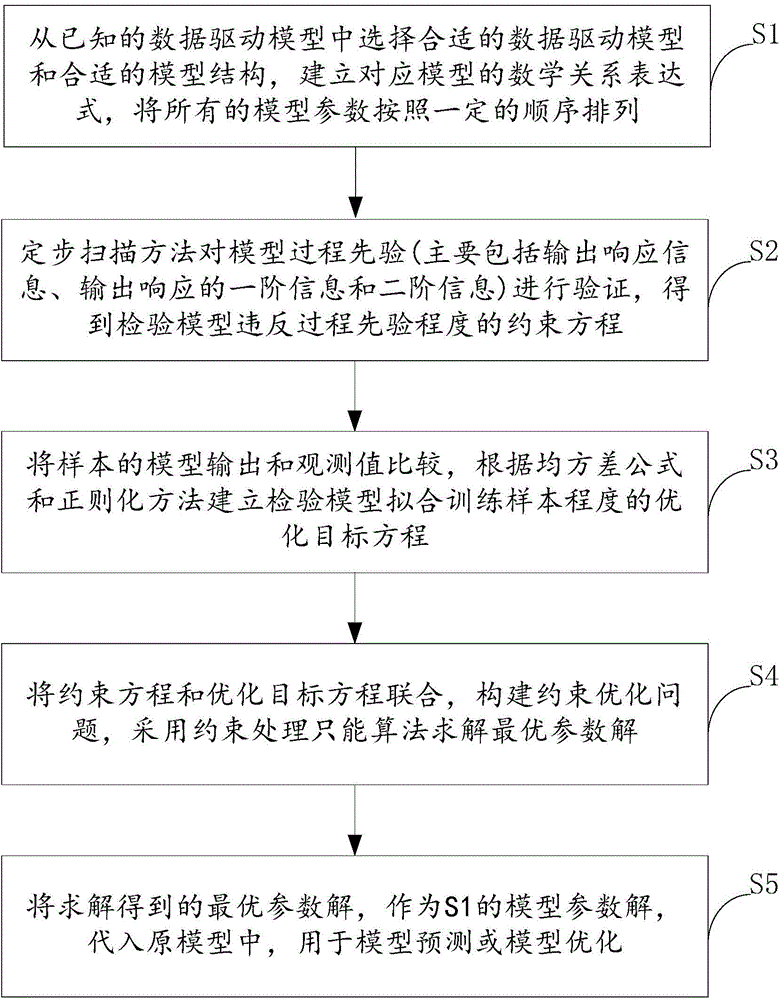

[0087] see image 3 , the present invention proposes a hybrid modeling method combining process priors and data-driven models, the specific steps are as follows:

[0088] [Step S1] Select a suitable data-driven model and a suitable model structure from known data-driven models, establish a mathematical relational expression of the corresponding model, and arrange all model parameters in a certain order.

[0089] The model mathematical relationship expression of step S1 Arrange par with model parameters: select a data-driven model, generally we often choose BP neural network model, response surface model, support vector machine, etc.

[0090] For the BP neural network model, its model input and output relationship is:

[0091] y ^ l ( p a r , X ) = f h ...

Embodiment 2

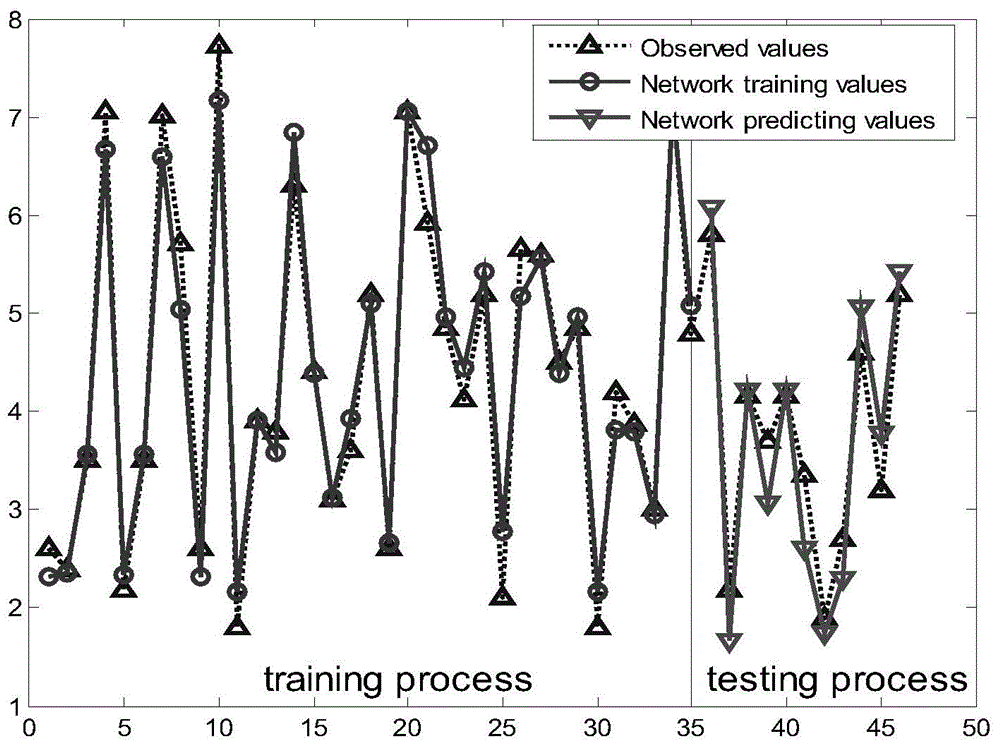

[0146] The description of the following examples will help to understand the present invention, but does not limit the content of the present invention. see figure 2 , this embodiment realizes the estimation of the average particle size of the nanofiltration membrane sol based on the hydrolysis temperature, the amount of glycerin added and the amount of complexing agent added, and the influence of input variables on the particle size of the sol is shown in Table 1. The nanofiltration membrane sol preparation process studied in this example is a steady state process, and the process data are collected from 46 groups of samples obtained in the experiment (sol particle size stability performance data acquisition period is long (about one month), and a large number of samples cannot be obtained). Other variable parameters are as follows: the molar ratio of the precursor is Zr:Ti=4, the molar ratio of the precursor to water is 1:555, the sol concentration is 0.1mol / L, and the comp...

Embodiment 3

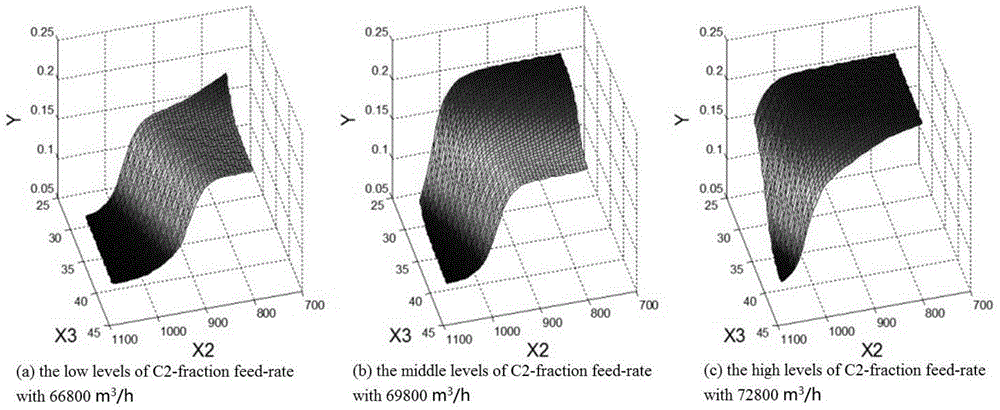

[0159] The description of the following examples will help to understand the present invention, but does not limit the content of the present invention. The analysis object of this example is a reactor of the acetylene hydrogenation reactor of ethylene production unit (such as image 3 colored circle). In this paper, the feed rate of C2 fraction, the feed rate of hydrogen and the temperature difference between the inlet and outlet of the first-stage reaction tank are selected as the easy-to-measure (independent variables) of the soft sensor, and the soft sensor model is established to estimate the concentration of acetylene at the outlet of the first-stage reaction tank.

[0160] The acetylene soft measurement of a section of the reaction tank studied in this example, the process data are collected from 40 groups of samples obtained from the experiment. Divide 40 groups of samples into 2 parts, randomly select 30 groups as training samples, and 10 groups as test samples. Sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com